Design method of valve for unloading double abrasive tanks and reversing sand-water mixture in front-mixing water cutting jet

A water jetting machine, mixing and automatic technology, applied in the direction of abrasive material feeding device, used abrasive processing device, abrasive material, etc., can solve the problem that the water jetting machine cannot cut continuously, and achieve light weight, simple structure, and specifications Full range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

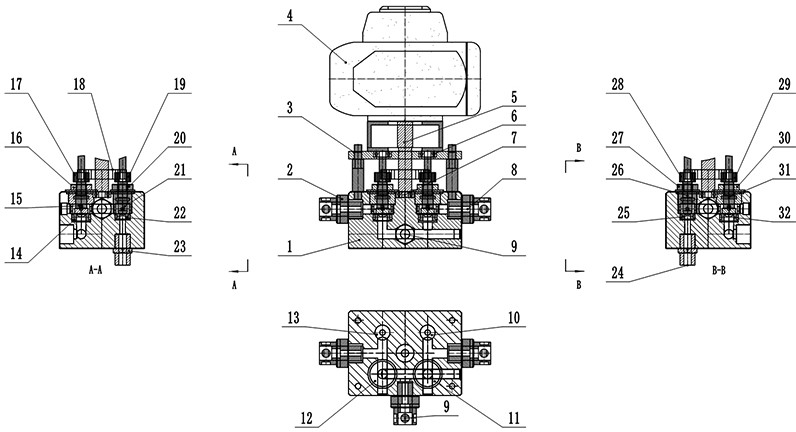

[0016] Double abrasive tank front mixing water cutting machine sand-water mixing automatic unloading reversing valve, including mixed water unloading reversing valve block 1, A abrasive tank liquid inlet joint 2, reversing motor bracket 3, reversing motor 4, motor Rotary shaft 5, spool bearing 6, main shaft deep groove ball bearing 7, B abrasive tank liquid inlet joint 8, mixed water outlet joint 9, B tank unloading hole 10, B tank liquid supply hole 11, A tank liquid supply hole 12. Tank A unloading hole 13, tank A liquid supply valve seat 14, tank A liquid supply opening and closing valve core 15, tank A liquid supply valve core reversing sleeve 16, tank A liquid supply rotating gear 17, motor drive driving gear 18. Tank A sand cleaning unloading rotary gear 19, tank A sand cleaning unloading valve core reversing sleeve 20, tank A sand cleaning unloading valve core 21, tank A sand cleaning unloading valve seat 22, tank A sand cleaning unloading valve seat Loading joint 23, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com