Material ignition point test assessment device and assessment method

A technology of ignition point and test piece, which is used in measurement devices, analytical materials, thermal analysis of materials, etc., can solve the problems of limited and inability to provide material temperature performance data, and achieve shortened product processing and turnover cycles, sufficient assessment, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following embodiments in conjunction with the accompanying drawings and specific embodiments of the present invention will be further described in detail:

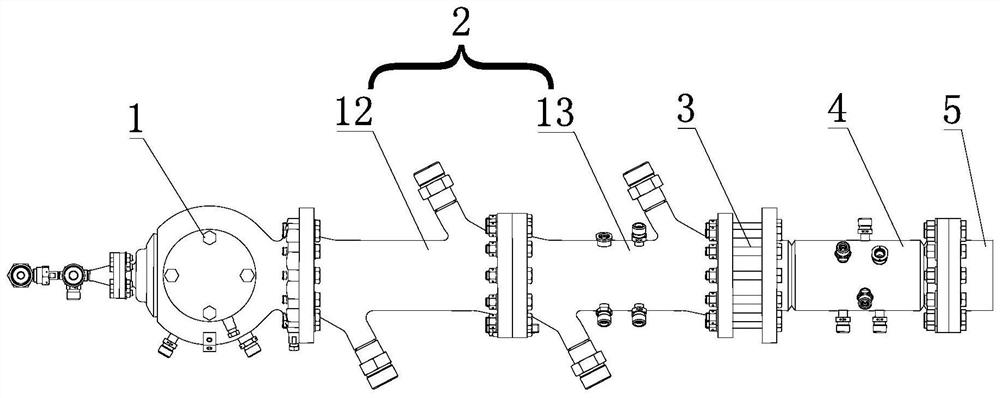

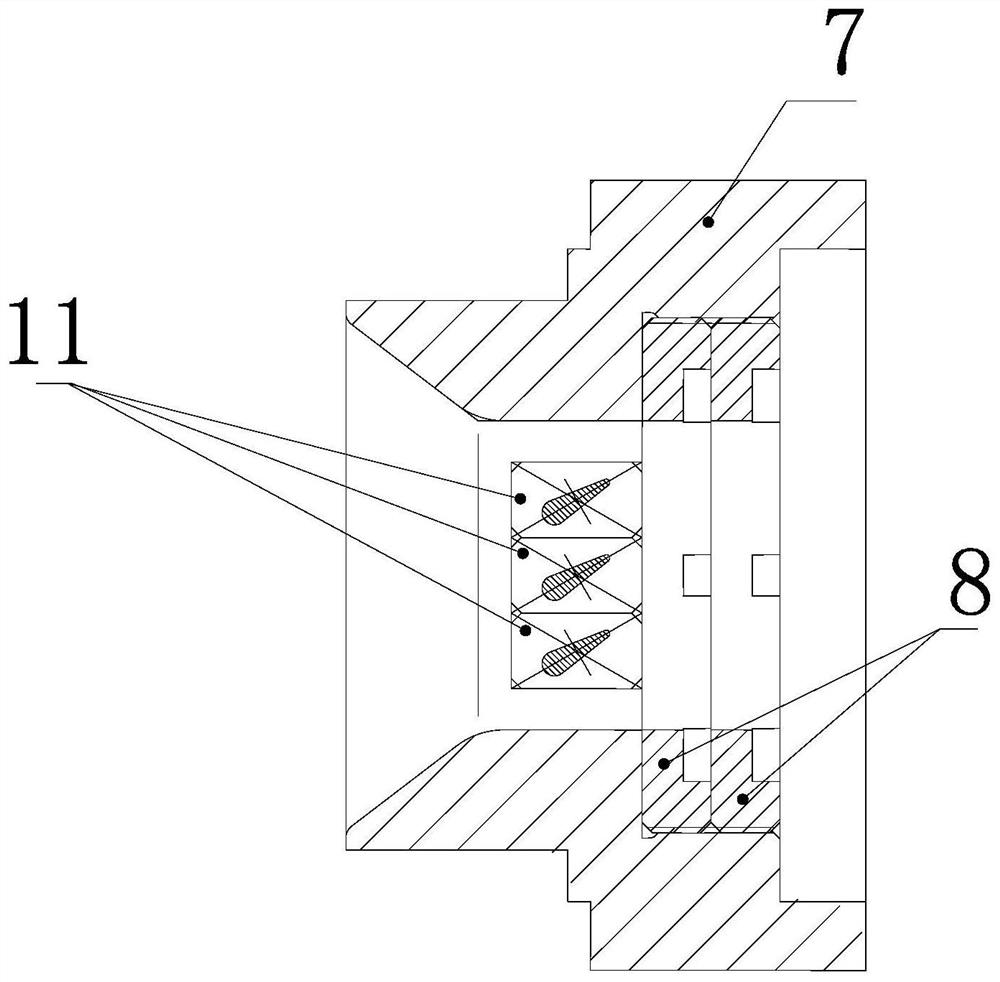

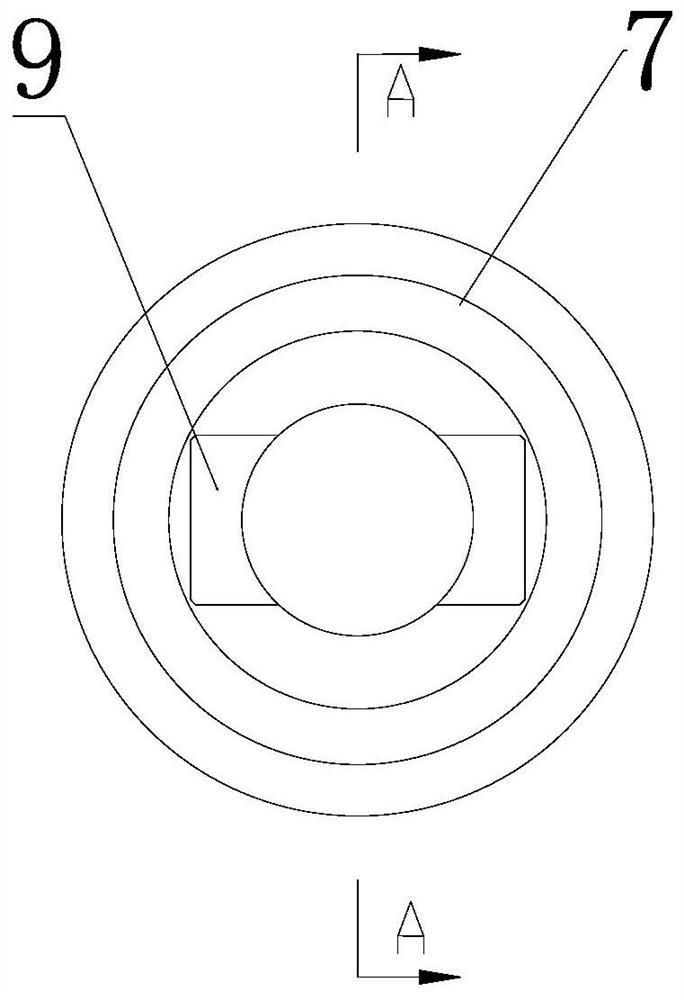

[0051] like Figure 1 - Figure 13 , The ignition point of a material testing apparatus comprising a gas generator sequentially assessment communication 1, a water-cooled section 2, the test piece holding section 3, section 4 and the process monitoring lance 5; cooled section 2, the specimen holder section 3, process monitoring section 4 and the nozzle 5 are made of a high temperature alloy.

[0052] A gas generator for providing a temperature high-pressure evaluation test pieces 11 to be oxygen-enriched gas, to assess the performance of the material temperature limit erosion in high pressure gas environment, the temperature of the oxygen-enriched gas may be supplied to the gas generator 1 enriched gas temperature provided to 800K ~ 900K, a pressure of 12 ~ 16MPa, an oxygen content higher than 89%, a flow rate of 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com