Pouring device for long-span prestressed concrete shell with cylindrical inner wall

A concrete and prestressed technology, which is applied to unloading devices, roofs using flat/curved panels, buildings, etc., can solve the problems of not meeting the accuracy requirements of components, uneven thickness of concrete inner walls, and large diameter of roller shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

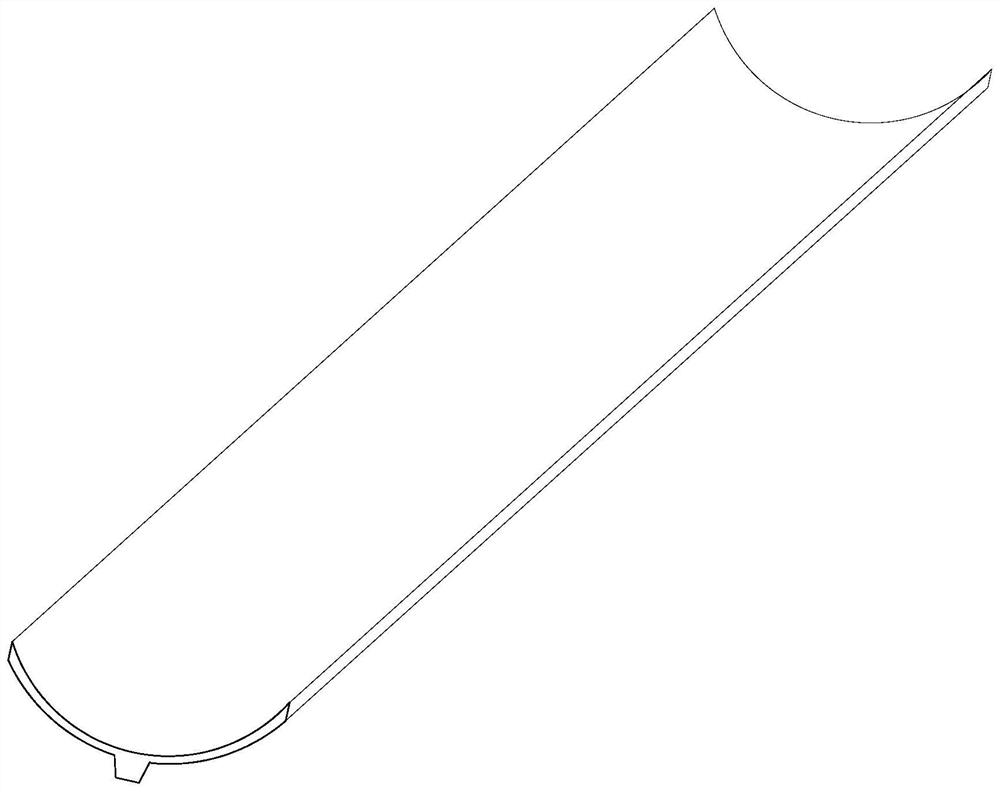

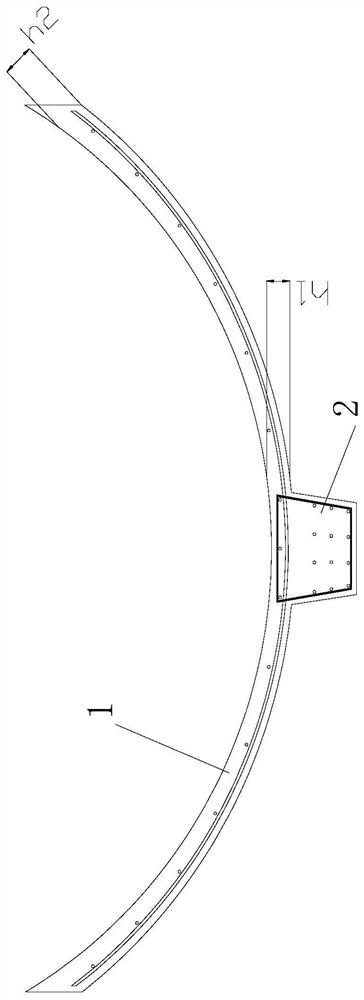

[0042] Such as Figure 1~2 The inner wall shown is a cylindrical long-span prestressed concrete shell plate, with a curved flange plate 1, and a main rib 2 is provided at the center of the outer peripheral surface of the flange plate 1, and the main rib 2 is along the length direction of the flange plate 1 Setting, the flange plate 1 is a 1 / 3 circular arc plate; the cross section of the main rib 2 is trapezoidal, and the large end of the main rib 2 is connected with the flange plate 1; when the span of the flange plate 1 is <21m, the flange plate 1 Thickness h2 of end portion = central thickness h1 of flange plate 1 .

[0043] The inner steel strands 16 are concentratedly arranged in the main rib 2, and the inner steel strands 16 are under tension and the flange plate 1 is under compression, resisting the bending moment of the concrete shell.

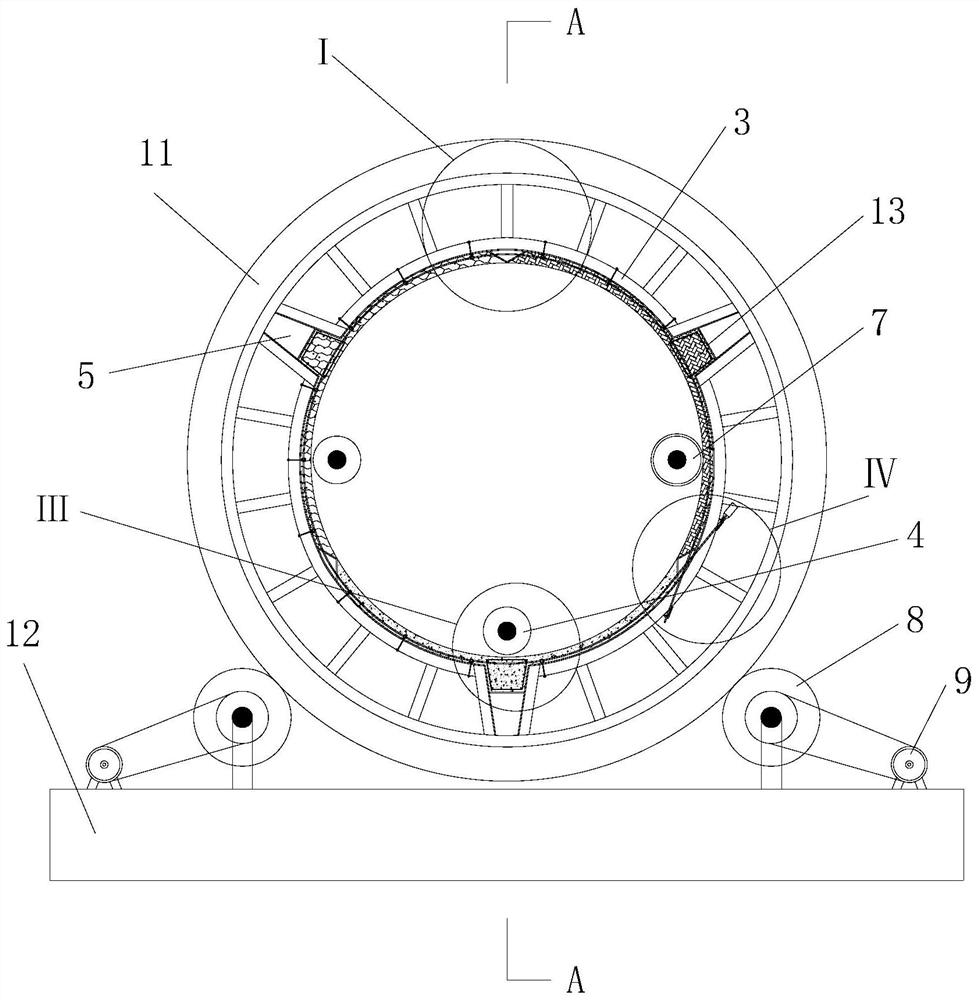

[0044] Such as Figure 3-5 , Figures 9 to 11As shown, a pouring device for pouring the above-mentioned large-span prestressed conc...

Embodiment 2

[0056] The difference from Embodiment 1 is that when the span of the flange plate 1 is ≥ 21 m, the thickness h2 of the end of the flange plate 1 > the thickness h1 of the center of the flange plate 1 can prevent the upper end of the flange plate 1 from being unstable.

[0057] The side formwork unit in the pouring device is a square pipe with variable cross-section bent into an arc-shaped pipe, and the thickness h3 of the side formwork unit is consistent with the thickness direction of the flange plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com