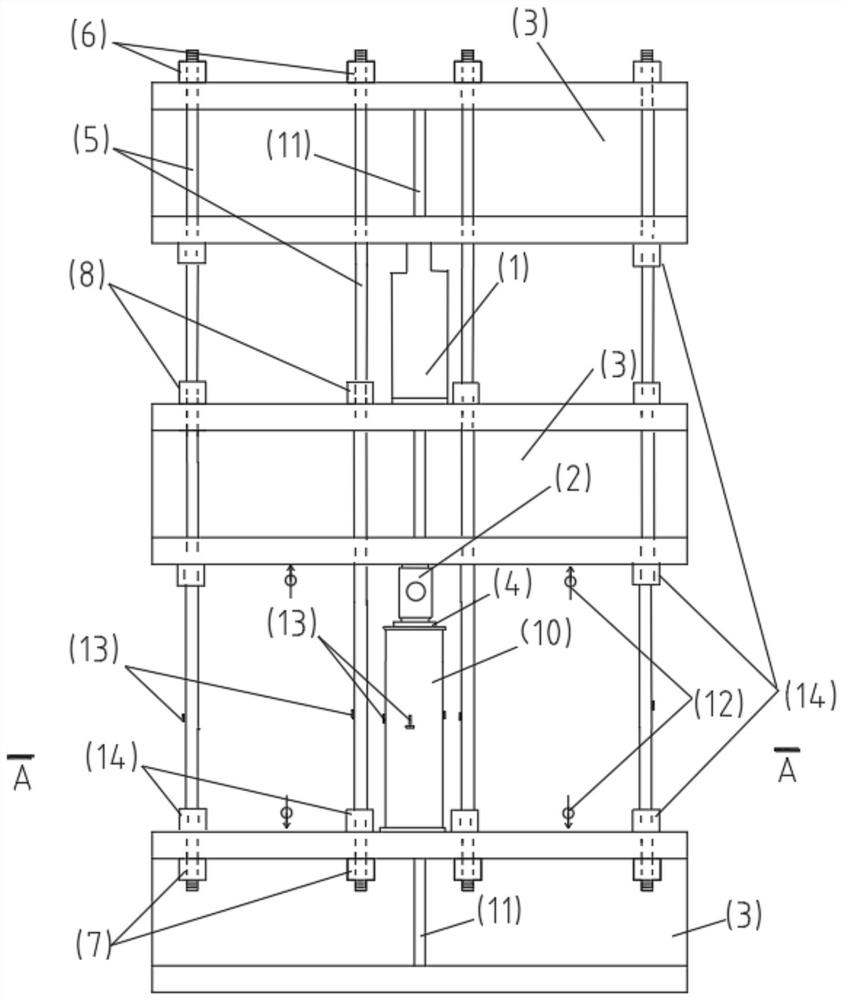

Self-balancing constant loading device for researching creep performance of concrete-filled steel tube member

A technology for loading devices and concrete components, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure test material strength, etc., which can solve the problems of difficult operation, high cost, occupation, etc., and achieve simple and convenient operation and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

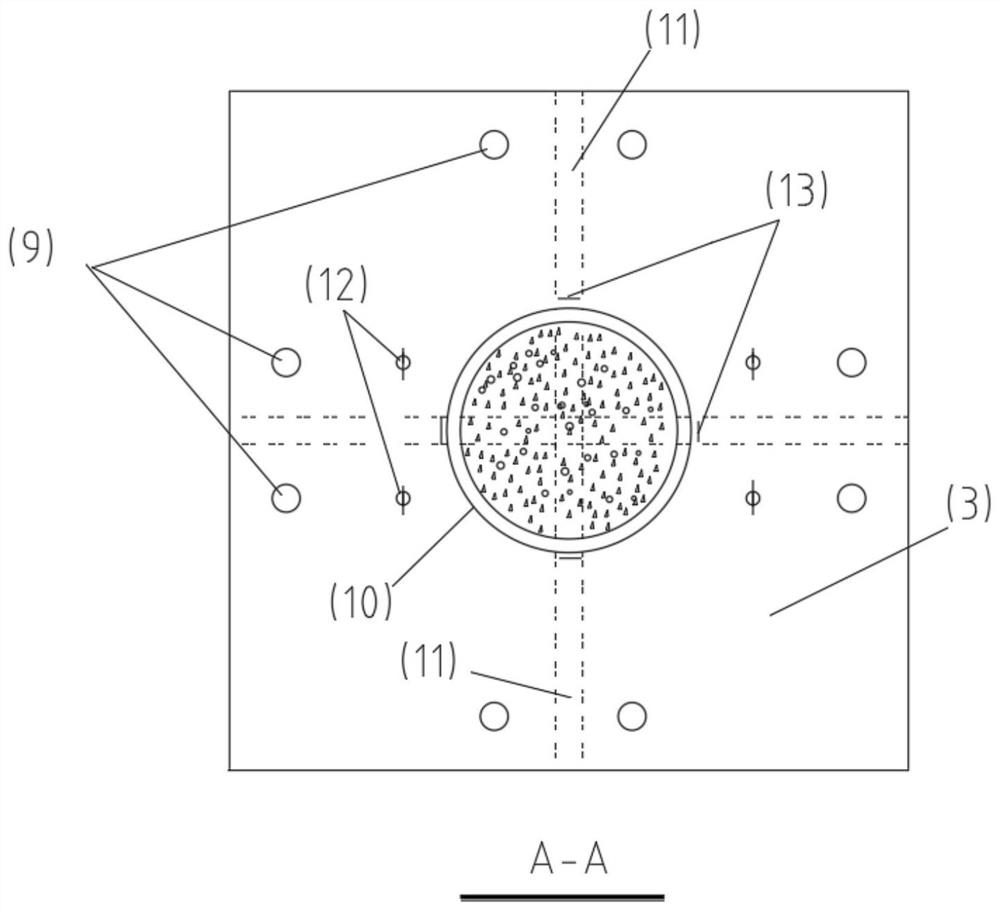

[0014] The present invention is described further below, in order to fully understand the technology of the present invention, the present invention can obviously be implemented in many other ways different from this description, and those skilled in the art can do similar according to the actual situation without violating the connotation of the present invention. Promotion and deduction, therefore, the specific content described here should not limit the protection scope of the present invention.

[0015] The illustrations of the present invention are schematic, and the illustrations are mainly for explaining the technical meaning, and are not drawn in accordance with the scale of the drawing. The specific implementation description here provides the specifications and dimensions of various specific components, but other similar specifications can be used Replacement with size should not be taken as limiting the protection scope of the present invention.

[0016] The present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com