Regeneration method and device of particle catcher

A particle trap and regeneration device technology, which is applied to the electronic control of noise reduction devices, exhaust devices, exhaust treatment devices, etc., can solve the problems of non-metallic parts burning, vehicle spontaneous combustion, etc., to improve efficiency and reduce spontaneous combustion. risk, avoiding the effect of overheating in the front cabin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

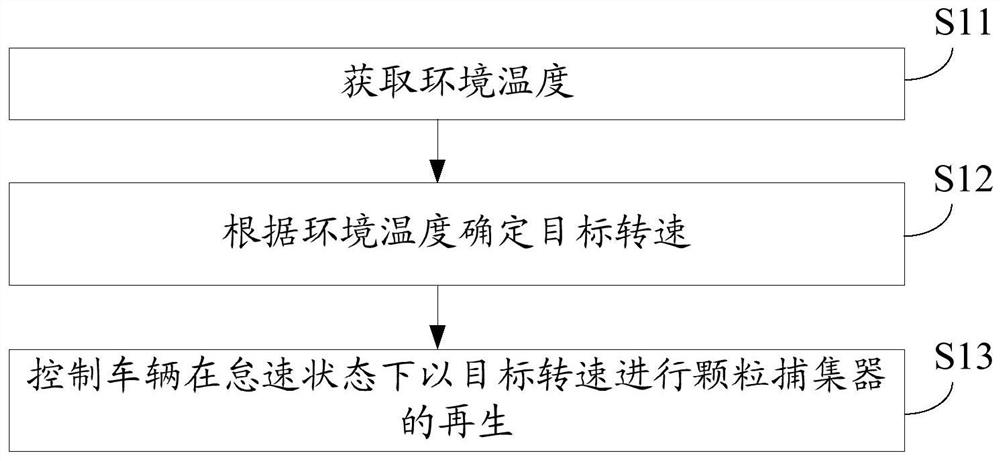

[0043] figure 1 It is a flowchart of a method for regenerating a particle trap provided by an embodiment of the present disclosure. Such as figure 1 As shown, the method includes:

[0044] In step S11, the ambient temperature is acquired.

[0045] In step S12, the target rotational speed is determined according to the ambient temperature.

[0046] Wherein, the target rotational speed is the rotational speed of the engine when the particulate filter is being regenerated.

[0047] In step S13 , the vehicle is controlled to perform regeneration of the particulate trap at the target rotational speed in an idling state.

[0048] By obtaining the ambient temperature, and then determining the regeneration of the particle filter accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com