Paste strip grouting combined filling mining method for coal mine goaf

A mining method and paste filling technology, which is applied to filling materials, mining equipment, earth square drilling, etc., can solve the problems of low output and poor recovery efficiency of filling working faces, so as to alleviate the contradiction between mining and filling, reduce the loss of coal pillars, The effect of improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] This embodiment relates to a coal mine goaf paste strip grouting combined filling mining method, including the following steps:

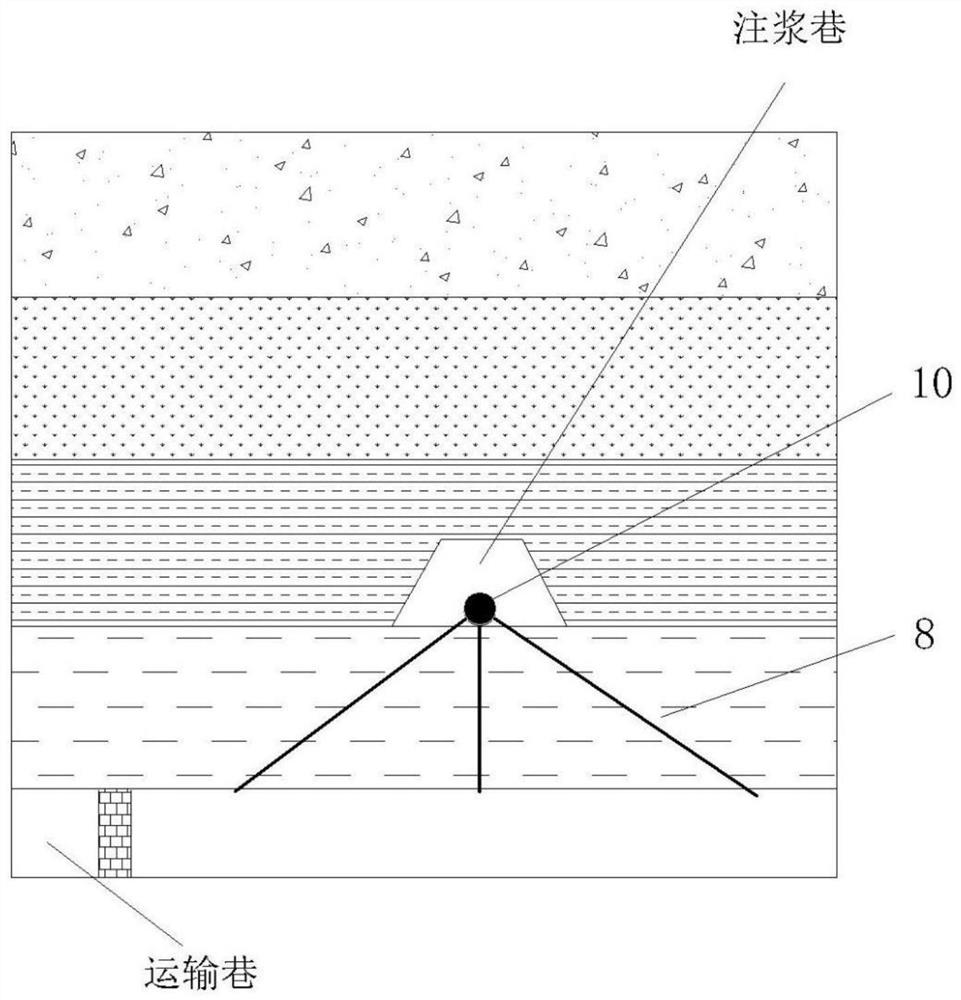

[0029] Step 1, before the mining of the working face, excavate a grouting roadway above the working face in advance;

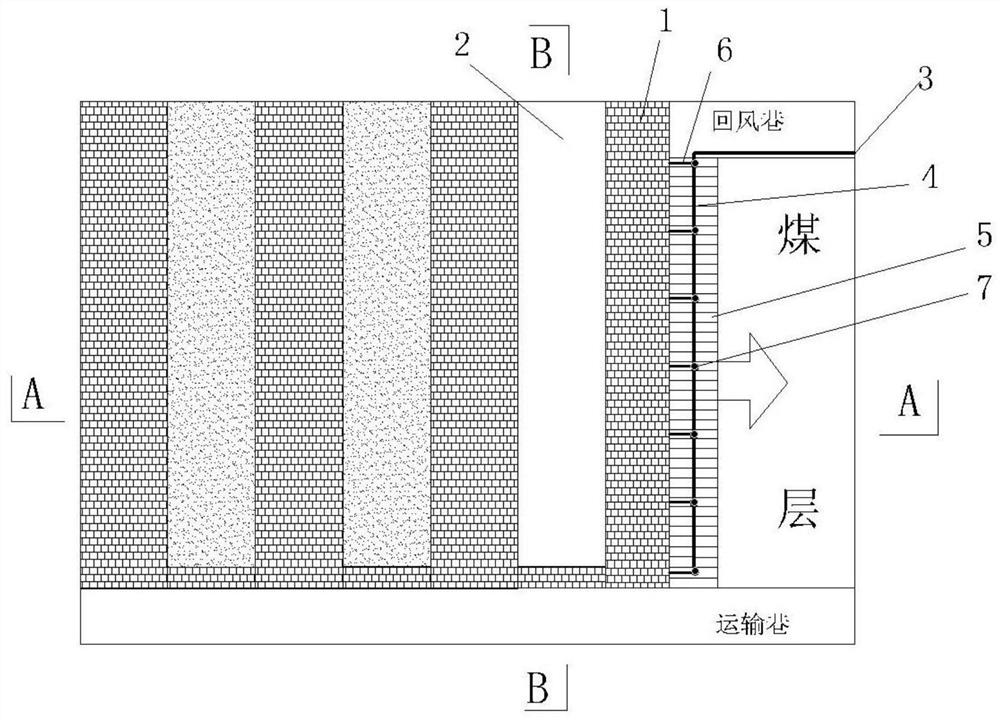

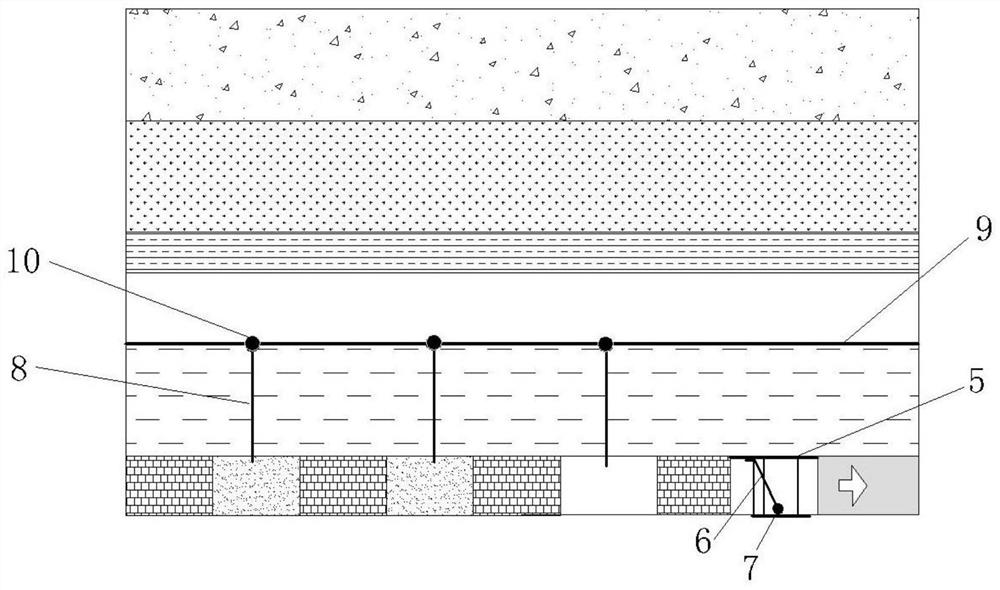

[0030] Step 2, according to the actual coal seam geological conditions of the mine, such as figure 1 , figure 2 , image 3 Shown: Calculate the width of the filling area 1 and the unfilled area 2 in strip filling mining, and design the strip filling mining scheme to ensure that the unfilled area 3 does not collapse directly; the process of strip filling mining scheme design can refer to Calculated by methods disclosed in the prior art.

[0031] Step 3, use the ground surface to establish a paste filling station, and fill the designed filling area 1 with paste through the filling pipeline. The filling pipeline 3 of the main line is made of double-layer wear-resistant metal pipes, which are laid on the bottom plate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com