Gear backlash adjusting structure and adjusting method thereof

A gear backlash and structure adjustment technology, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of no adjustment, time-consuming and labor-intensive adjustment of backlash, and improve installation accuracy and adjustment. The effect of improving precision and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

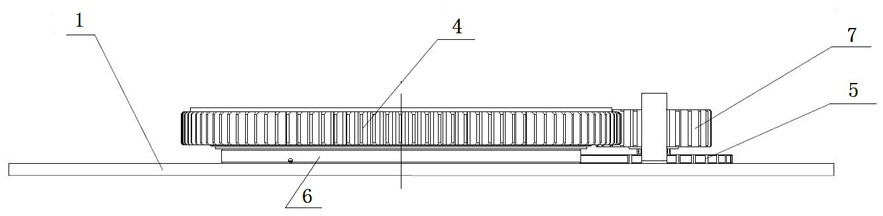

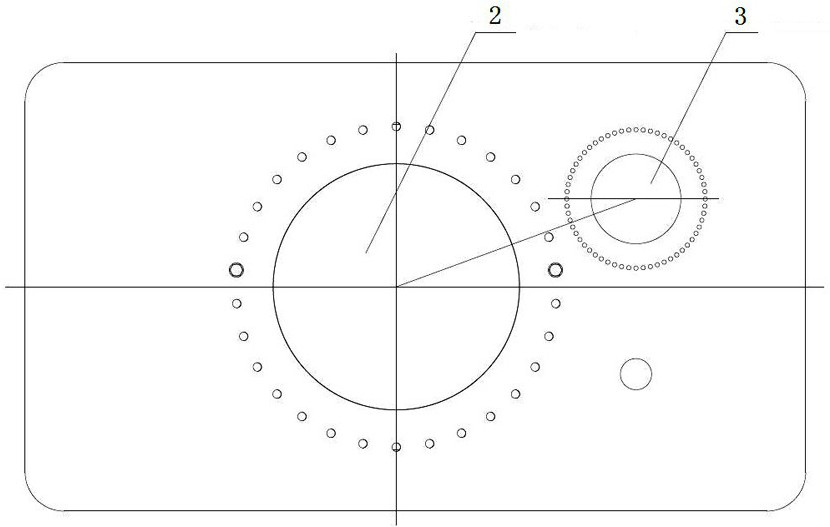

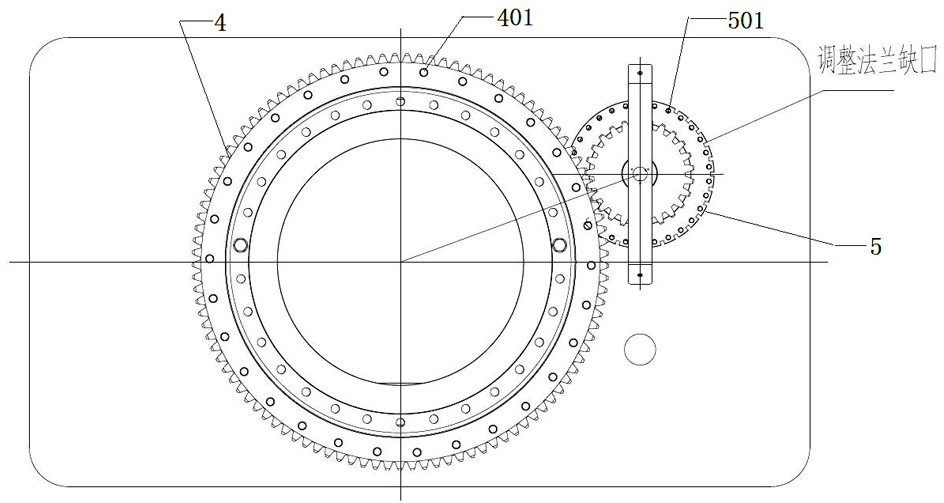

[0031] like Figure 1 to Figure 4 As shown, a gear backlash adjustment structure of the present invention includes a platform 1, and the platform 1 is provided with a slewing bearing installation hole 2 and an adjustment flange installation hole 3, and the slewing bearing installation hole 2 is fixedly connected with a slewing bearing 4. An adjusting flange 5 is fixedly connected to the adjusting flange mounting hole 3, a transition flange 6 is arranged between the slewing bearing 4 and the platform 1, and a motor and a speed reducer are fixedly connected under the adjusting flange 5. machine, the adjustment flange 5 is provided with a pinion 7, the center of the pinion 7 does not coincide with the center of the adjustment flange 5, the pinion 7 is meshed with the slewing bearing 4, and the flower of the pinion 7 The key is fixed on the shaft end of the reducer, the adjustment flange 5 is provided with a gap, and the adjustment flange 5 is evenly provided with a plurality of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com