Permeable pavement construction process

A construction technology and technology of seepage bricks, which are applied in the directions of roads, roads, pavement details, etc., can solve problems such as easy accumulation of water on the road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

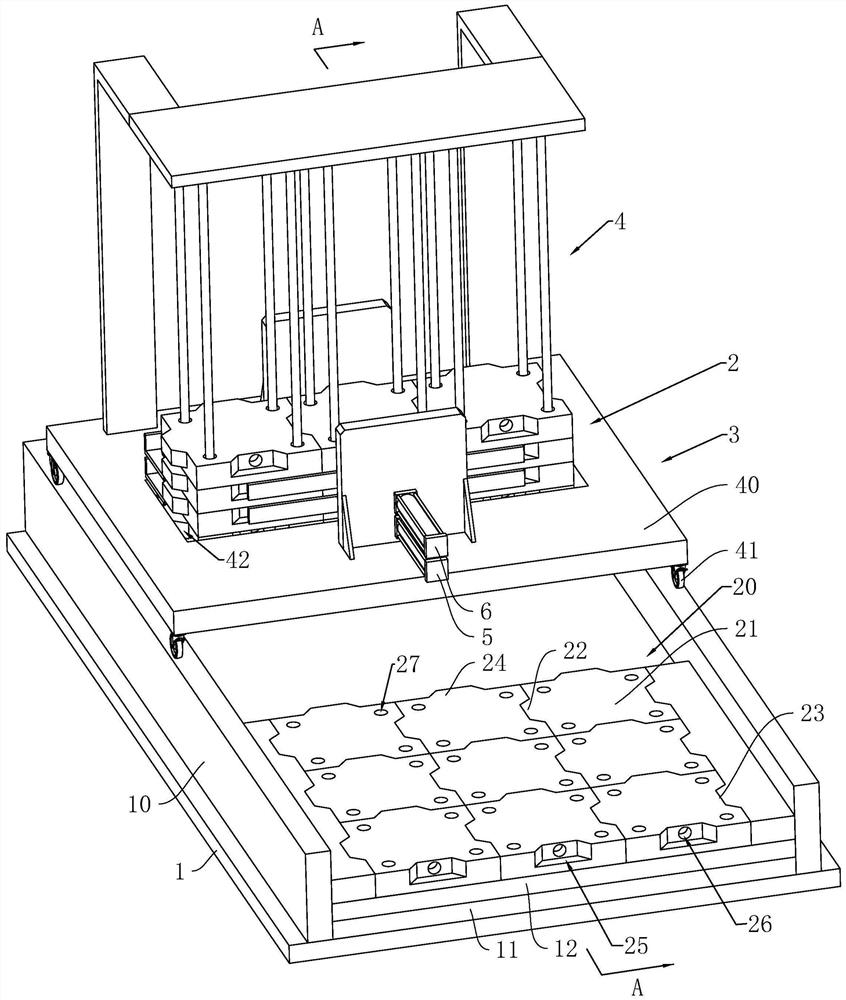

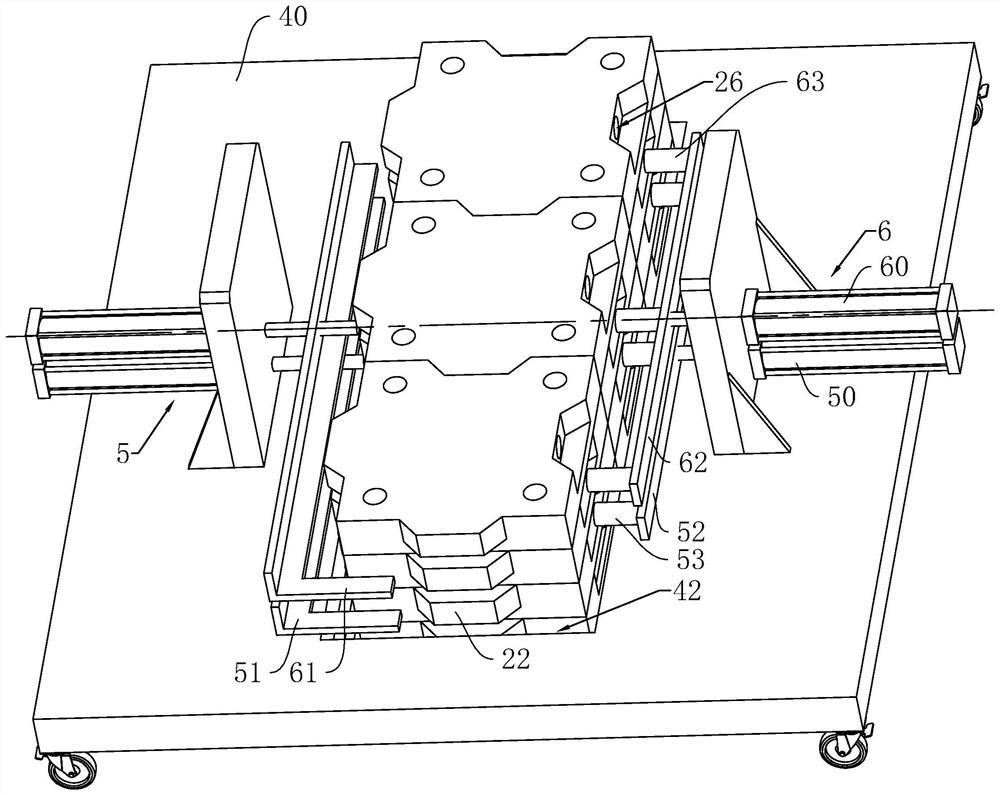

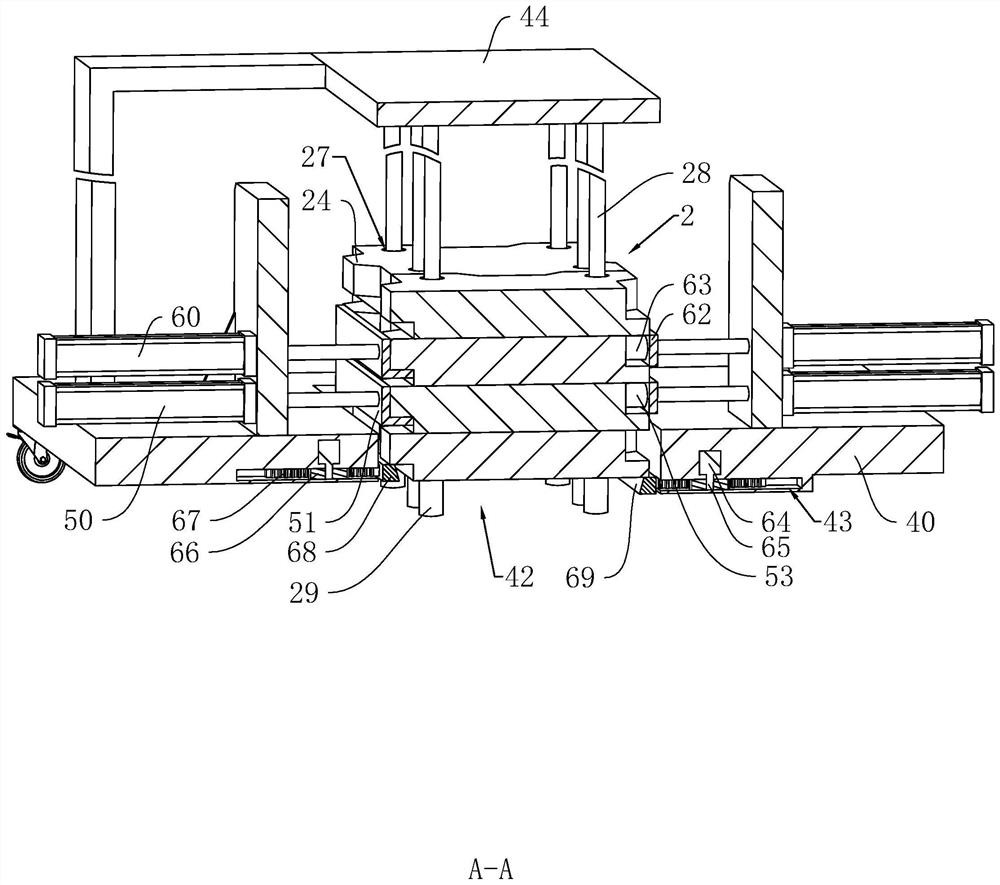

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a permeable pavement construction process.

[0042] refer to figure 1 , a permeable pavement construction process, comprising the following specific steps:

[0043] S1. Select the site, excavate the foundation pit 1, clean the soil in the foundation pit 1, and use a road roller to compact and flatten the foundation pit 1, and then pave road shoulders 10 on both sides of the foundation pit 1, and between adjacent road shoulders 10 Fill the gap with cement to increase the installation stability of the road shoulder 10 in the foundation pit 1;

[0044] S2, spreading the graded crushed stone layer 11 on the soil layer of the foundation pit 1 and rolling and leveling;

[0045]S3, spreading the coarse sand layer 12 on the graded crushed stone layer 11 and rolling and leveling;

[0046] S4, using the brick laying device 3 to sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com