Bag arranging mechanism for bag making system

A bag management and manipulator technology, applied in paper product packaging, packaging automatic control, packaging and other directions, can solve the problems of packaging bag deflection or even overturning, affecting work efficiency, and subsequent process effects, saving time and manpower, and achieving reliable and effective structure. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

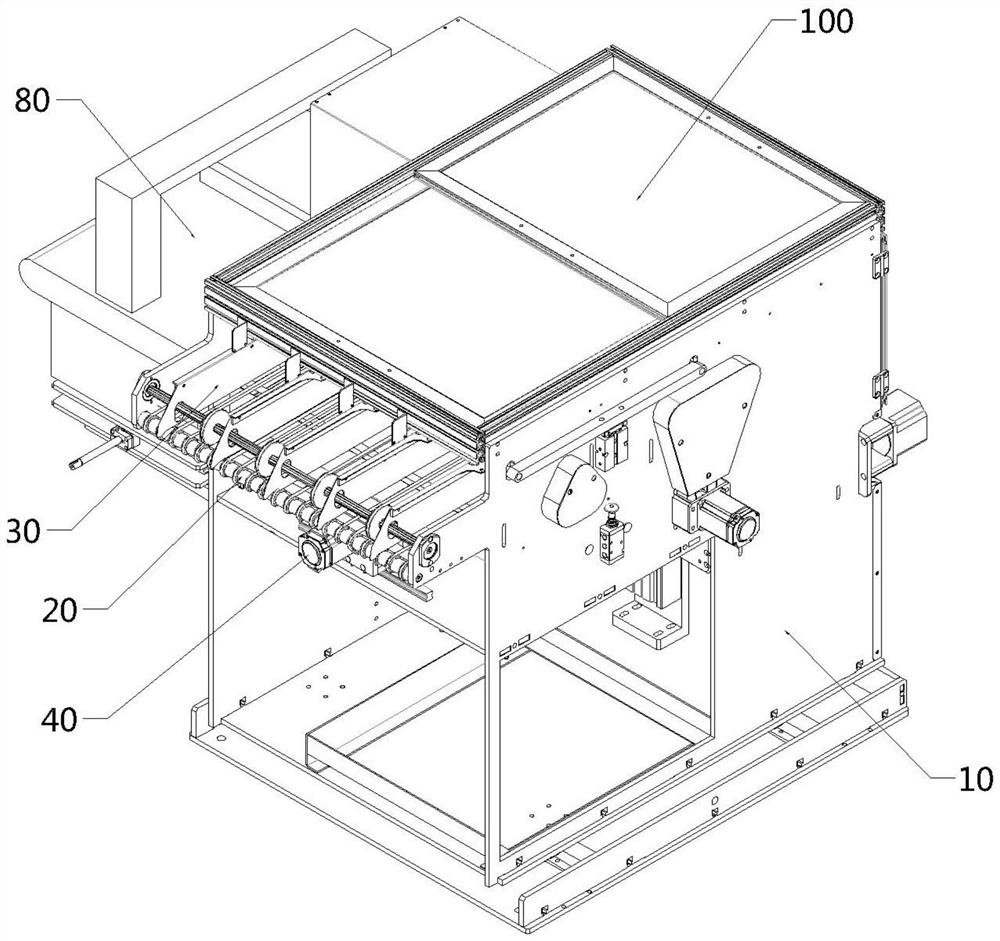

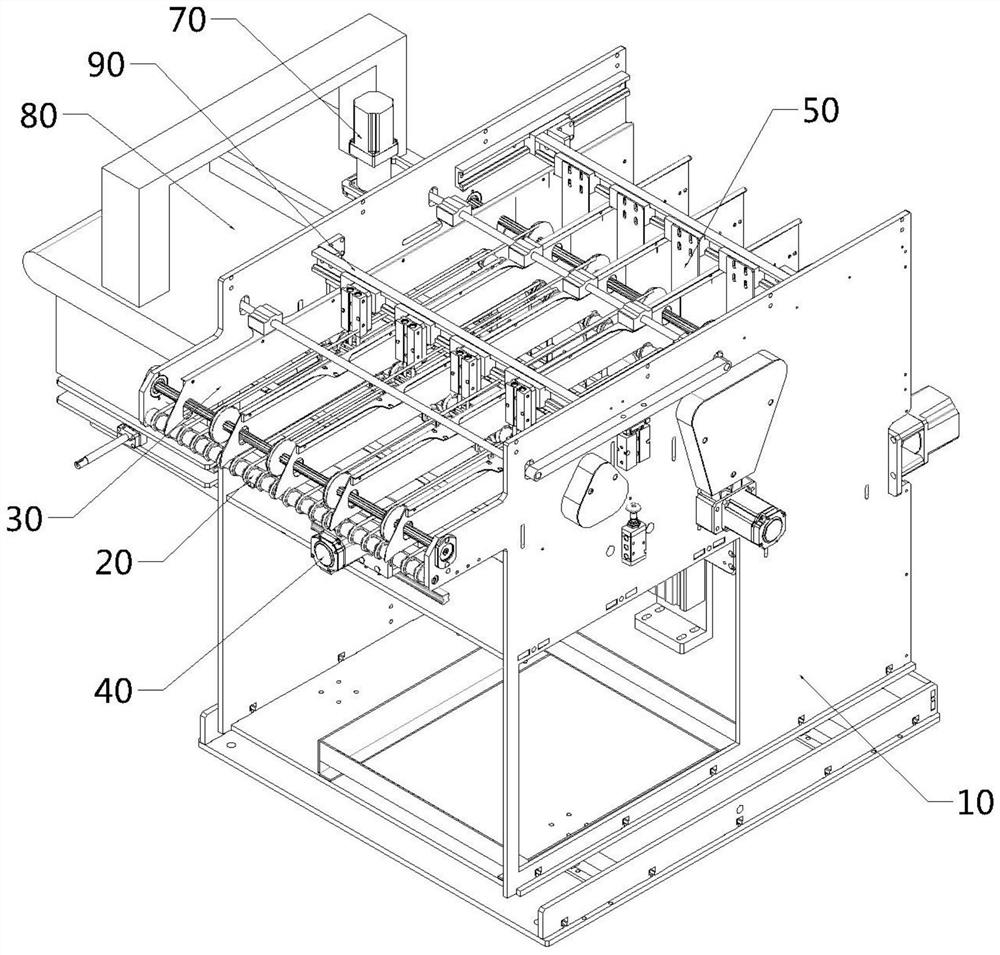

[0069] Embodiment one: if figure 1 - As shown in 4, a bag sorting mechanism for a bag making system, including a bracket assembly 10, on which a first conveying component 20, a partition component 30, a front bag sorting component 40, and a rear bag sorting component 50 are installed And the second transport assembly 60.

[0070] combine Figure 5-6 As shown, the bracket assembly 10 includes an upper base plate 10 and side plates 12 on the left and right sides. A certain number of optical axes 13 are provided between the two side plates 12 for support, and an intermediate partition plate 14 is also provided between the side plates 12 .

[0071] combine Figure 7-9 As shown, the first conveying assembly 20 includes two left-right first conveying rollers 21 located at the front and middle of the side plate 12, and rotating shafts 22 are arranged above the first conveying rollers 21, and the equidistant distances on the first conveying rollers 21 are uniform. A certain number ...

Embodiment 2

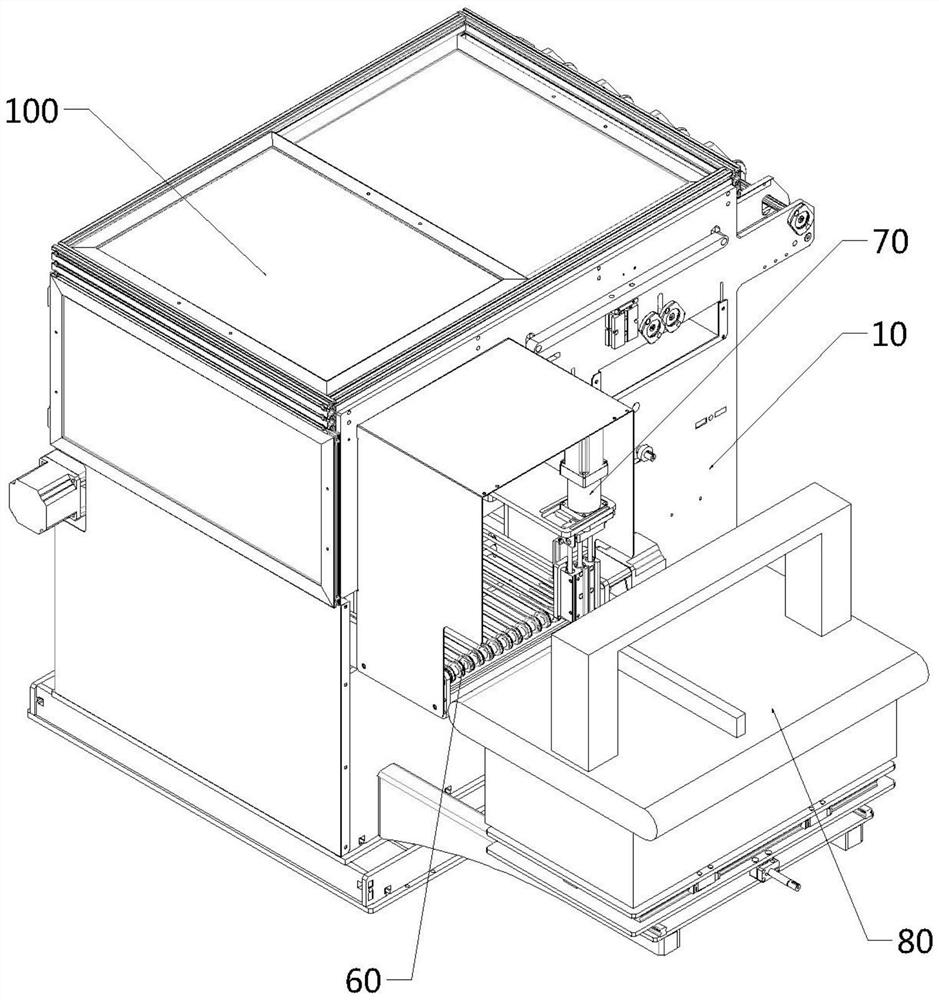

[0077] Embodiment 2: Combination Figure 18-20 As shown, on the basis of Embodiment 1, a reversing manipulator 70 is provided at the conveying end of the second conveying assembly 60, and the reversing manipulator 70 includes a rotating motor 71 fixed on the side plate 12, and a reversing motor 71 is provided below the rotating motor 71. Drag material riser 72, reversing drag material riser 72 both sides are respectively provided with first lift cylinder 73 and second lift cylinder 74, the movable end of first lift cylinder 73 is connected with rotary motor 71 movable end, the second lift cylinder 74 The movable end is provided with a clamping block 75, and the reversing dragging vertical plate 72 below the clamping block 75 is fixed with dragging rods 76 distributed horizontally and equidistantly. The round belt limit ring 62.1. Wherein, the reversing manipulator 70 is also provided with a proximity sensor bracket 77 .

Embodiment 3

[0078] Example Three: Combining Figure 3-4 and Figure 21-22 As shown, on the basis of the second embodiment, a strapping machine assembly 80 is provided outside the reversing manipulator 70, and the strapping machine assembly 80 includes a strapping machine 81, and the strapping machine 81 is connected to the side plate 12 through the bed connecting plate 82 at the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com