Rubber spring and its design method

A technology of rubber spring and design method, which is applied in the direction of spring, low internal friction spring, spring/shock absorber, etc., can solve the problem of low installation space, meet the requirements of low installation space, reduce the maximum radial diameter, and simplify adjustment easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

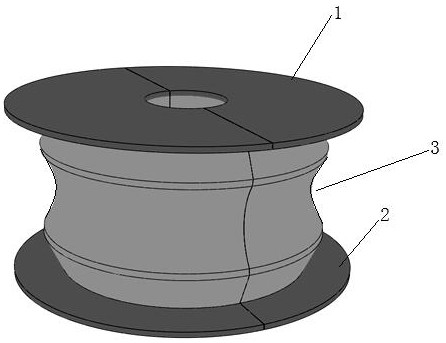

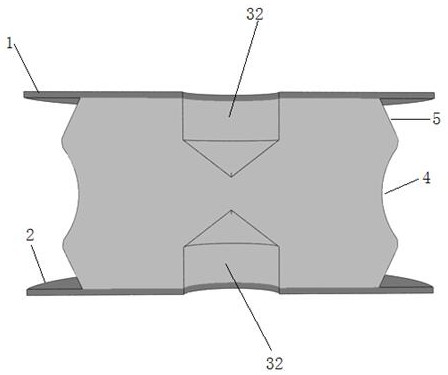

[0036] Combine below Figure 1~4 Embodiments of the present invention are described in detail.

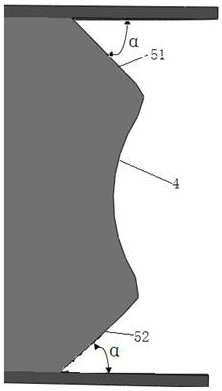

[0037] The rubber spring comprises an upper metal plate 1, a lower metal plate 2 parallel to the upper metal plate 1 and a rubber layer 3 vulcanized between the upper metal plate 1 and the lower metal plate 2, and is characterized in that the circumferential outer profile of the rubber layer 3 31 includes the radial bulge for constraining the rubber layer 3 so that the radial bulge of the rubber layer 3 does not exceed the edge of the upper metal plate 1 and the lower metal plate 2 within the normal load range. 3 Axial rigidity The axial rigidity defines the annular surface 5, and the axial stiffness limiting annular surface 5 is arranged at both ends of the constraining annular surface 4.

[0038] The circumferential outer surface 31 of the rubber layer 3 in the above-mentioned rubber spring includes a constraining surface 4, which is used to constrain the radial bulge of the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com