A wide rotor tooth bearingless switched reluctance motor power converter and control method

A technology of switched reluctance motor and power converter, which is applied in AC motor control, control system, magnetic circuit, etc., can solve the problems of increased cost of power converter, inability to track current, large motor torque ripple, etc. Torque problem, cost control, effect of improving running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

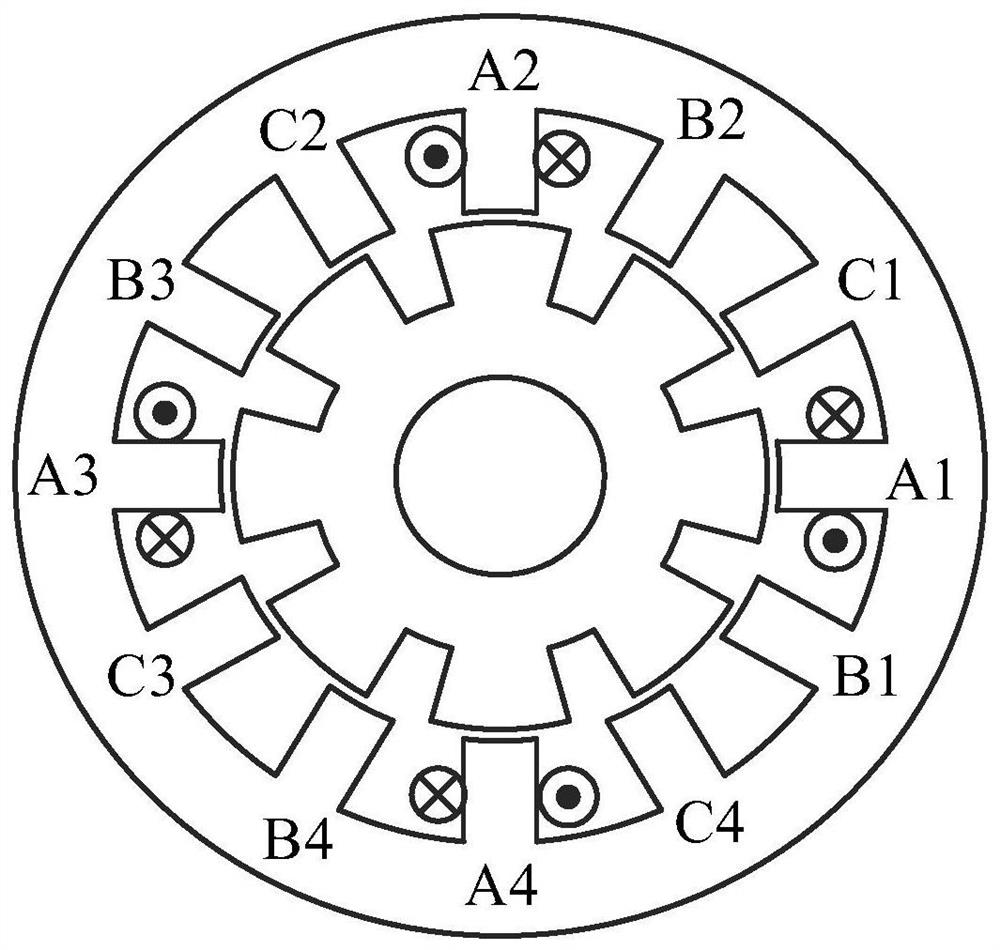

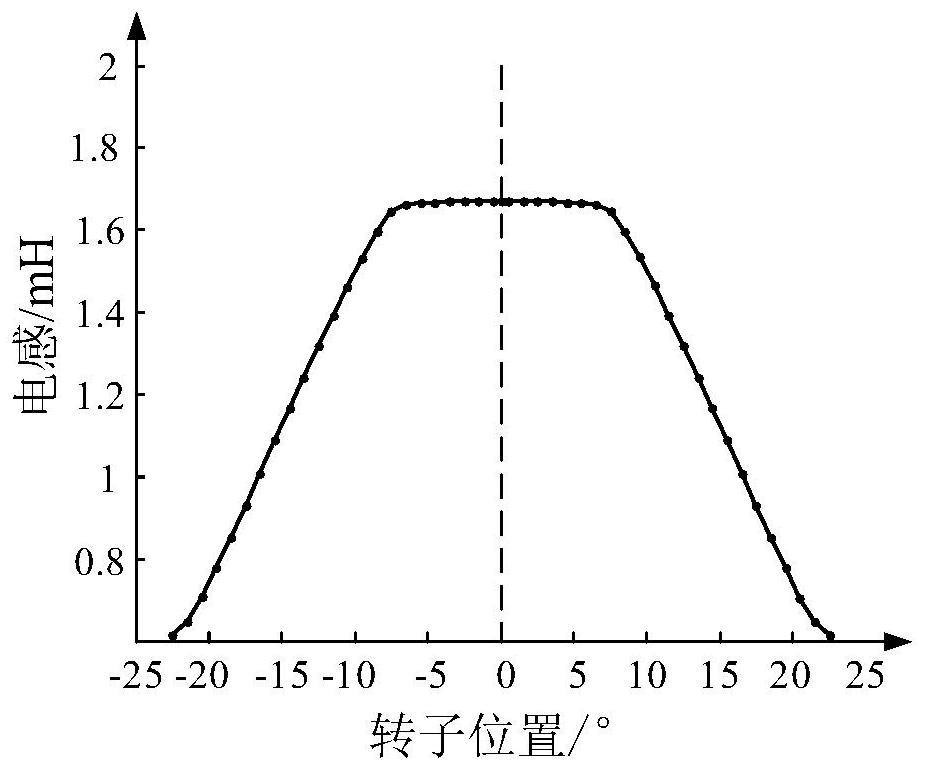

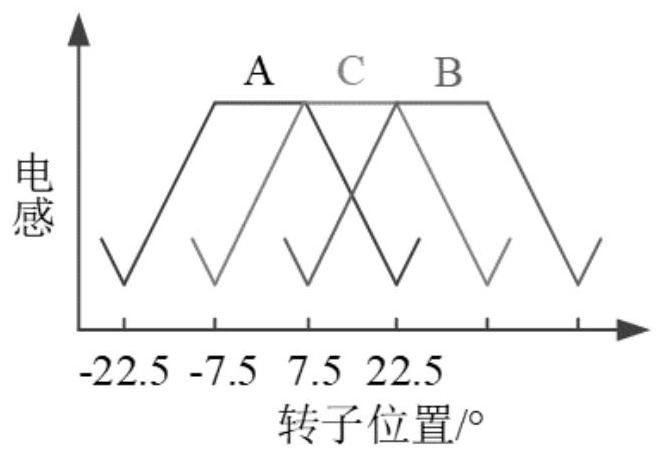

[0038] Such as Figure 1-4 A wide rotor tooth bearingless switched reluctance motor power converter shown, the motor structure is as followsfigure 1 As shown, it is a 12 / 8-pole single-winding motor, including 12 salient pole stator teeth, 8 salient pole rotor teeth, windings and a rotating shaft; the mechanical angle of the rotor pole arc is 30°, and the mechanical angle of the stator pole arc is 15°; each of the 12 stator teeth has a set of windings, the voltage and current of each winding can be controlled separately, the winding directions of the two windings at intervals of 90° are opposite, and the direction of the inflow current is the same; the four The magnetic field formed by the windings is distributed in NSNS, and the four stator windings every 90° form the one-phase winding of the motor; the 12 windings finally form three-phase windings with a spatial diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com