Welding system and welding process of air pipe

An air duct and welding technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of mold preparation and assembly, and achieve the effects of weight reduction, prevention of condensation on the pipe wall, and low ventilation noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with specific implementation methods:

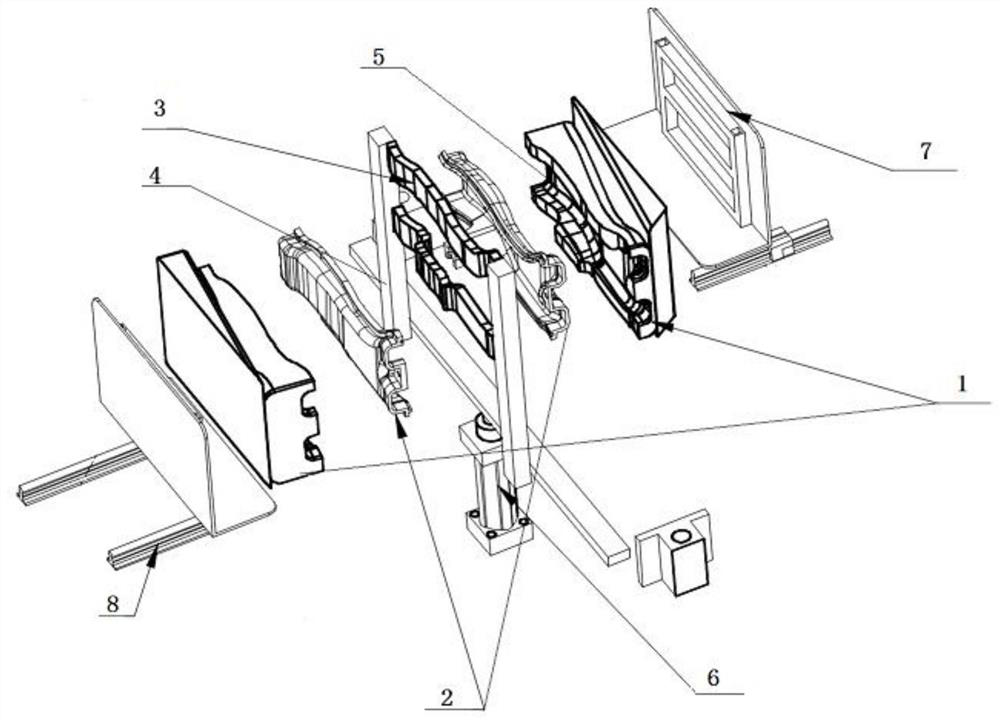

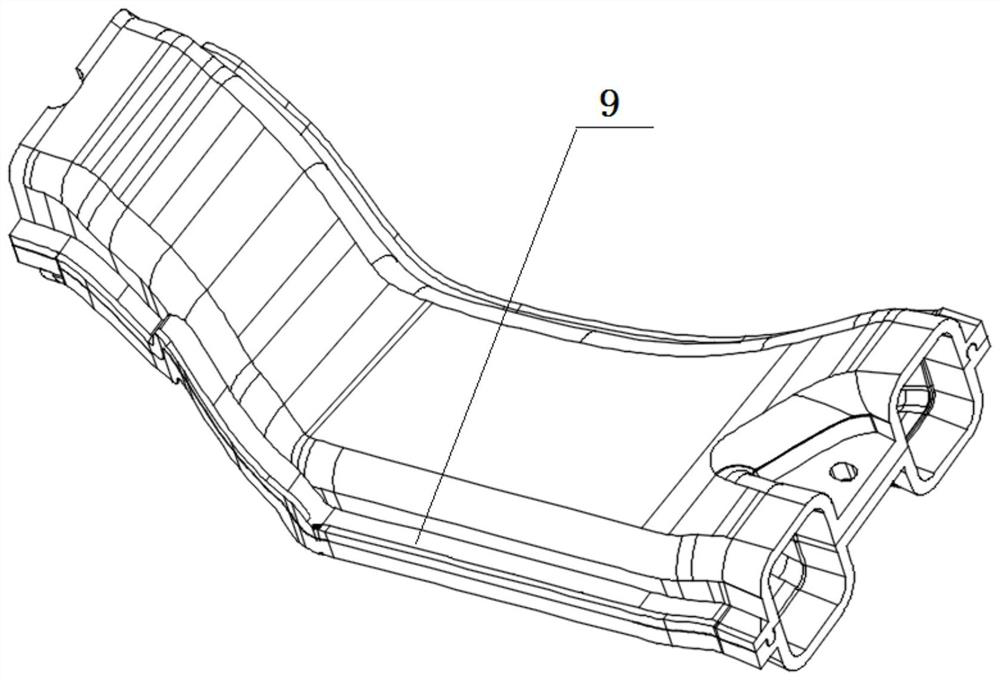

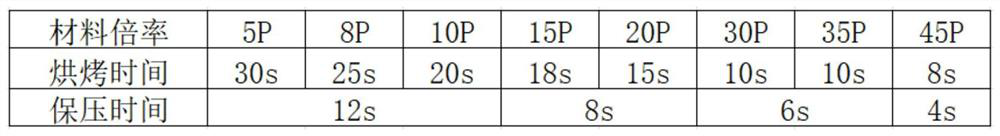

[0028] like Figure 1-5 As shown, the present invention provides an air duct welding system, including welding equipment and a control system. The welding equipment includes two positioning jigs 1 and a heating device that are relatively slidingly arranged, and the opposite surfaces of the two positioning jigs 1 are set There is a positioning cavity 5 for accommodating the half-air duct 2; the heating device includes a movable heating plate 3 for baking and heating the half-air duct 2 in the positioning cavity 5; the control system includes a clamp for controlling the relative sliding of the two positioning fixtures 1 device, a lifting device that controls the heating plate 3 to move up and down between the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com