Compression ratio measuring device

A technology for measuring devices and compression ratios, applied to measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as low labor efficiency, easy damage to insulation, hidden dangers of product quality, etc., to improve production efficiency , saving labor costs, shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

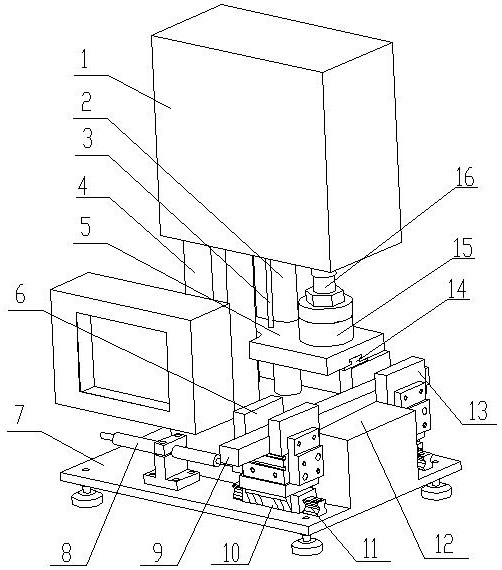

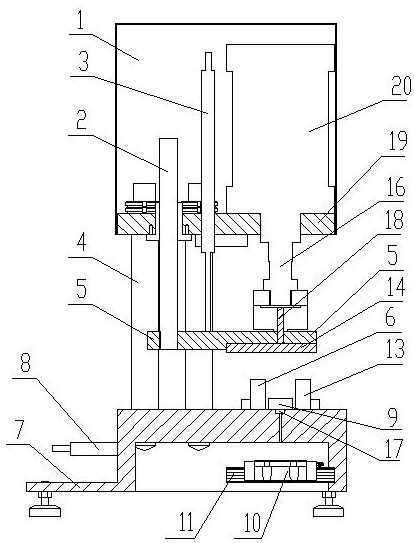

[0018] As shown in the figure, this embodiment includes a base 7 , and a workbench 12 is provided in the middle part of the upper surface of the base 7 . The bases 7 on both sides of the workbench are lower than the workbench 12, and guide rails 11 arranged in the front and rear directions are installed on them, and there are sliding seats 10 to cooperate with the two guide rails 11, and the movement of the sample 9 is installed above each sliding seat 10. The splint 13 has a fixed splint 6 on the base 7 corresponding to the position of each movable splint 13 . There is a transverse moving cylinder 8 on both sides of the rear of the base 7, and its piston rods are respectively connected with the sliding seat 10 on the same side to control the movable splint 13 to move back and forth, so that the movable splint 13 can be connected with the fixed splint on the same side. 6 fits the two ends of the sample 9 to clamp the sample 9, so that its position is fixed.

[0019] At the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com