Milling equipment for automatic rice noodle production line

A technology of automatic production line and grinding equipment, applied in grain processing and other directions, can solve problems such as low production efficiency, and achieve the effect of improving finishing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

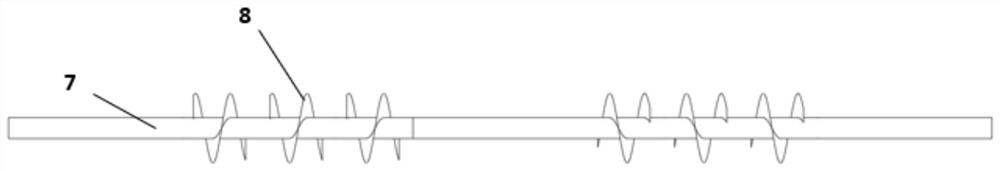

[0029] as attached Figure 1-3 As shown, the present embodiment exemplifies a milling equipment for a rice noodle automatic production line according to the present invention, including a silo 1 arranged from top to bottom, six parallel milling devices 2 and six parallel guides. The trough 3, the silo 1 includes a feed part 4 and a discharge part 5, the feed part 4 is located in the upper half of the silo 1, forming a "V"-shaped long groove with the big mouth facing upwards, and the feed part 4 is provided with a horizontal material distribution screw rod 6 parallel to the long groove side of the feeding part. The material distribution screw rod includes a long axis main body 7 and a screw blade 8. Both ends of the long axis main body 7 are connected to each other by bearings. The feeding part 4 is connected, and its exterior is driven by a motor to rotate around the axis line. There are no helical leaves in the middle and both ends of the long-axis main body 7, and the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com