Smoke intensity control method for small excavator

A control method and technology for excavators, which are applied in engine control, electrical control, fuel injection control, etc., can solve problems such as affecting the operation performance of the whole machine and reducing the operating efficiency of the whole machine, so as to achieve no change in the cost of the whole machine and eliminate the need for the whole machine. The effect of poor performance and realization of benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

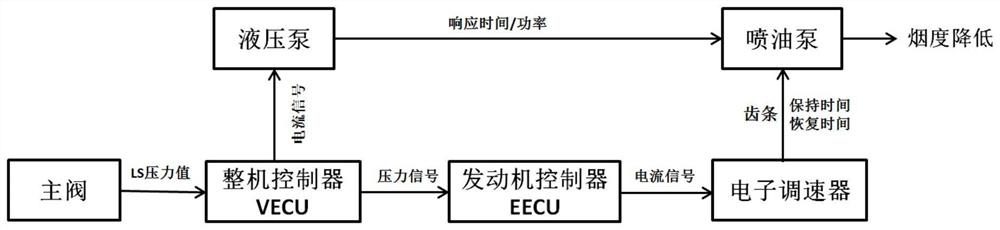

[0015] like figure 1 As shown, the smoke control method of the small excavator described in the present invention transmits the load signal of the whole machine through the communication between the whole machine controller VECU and the engine ECU, and the whole machine controller VECU adjusts the corresponding time and absorbed power of the hydraulic pump, and the engine EECU simultaneously By adjusting the current of the electronic governor and controlling the holding and recovery time of the fuel injection rack, the black smoke emission of the whole machine can be reduced, including the following specific steps:

[0016] Step 1. The whole machine controller VECU collects the pressure value of the LS port on the main valve or the pressure value of the hydraulic pump. The whole machine controller VECU compares the collected pressure value with the trigger value set by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com