Installing and supporting device for glass magnesium composite air pipe

A composite air duct and support device technology, applied in the direction of pipe brackets, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of cumbersome process, inconvenient air duct installation, and affecting the efficiency of air duct installation, so as to achieve simple operation, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

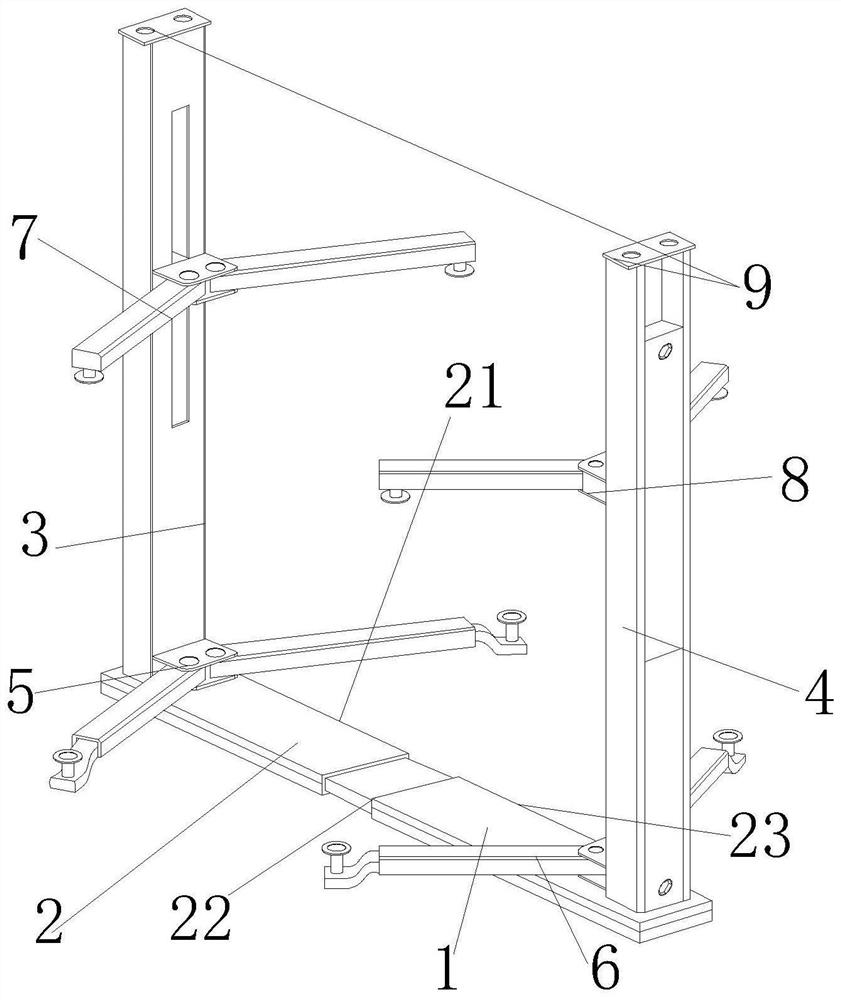

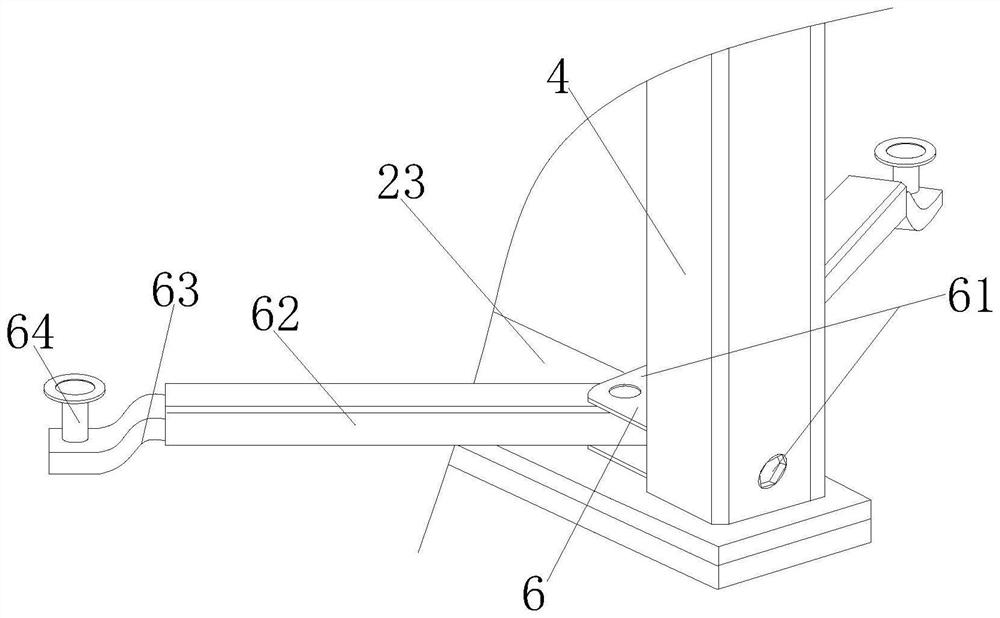

[0031] see figure 1 , a glass-magnesium composite air duct installation and support device of the present invention includes a support body 1, and the support body 1 includes an underframe 2, a left column 3, a right column 4, a left support structure 5, a right support structure 6, and a left clamping structure. Structure 7, right clamping structure 8 and mounting piece 9, left column 3 and right column 4 are fixed vertically on the left and right sides of the top of the bottom frame 2 respectively, left support structure 5 is embedded in the bottom of the right part of left column 3, and the left support The bottom of the structure 5 is connected with the bottom frame 2, the right support structure 6 is embedded in the left bottom of the right column 4, and the bottom of the right support structure 6 is connected with the bottom frame 2, and the left clamping structure 7 is installed on the top side of the left column 3 , the right clamping structure 8 is installed on the in...

Embodiment 2

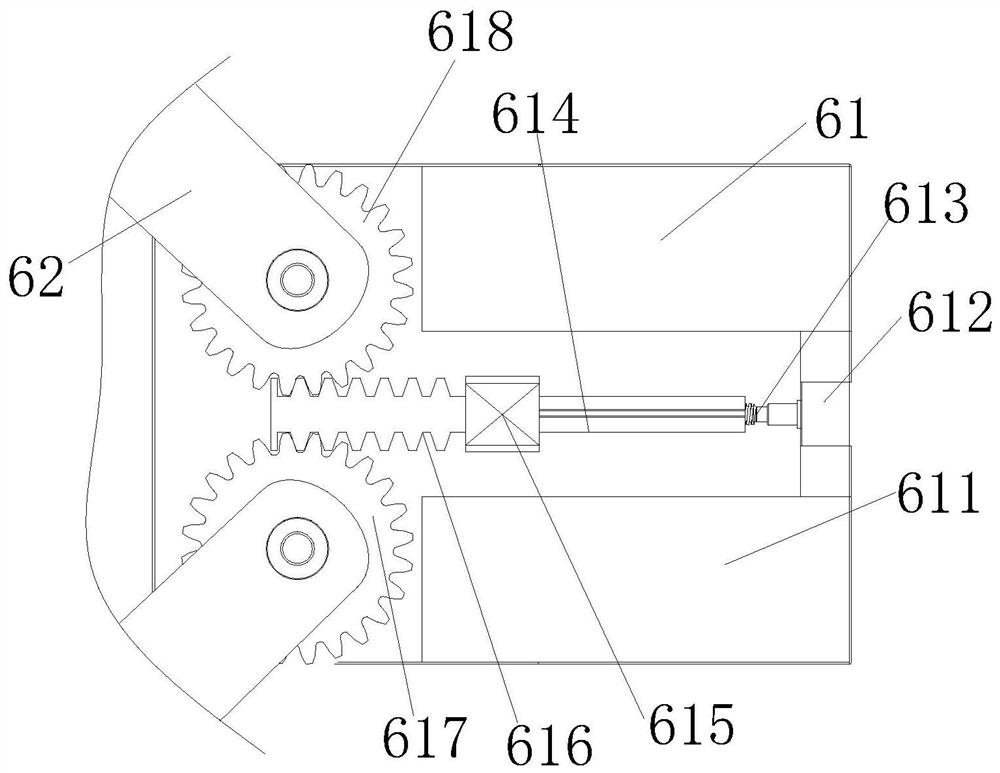

[0037] In the installation and support device for a glass-magnesium composite air duct of the present invention, the left support structure 5 and the right support structure 6 have the same structure size, and the left support structure 5 and the right support structure 6 are arranged symmetrically on the left and right in the middle of the support plate 22, and the rod frame 62 is provided with two, and the two rod frames 62 are arranged symmetrically front and back in the middle of the rotating assembly 61, which is conducive to supporting and fixing the bottom of the air duct. The bumps and the grooves on the top side of the limit block 615 are limited and matched with each other to prevent the internal thread sleeve 614 from rotating inside the limit block 615 and ensure that the internal thread sleeve 614 moves laterally. The left clamping structure 7 and the right clamping structure 8 have the same structure size, and the left clamping structure 7 and the right clamping s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com