Running wheel forging and pressing device of electric pole steel die

A pole steel mold and forging technology, applied in forging/pressing/hammer devices, driving devices of forging presses, swaging presses, etc., can solve the problem of high-temperature deformation of forging heads and molding dies, lower molding quality, and unfavorable service life and other issues, to achieve the effect of improving safety, increasing service life, and preventing damage due to excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

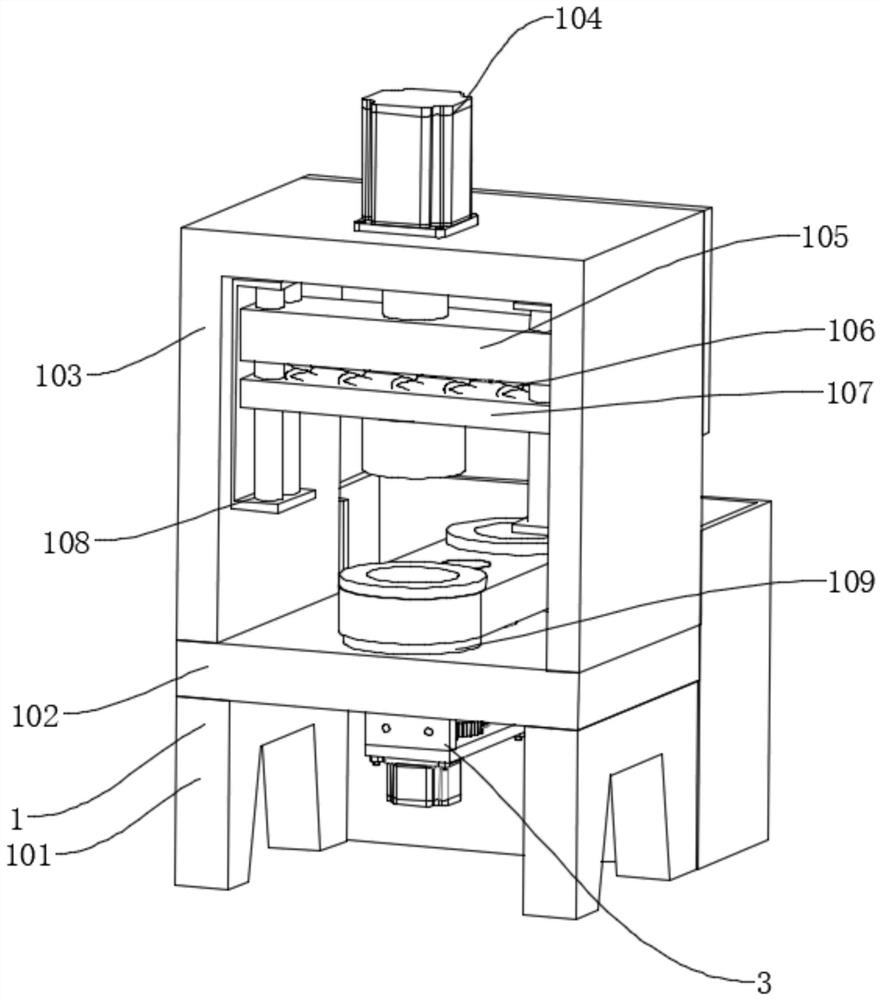

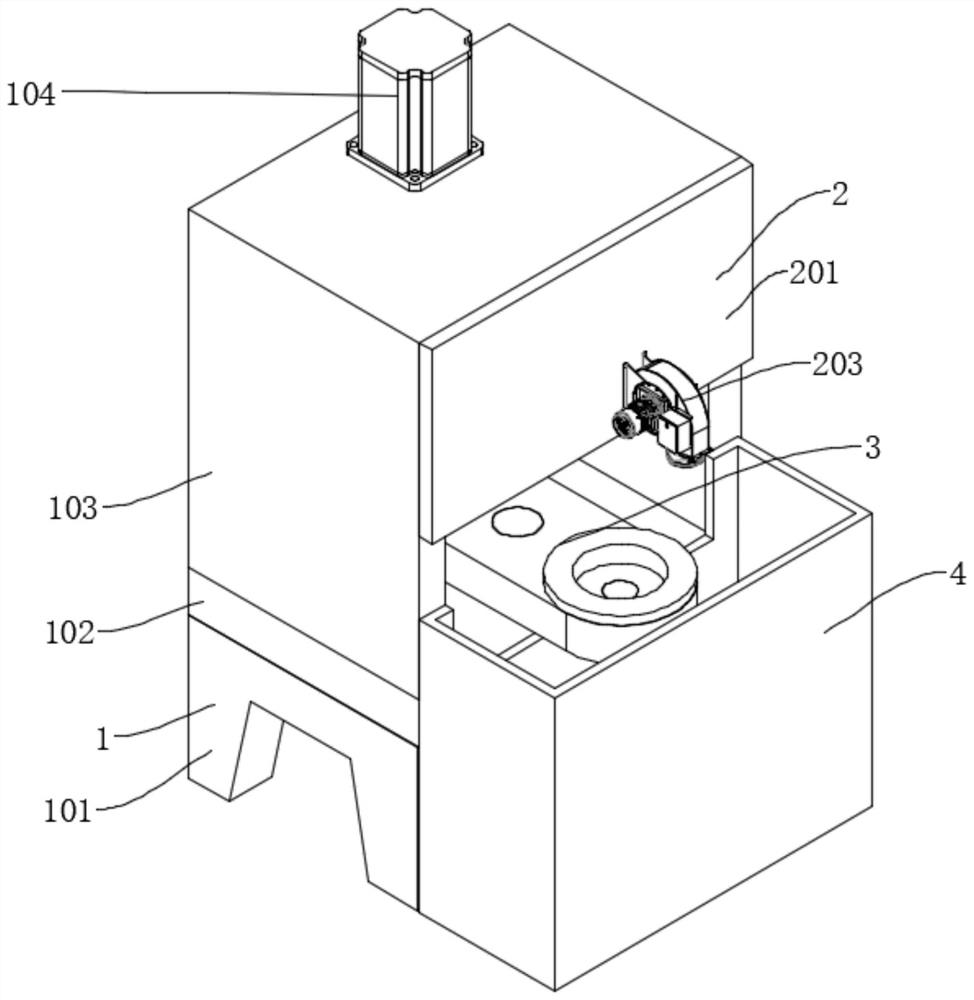

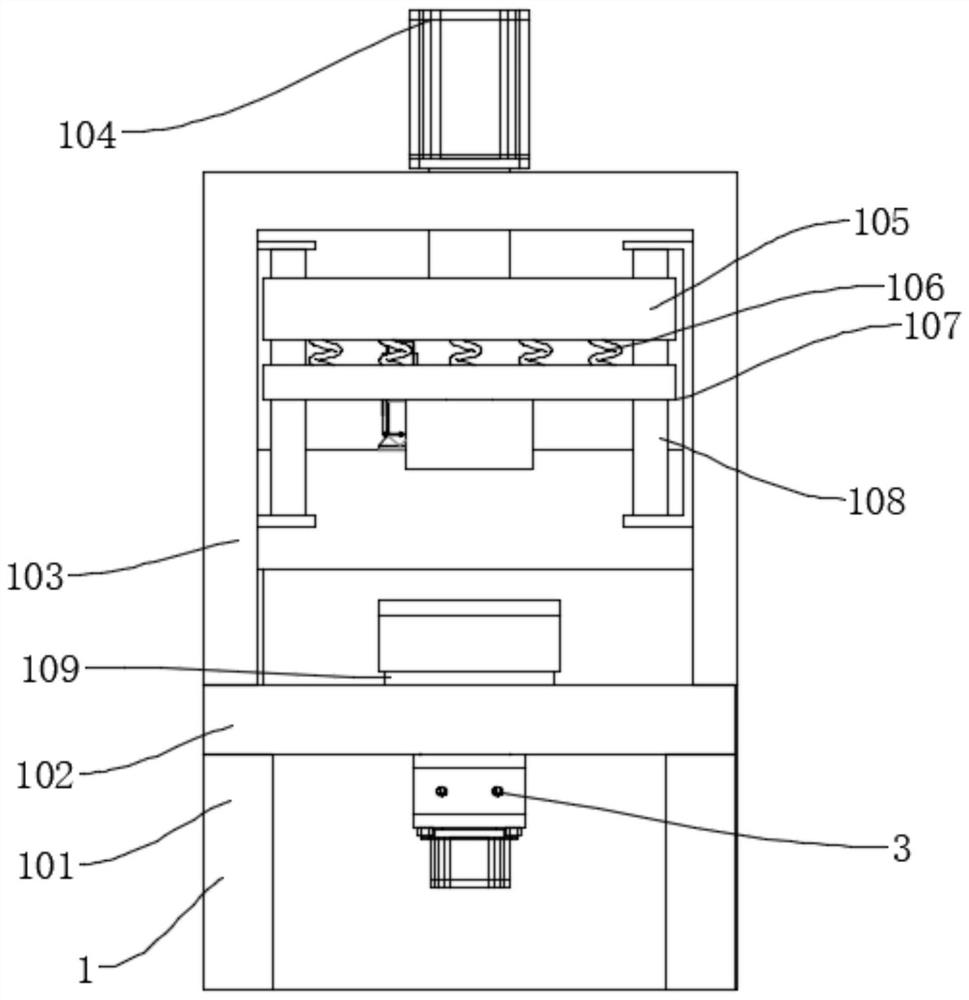

[0034] Such as Figure 1-7As shown, a running wheel forging device for a pole steel mold includes a forging mechanism 1 and a collection box 4. The forging mechanism 1 is mainly composed of a supporting leg 101, a supporting plate 102, a chassis 103, and a workbench 109. The top of the supporting leg 101 passes A support plate 102 is connected by bolts, and the top of the support plate 102 is connected with an organic case 103 and a workbench 109 by bolts. The workbench 109 is located inside the case 103, and the collection box 4 is located behind the support legs 101. It also includes a cooling mechanism 2 and a molding die 3. The mold 3 includes a rotating shaft 303, a rotating mounting plate 304, a first molding die body 305, and a second molding die body 306. The lower end of the rotating shaft 303 passes through the support plate 102 and extends to below the support plate 102, and is connected with a drive assembly. The shaft 303 is connected to the support plate 102 thro...

Embodiment 2

[0037] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the drive assembly includes a drive motor 301 and a worm gear box 31, the drive motor 301 is connected to the bottom of the support plate 102 by bolts, and the output end of the drive motor 301 is connected to the worm gear box The worm of 31 is connected by a coupling, and the turbine of worm gear box 31 is connected to the lower end of rotating shaft 303 through a key, so that the worm gear and worm inside the worm gear box 31 can be driven to rotate by driving motor 301, and then the driving of rotating shaft 303 can be realized. Turn function.

[0038] In the above structure, when in use, first start the external cooling fan 202 and the internal cooling fan 203, then put the material to be forged into the second molding die body 306, and then start the hydraulic cylinder 104, which drives the mounting plate 105 down, The mounting plate 105 squeezes the buffer spring 106, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com