Scratch-proof fabricated wallboard

A prefabricated, anti-scratch technology, applied in clothing, floor, covering/lining, etc., can solve the problems of lack of protective structure, easy to be scratched, etc., to expand the usable area, beautiful main wall panels and auxiliary wall panels , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

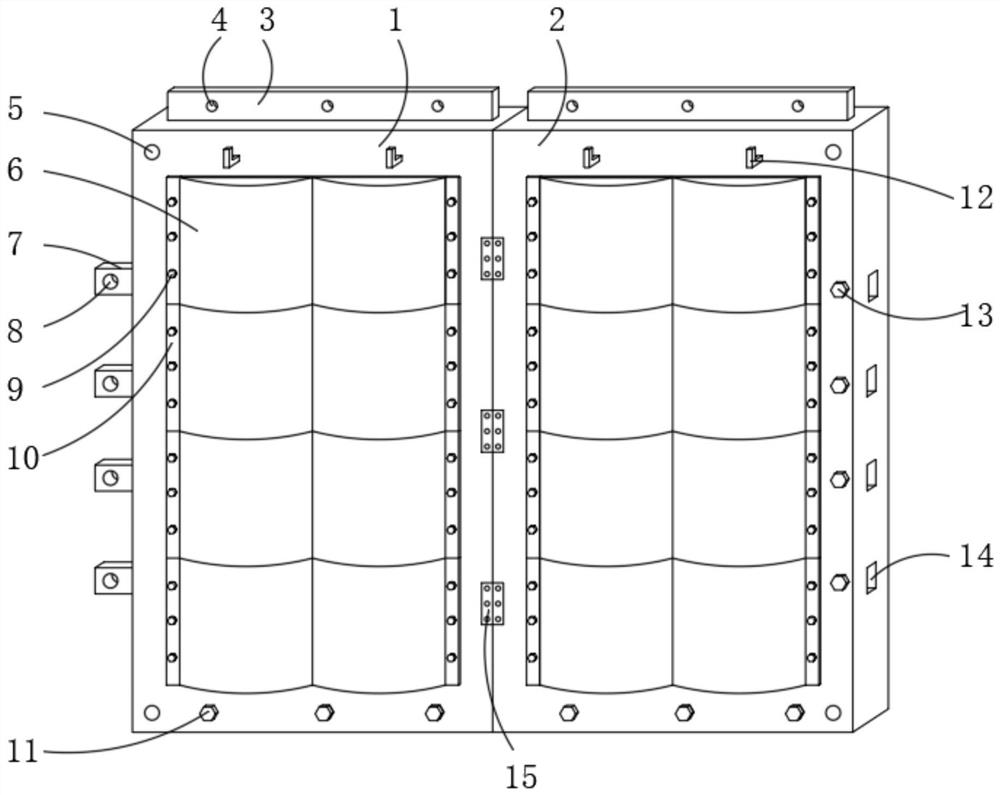

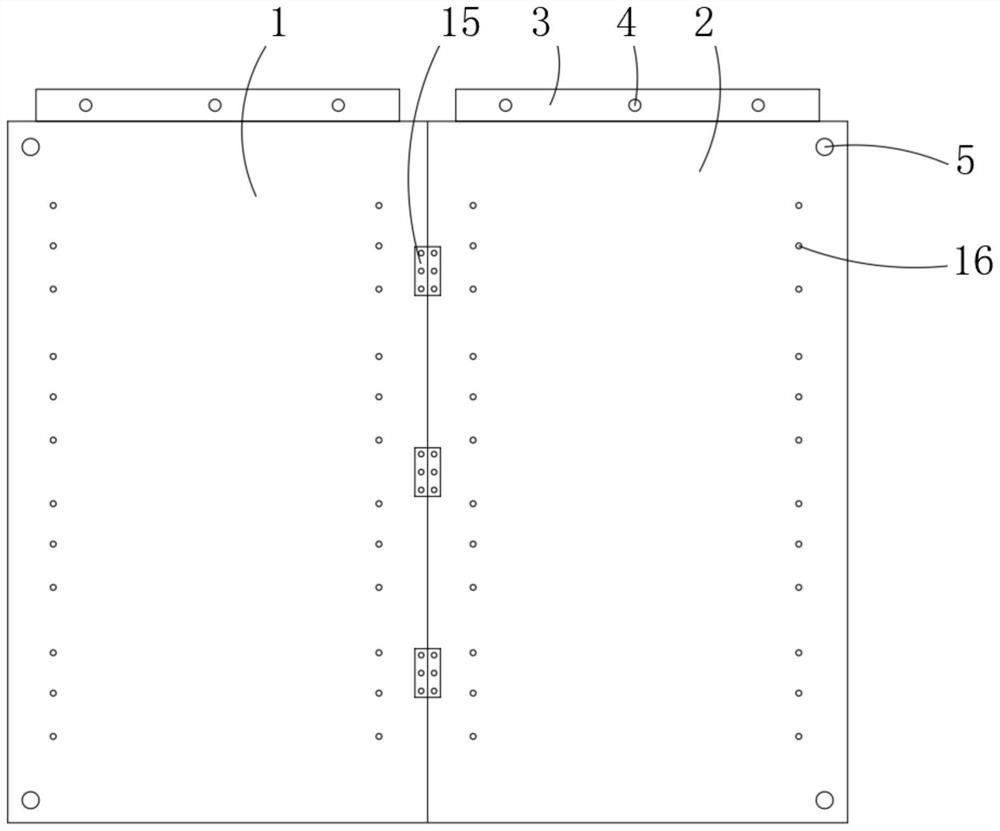

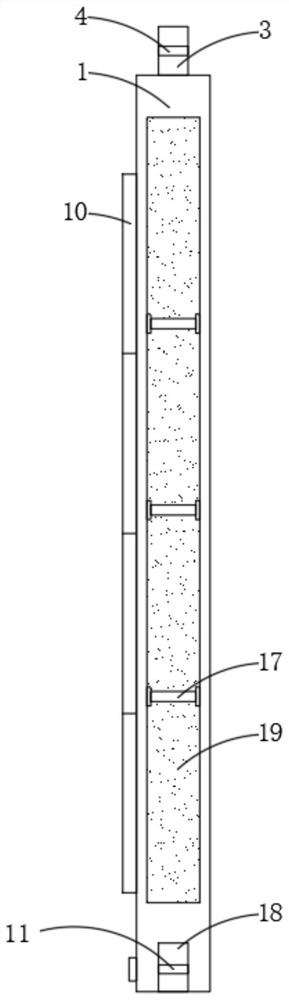

[0038] Embodiment one: if Figure 1-4 The present embodiment shown is a method of using an anti-scratch assembled wallboard: when in use, one of the wallboards is installed on the wall with screws through the installation hole 5, and then through the upper and lower connection structures and the left and right connection structures Another wallboard can be combined with it to expand the use area of the wallboard. After the wallboard is installed, align the main locking bolt 9 on the installation board 10 with the front end of the main wallboard 1 and the auxiliary wallboard 2. The main threaded hole 16 can install the mounting plate 10 on the main wallboard 1 and the auxiliary wallboard 2, so that the effect of installing the soft bag 6 can be achieved.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap