Electrical equipment installation part surface coating drying and hanging device

A surface coating and electrical equipment technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of not satisfying mass production and low efficiency of drying equipment, and improve the drying speed , reduce microwave spillover, safe and reliable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

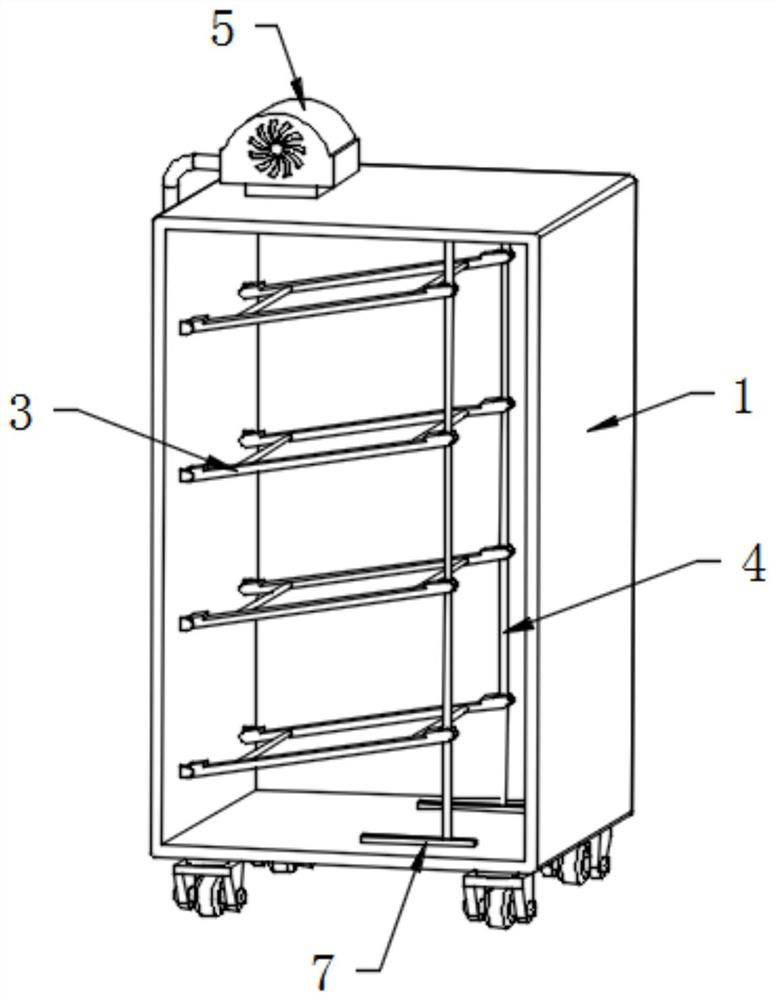

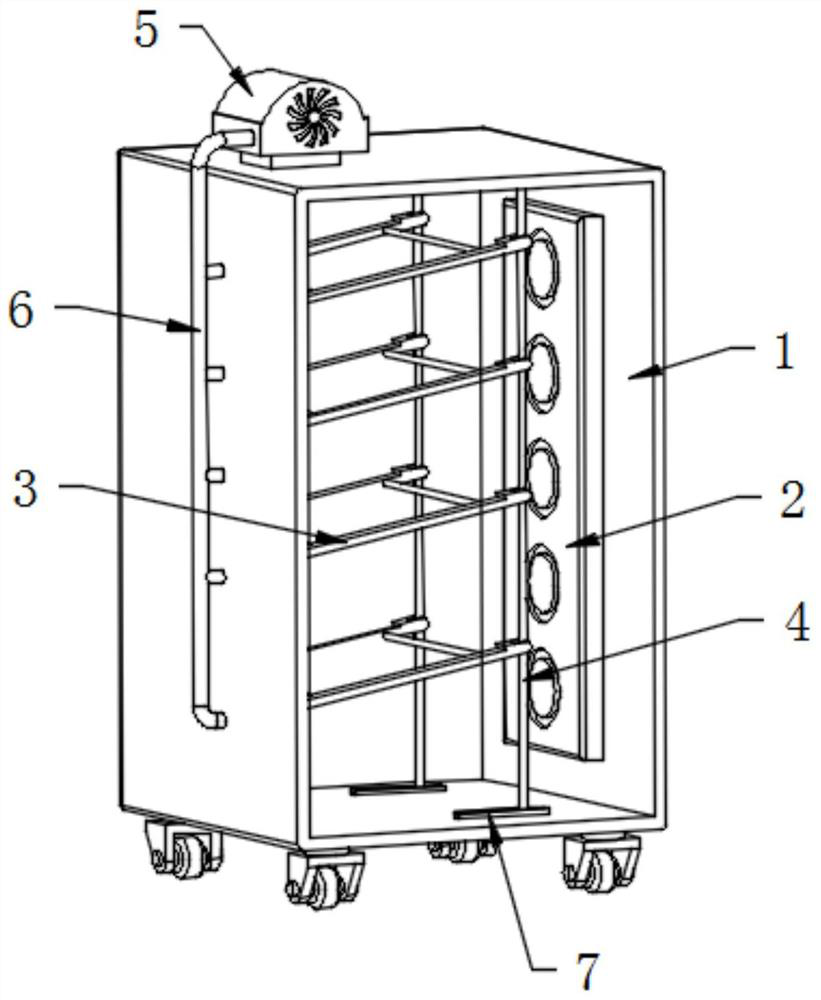

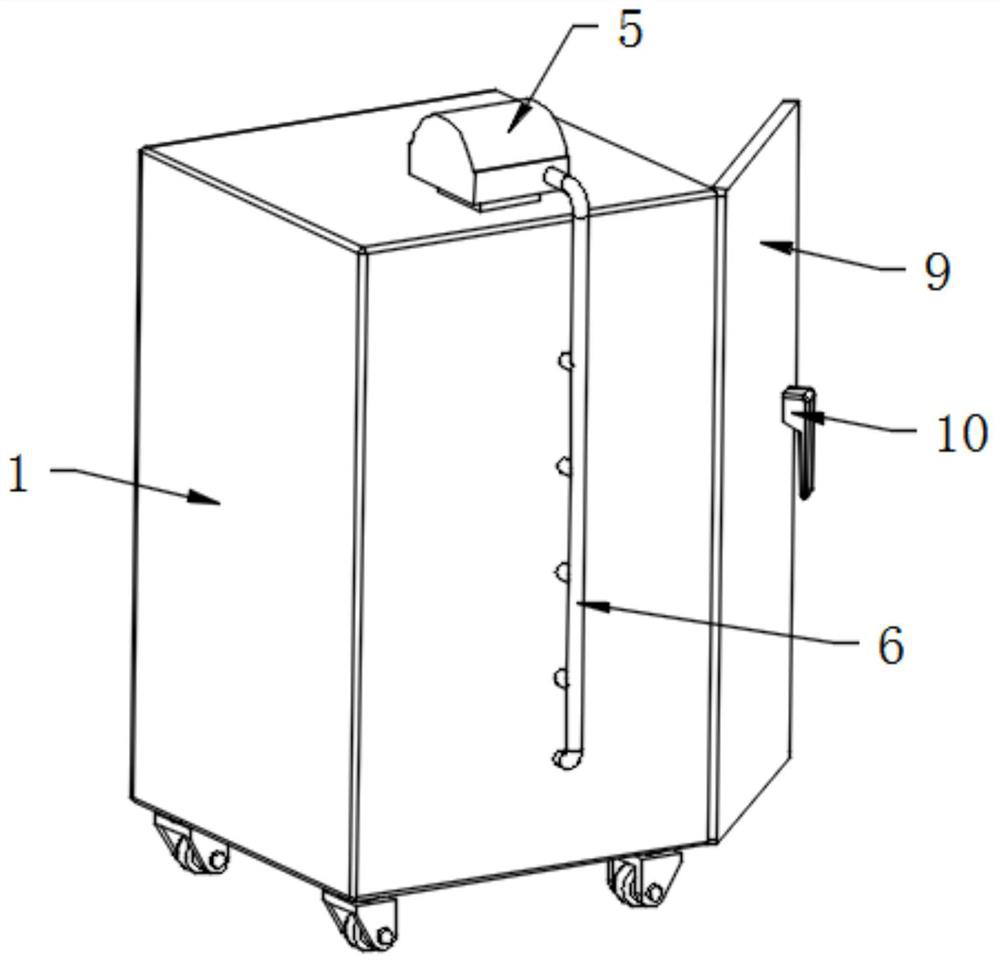

[0032] see Figure 1-5 , a surface coating drying mounting device for electrical equipment, including a cabinet body 1 and a microwave generator 2 fixedly arranged on the inner side surface wall of the cabinet body 1, and at least four mounting racks 3 are arranged in the cabinet body 1 One side of the mounting frame 3 is rotatably connected with the cabinet body 1, and the other side is provided with a limit rod 4. The top of the cabinet body 1 is fixedly provided with an air pump 5. The mounting frame 3 includes: two support rods 301, two support rods The rods 301 are connected to the cabinet 1 in rotation; the pipe body 302 is fixedly arranged between the two support rods 301, and the pipe body 302 has a plurality of suction cups 303, and the pipe body 302 communicates with the air pump 5 through the air pipe 6. There is a groove 304 on the support rod 301 , a plurality of suction cups 303 are evenly distributed along the axial direction of the pipe body 302 , and the plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com