Tire pressing assembly machine

A technology of tires and racks, which is applied in the field of tire pressing and assembly machines, can solve the problems of shortening production time, slow production speed, and long time consumption, and achieve the effects of shortening production time, reducing waste, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

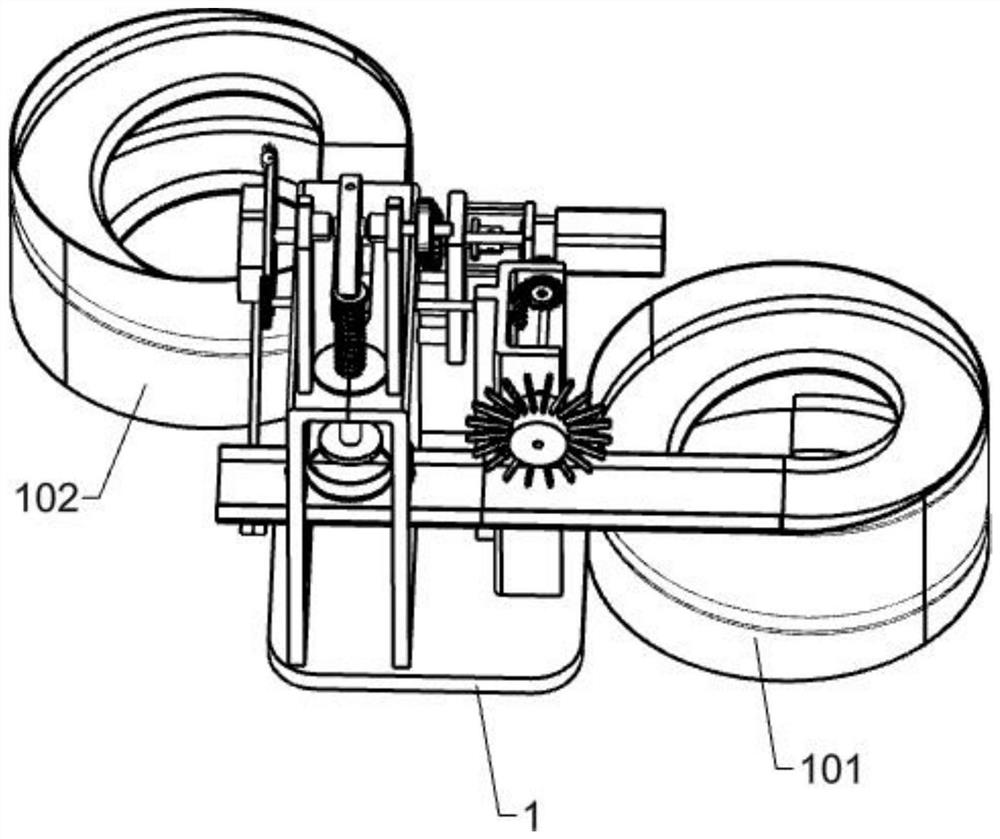

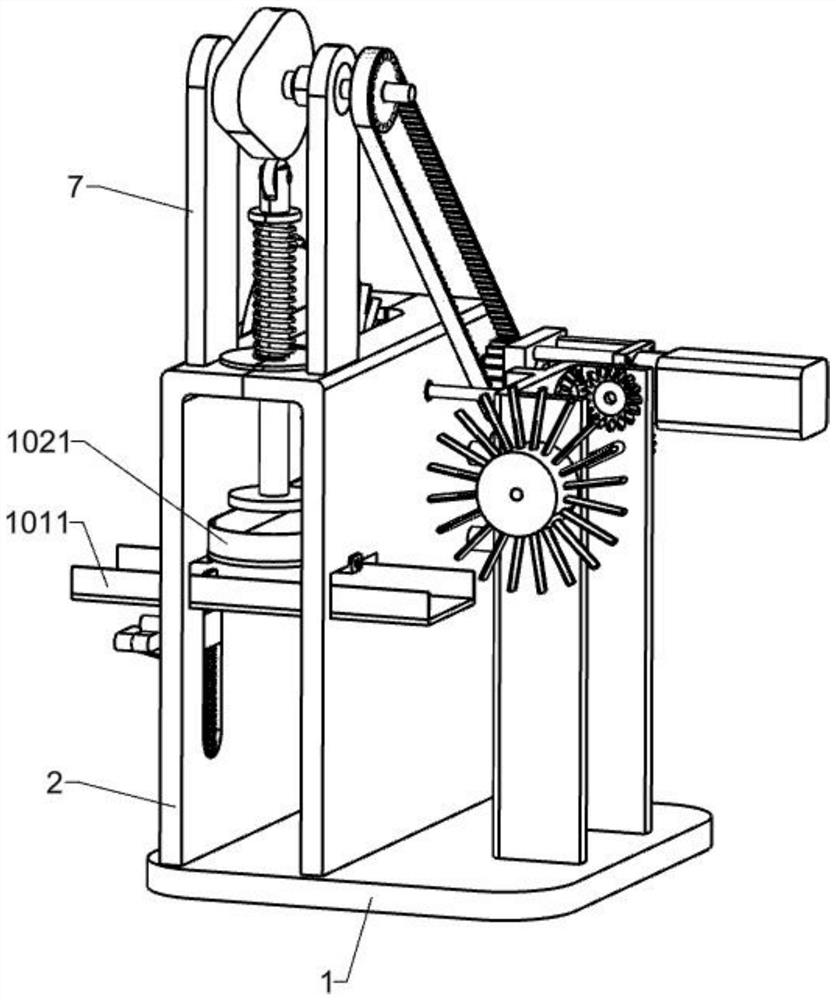

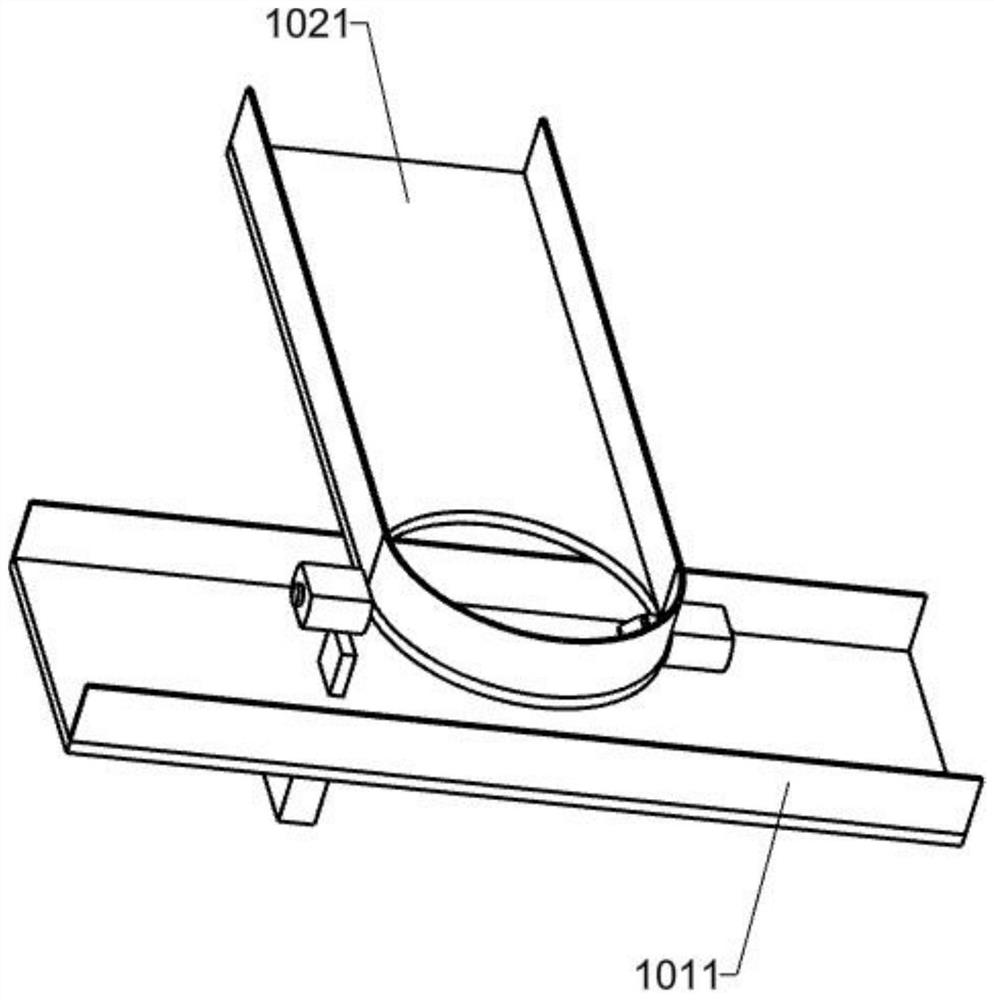

[0027] A tire press assembly machine, such as Figure 1-5 , Figure 7 As shown, it includes base (1), vibration plate one (101), vibration plate two (102), transmission plate one (1011), transmission plate two (1021), frame (2), installation plate one (3) , motor (4), shaft one (5), timing pulley one (6), mounting plate two (7), shaft two (8), timing pulley two (9), timing belt (901), cam One (10), pressure bar (11), spring one (1101) and pressure pad (12), base (1) top is fixedly installed with frame (2), and the top of frame (2) both sides is connected and fixedly installed with transmission Plate one (1011), the left end of vibration plate one (101) is fixedly connected with the right end of transmission plate one (1011), and transmission plate two (1021) is fixedly installed on the frame (2) near the side of transmission plate two (1021), The second transmission plate (1021) is perpendicular to the first transmission plate (1011), the rear end of the vibration plate two ...

Embodiment 2

[0030] On the basis of Example 1, such as Image 6 As shown, the locking mechanism (a) includes a casing (a01), a thimble (a02), a spring two (a03) and an inclined block (a04). In the groove, the thimble (a02) is slidably connected in the shell (a01), and the inside end of the thimble (a02) is fixedly connected with a slanting block (a04), and the second spring (a03) is sleeved on the shell (a01).

[0031] The setting of the locking mechanism (a) is to ensure that the tire will not fall directly when it is sent to the designated position, which will affect the normal operation of the device. When the tire is sent to the designated position, the inclined block in the locking mechanism (a) will (a04) will hold the tire to prevent the tire from falling before pressing down. When the pressure rod (11) and the pressure pad (12) are pressed down, it will squeeze the inclined block (a04) to move outward, and drive the thimble (a02) ) to move outward, and after the tire is successful...

Embodiment 3

[0033] On the basis of Example 2, such as Image 6 , Figure 9 , Figure 10As shown, it also includes support two (13), shaft three (14), toothless tooth disc (15), shaft four (16), spur gear one (17), pulley one (18) and soft rubber Rod one (181), bracket two (13) are fixedly installed on the frame (2) near the right side of the motor (4), the right end of the shaft rod three (14) is fixedly connected with the shaft rod one (5) left end, and the shaft rod three (5) left end is fixedly connected. The left end of (14) is fixedly installed with tooth-missing chainring (15), shaft four (16) is rotatably connected in the frame (2), shaft four (16) is positioned at the back of mounting plate two (7), shaft Four (16) are fixedly equipped with a spur gear one (17) near the left end of the tooth-missing chainring (15), and the spur gear one (17) meshes with the tooth-missing chainring (15). Pulley one (18), a plurality of soft rubber sticks one (181) are distributed in array on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com