Gear recognition system and method

A technology of identification system and gear position, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of high equipment cost, influence, poor anti-magnetic field interference ability, etc., and achieve high identification and positioning accuracy , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

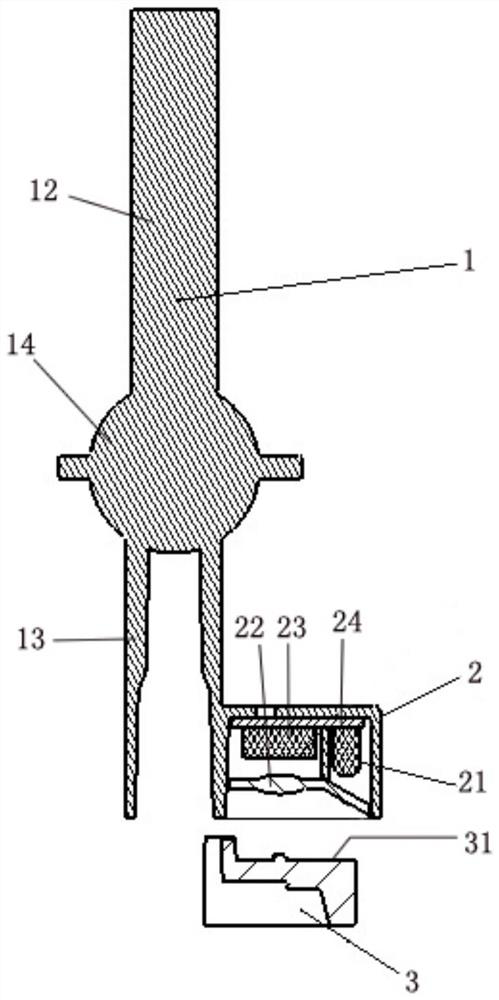

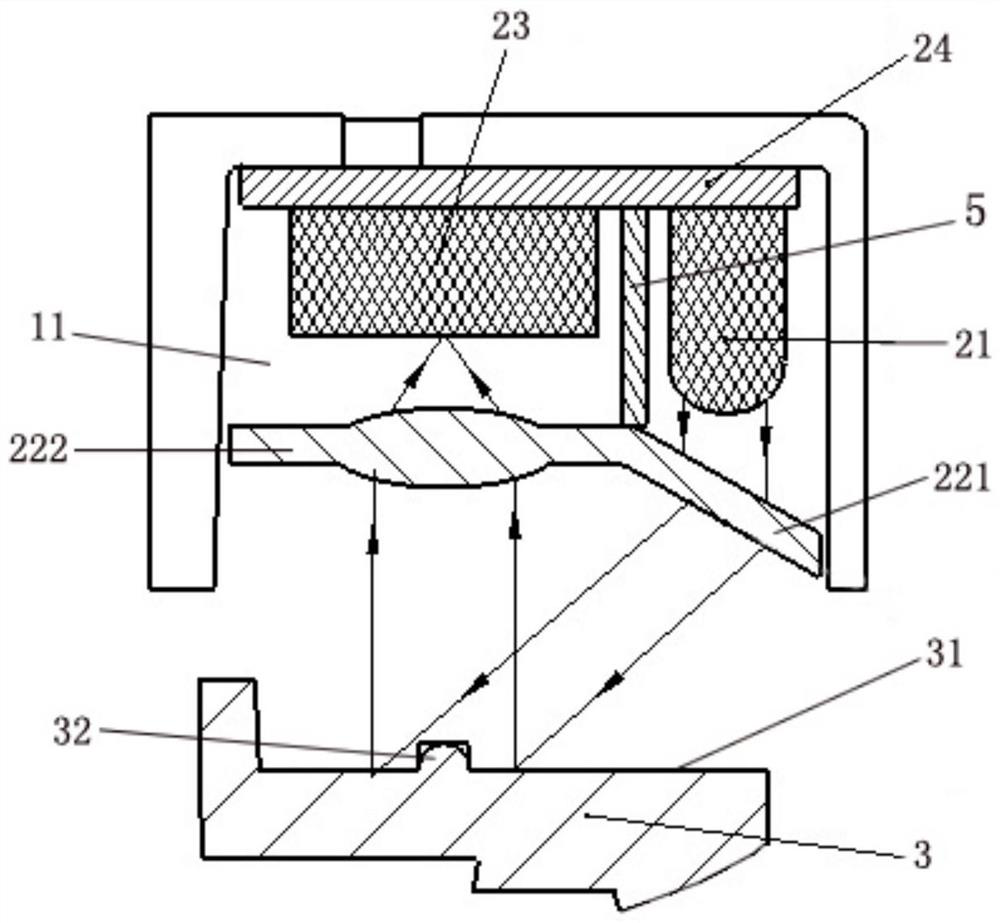

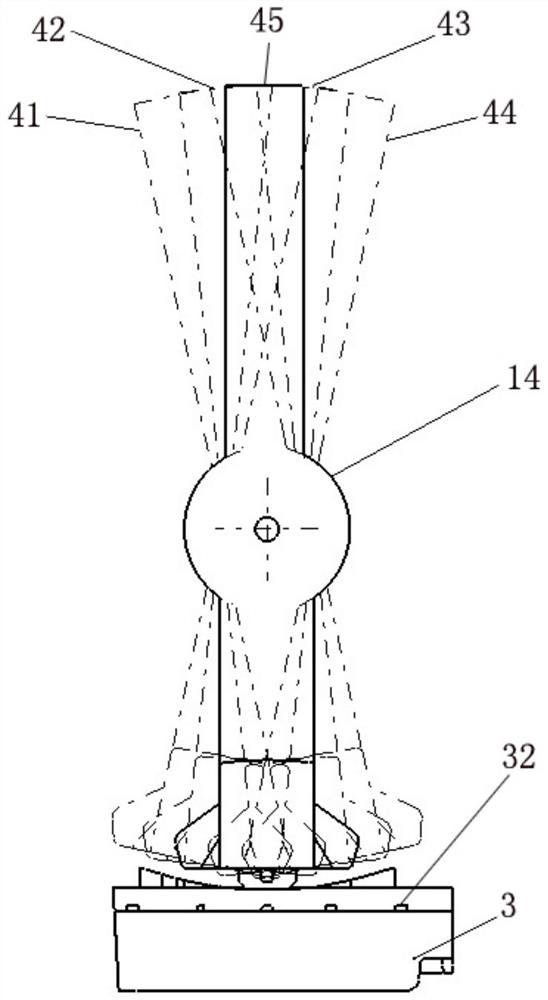

[0024] Please refer to the attached figure 1 -3, a gear recognition system provided by the present invention, which includes a shift lever 1, an identification component 2 relatively fixedly connected to the shift lever 1, and a reference member 3 as a frame of reference, the shift lever 1 and the identification component 2 rotate or translate relative to the reference member 3, the reference component 3 includes a reflective panel 31; the identification component 2 includes a light emitting element 21, a light guide element 22, an optical sensor 23 and an image analysis chip, The light emitting element 21 and the optical sensor 23 are fixedly arranged on the same side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com