Cloth processing device for textile cloth printing and dyeing

A processing device and textile fabric technology, which is applied in the cutting of textile materials, textile and papermaking, fabric surface trimming, etc., can solve the problems of inability to realize vacuuming and edge material winding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

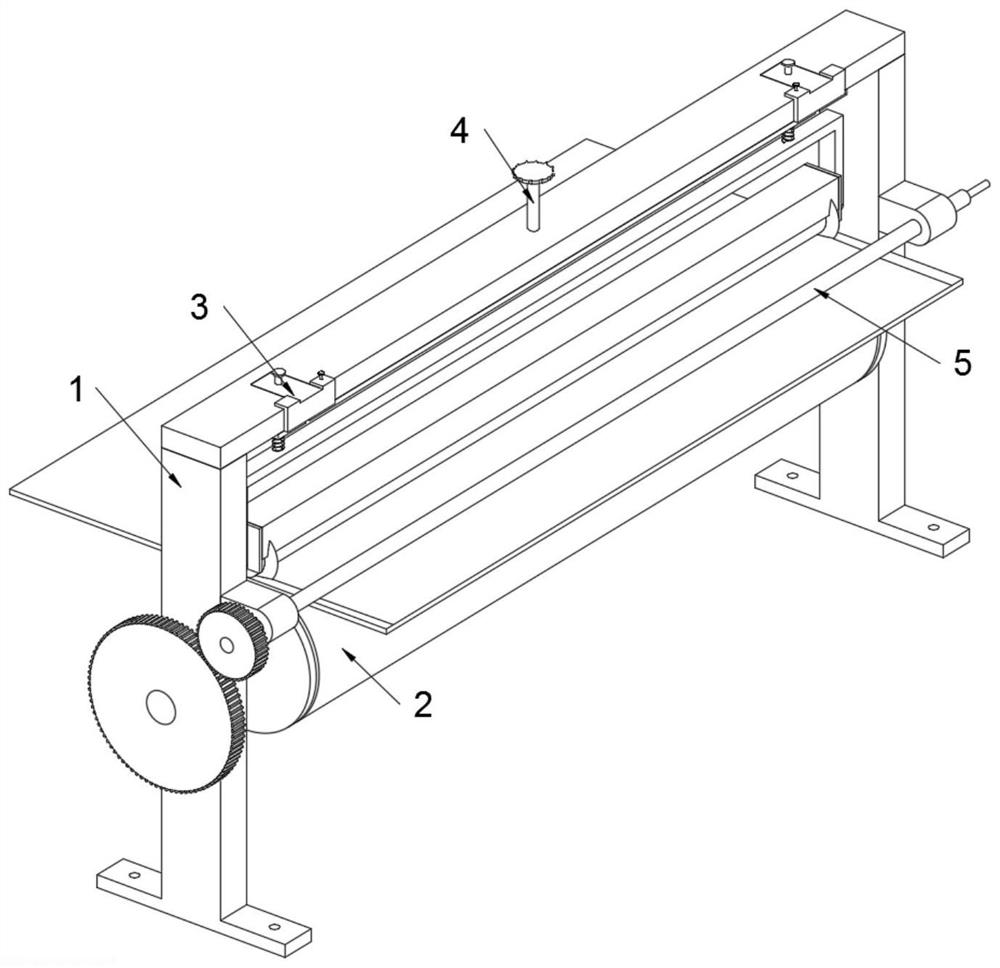

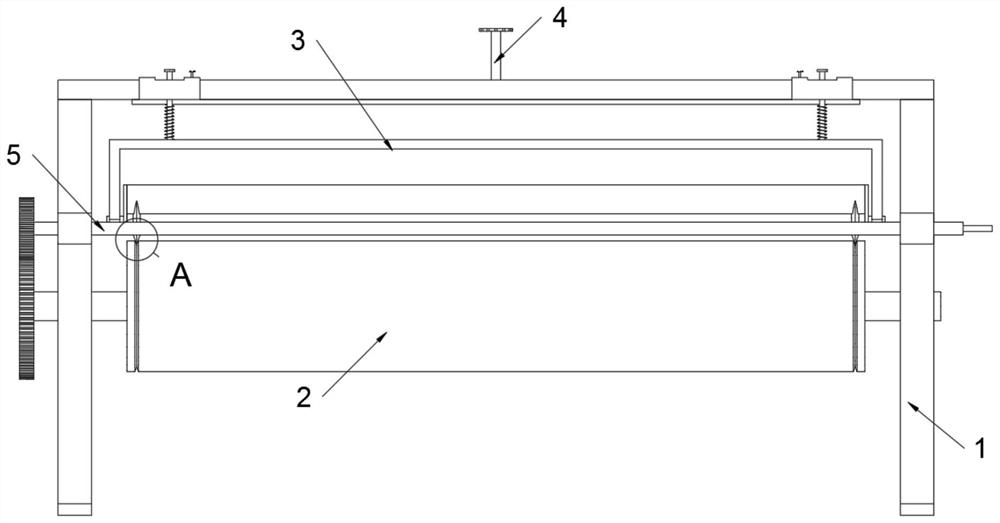

[0035] as attached figure 1 to attach Figure 9 Shown:

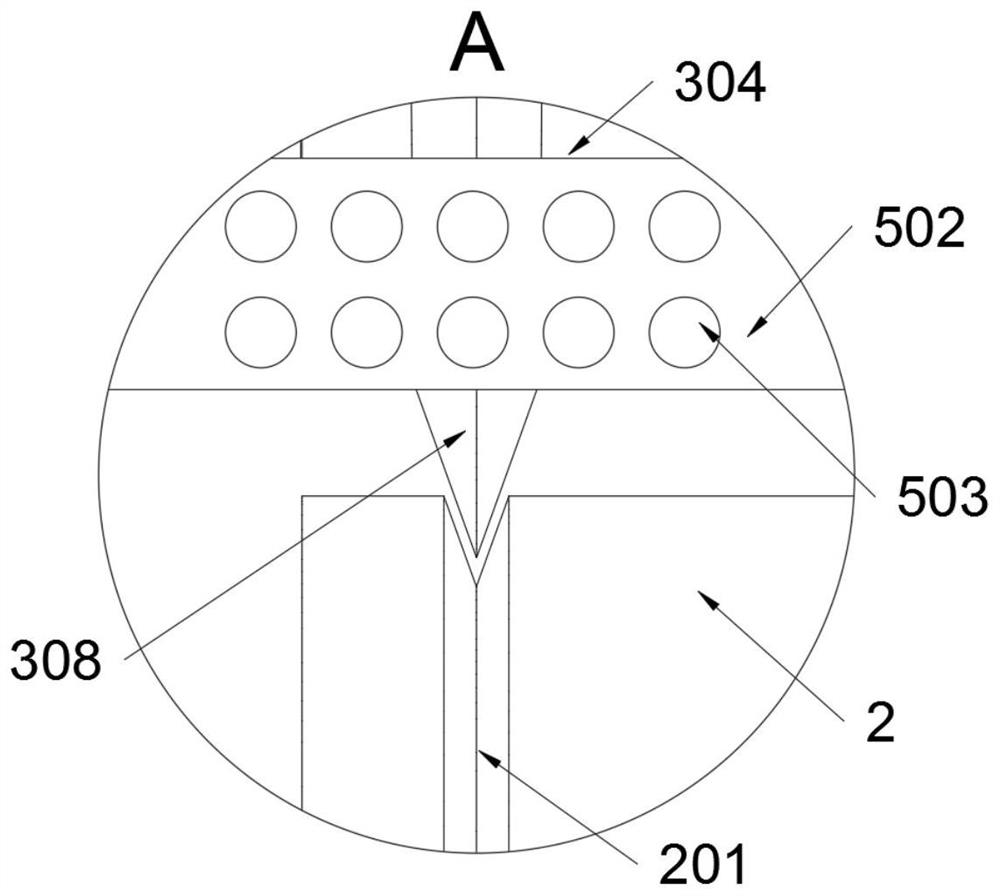

[0036] The invention provides a cloth processing device for textile printing and dyeing, which comprises a frame body 1; a conveying roller 2 is rotatably connected to the frame body 1, and a processing structure 3 is installed on the frame body 1, and an adjustment structure is also installed on the frame body 1 4; The dust suction structure 5 is installed on the frame body 1; refer to as Figure 4The conveying roller 2 includes a gear A202, and a gear A202 is installed on the rotating shaft of the conveying roller 2; the dust suction structure 5 also includes a gear B504, and the gear B504 is installed on the dust suction pipe 502, and the gear B504 meshes with the gear A202, so that The strips of cloth cut under the suction of the suction holes 503 can be adsorbed on the suction pipe 502, and when the conveying roller 2 drives the suction pipe 502 to rotate, the strips of cloth can be rolled up.

[0037] Reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com