Online leakage detection corrugated pipe compensator applied to high-temperature occasions and leakage detection method

A technology of bellows and compensators, which is applied to expansion compensation devices for pipelines, pipe components, pipeline systems, etc., can solve problems such as increasing safety hazards, increasing labor intensity of operation and maintenance personnel, and failing to find bellows compensators in time , to achieve the effect of reducing labor costs and avoiding direct damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

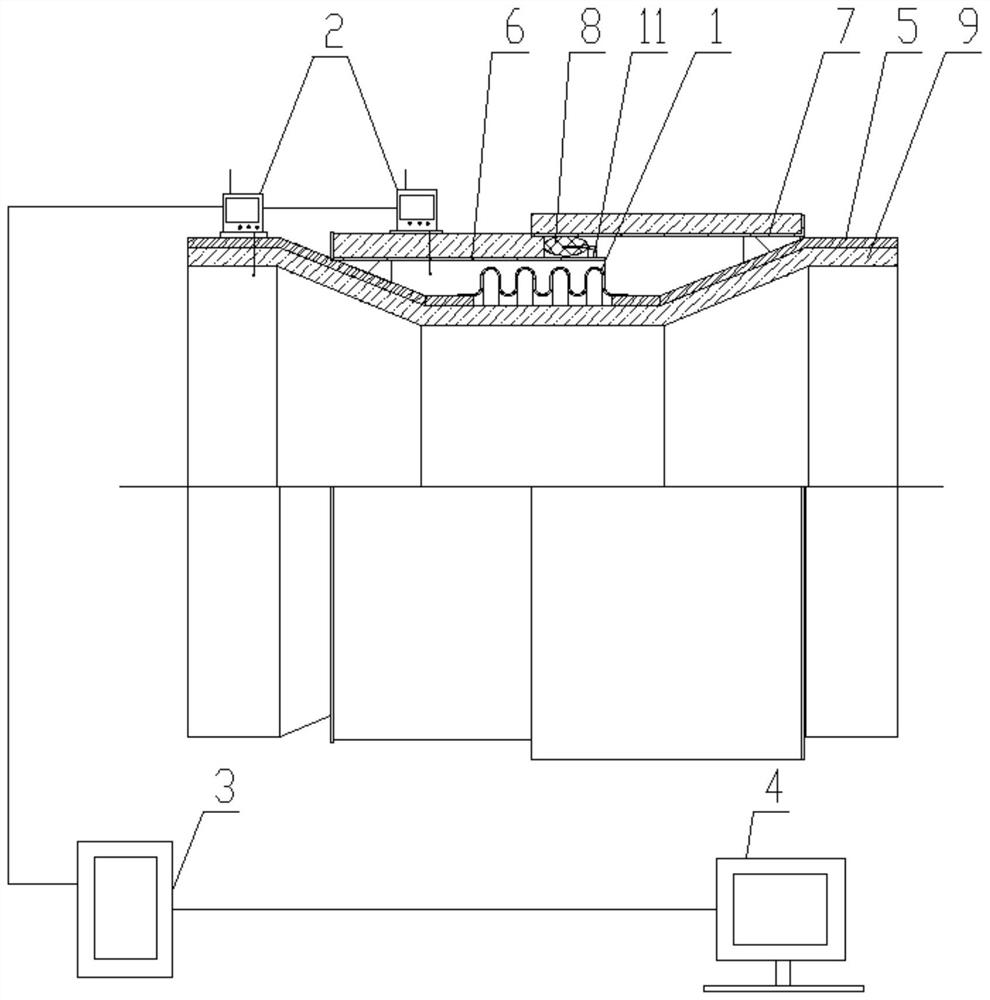

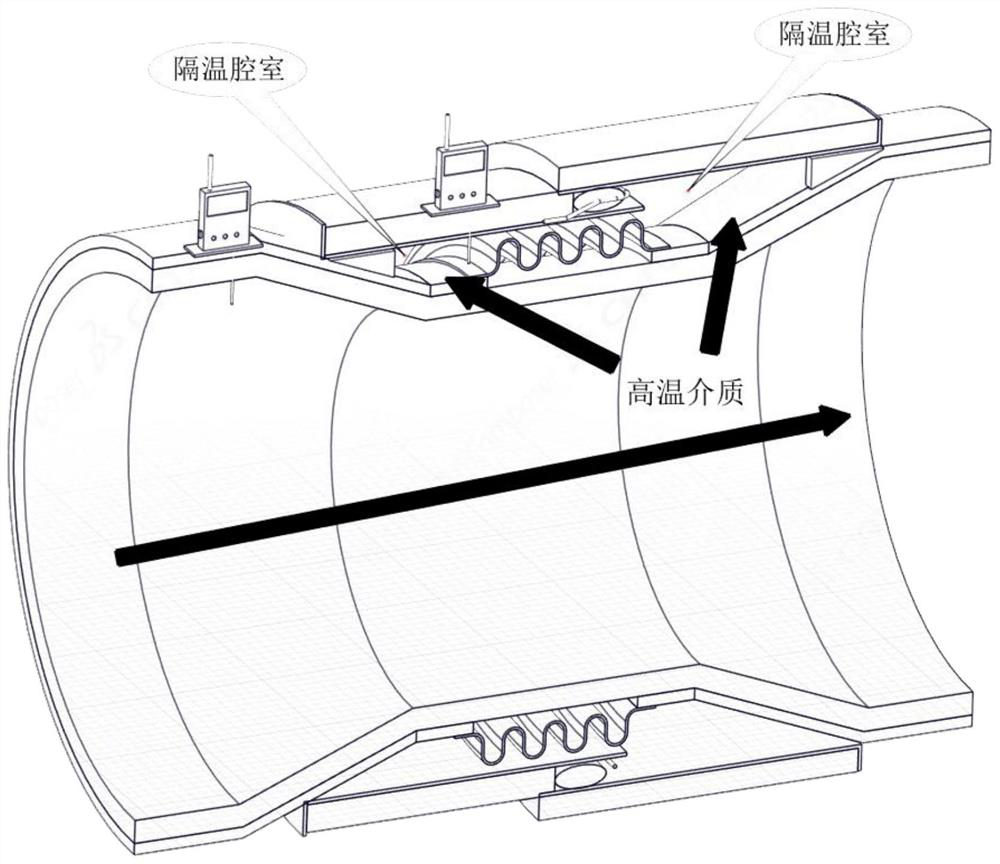

[0023] refer to figure 1 , the present invention provides an on-line leak detection bellows compensator for high temperature occasions, including a bellows 1, an external thermal insulation structure with variable length, two temperature sensors 2, a data processing device 3 and a terminal display device 4, the bellows 1 is connected to the detection pipeline 5, and an external thermal insulation structure is set outside the bellows 1, one end of the external thermal insulation structure is fixedly connected to the detection pipeline 5 on one side of the bellows 1, and the other end of the external thermal insulation structure is connected to the other end of the bellows 1. The detection pipeline 5 on one side is fixedly connected, and the detection pipeline 5, the outer wall of the bellows 1, and the outer heat preservation structure form a circumferential temperature-insulating cavity, and at least one probe of the temperature sensor 2 extends into the temperature-insulating ...

Embodiment 2

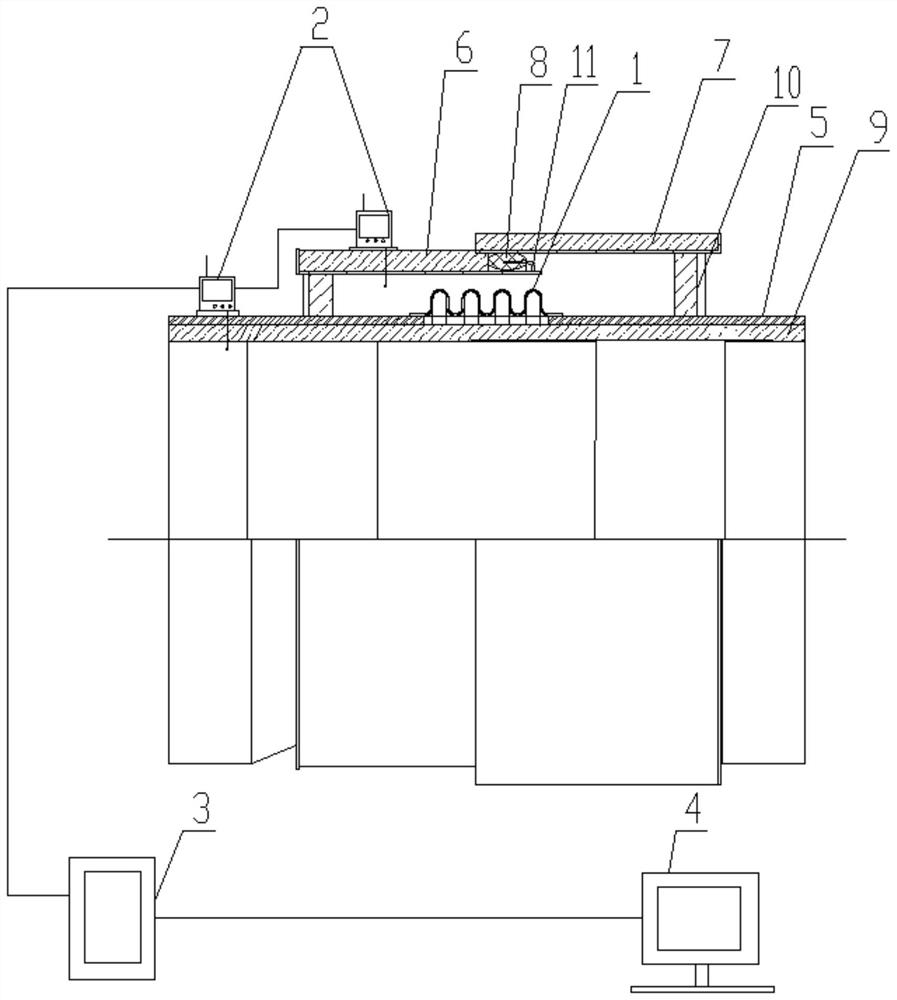

[0036] refer to image 3 , the difference between this embodiment and embodiment 1 is that: the position where the on-line leak detection bellows compensator is installed on the detection pipeline 5 is a straight pipeline, the bellows 1 is connected to the straight pipeline, and the two bellows 1 One end of the external heat preservation structure is connected to the fixed ring 10 on one side of the straight pipeline, and the other end is connected to the fixed ring 10 on the other side of the straight pipeline. The two fixed rings 10. An insulation cotton layer is arranged on the outer side away from the temperature insulation cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com