Refrigeration compressor shell raw material plate turnover device

A technology of refrigeration compressors and raw materials, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve problems such as defects in welds, and achieve the effect of improving protection, stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

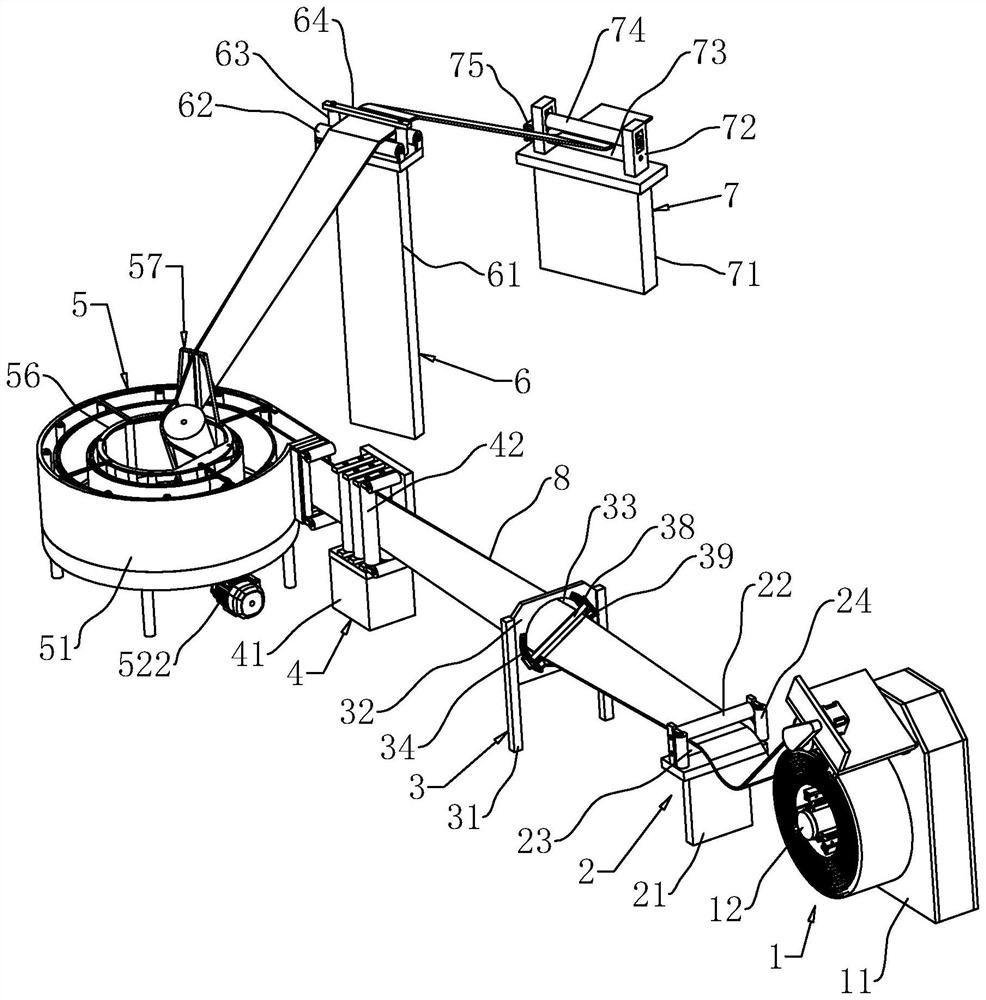

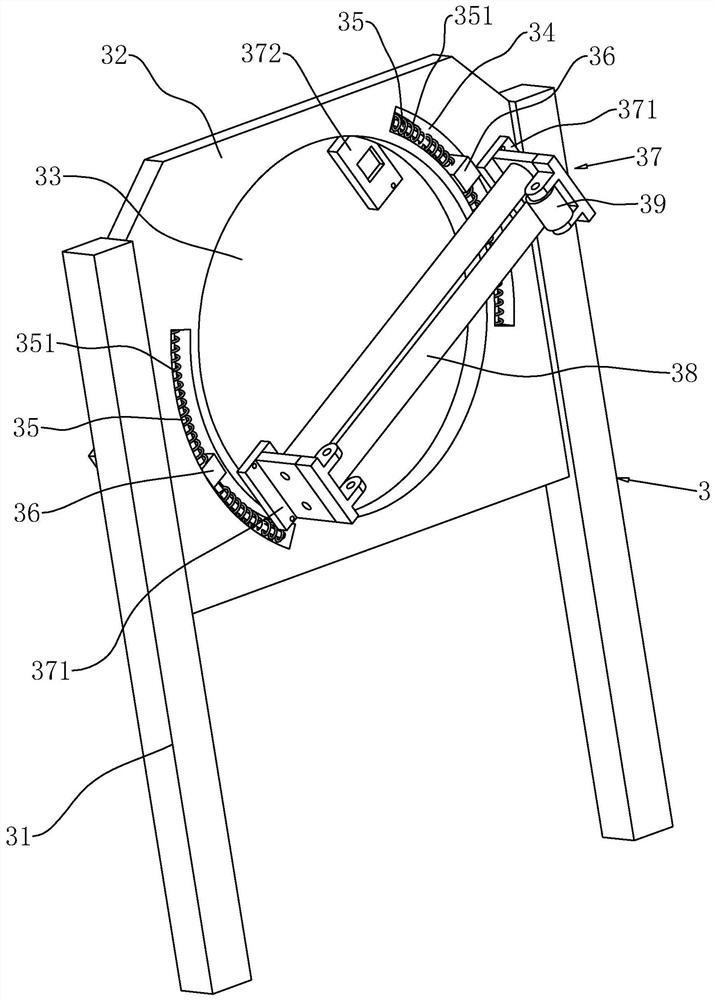

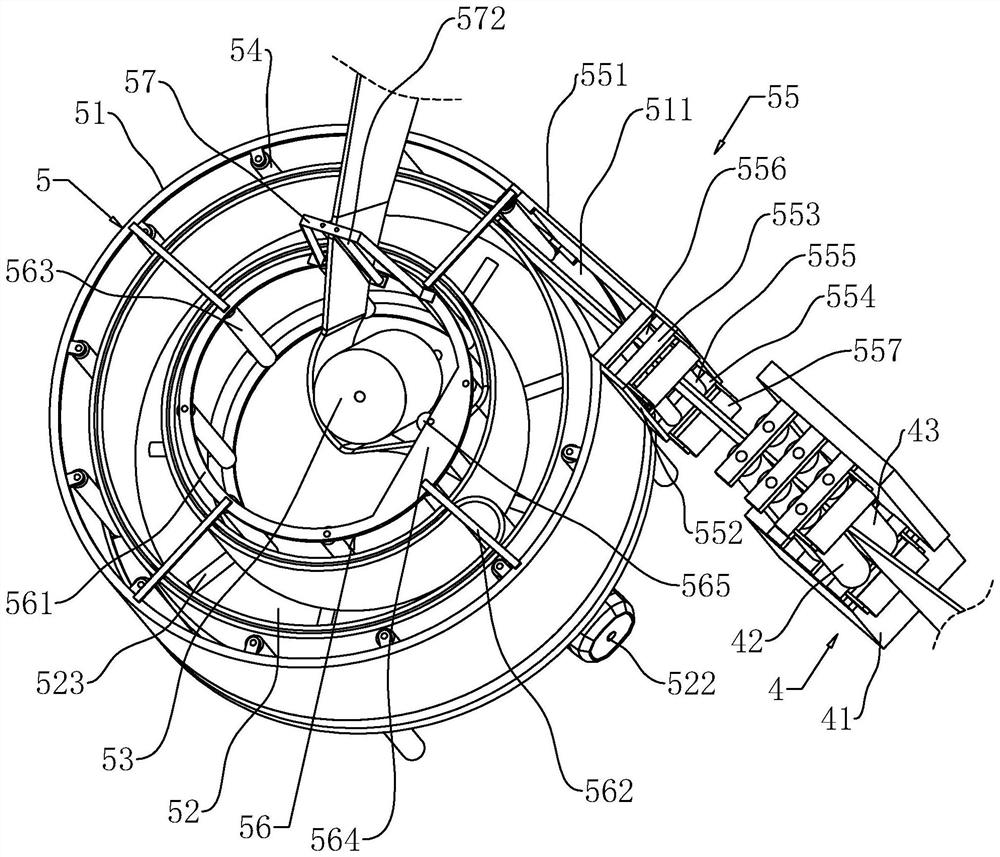

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a device for turning over a raw material plate of a refrigeration compressor shell.

[0038] refer to figure 1 , a device for turning over a raw material plate of a refrigeration compressor shell, comprising a discharge mechanism 1 and a traction mechanism 7, a first guide mechanism 2, a deflection mechanism 3, and a second guide mechanism are sequentially arranged between the discharge mechanism 1 and the traction mechanism 7 4 and turning mechanism 5 and the third guiding mechanism 6. The steel strip is cut into two strips by the cutting mechanism, and wound into two strip coils respectively. Unwinding mechanism 1 is used for placing strip coil. The pulling mechanism 7 is used to pull one end of the steel strip 8 to the roll forming place to roll and weld the steel strip 8 . The first guide mechanism 2 is used to draw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com