Multi-degree-of-freedom wire harness fatigue test equipment and fatigue test method thereof

A fatigue test and degree-of-freedom technology, applied in the application field, can solve problems such as unsuitable multi-direction compliance motion, unsuitable product life verification, design redundancy, etc., to accelerate the exposure of fatigue hazards, reduce workload, Time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

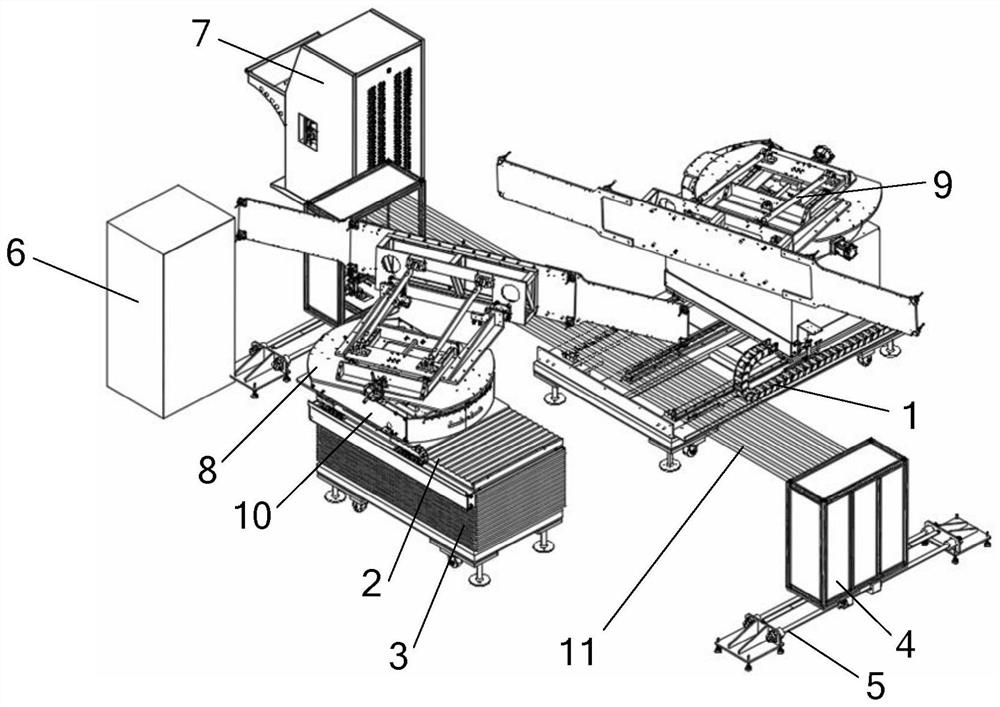

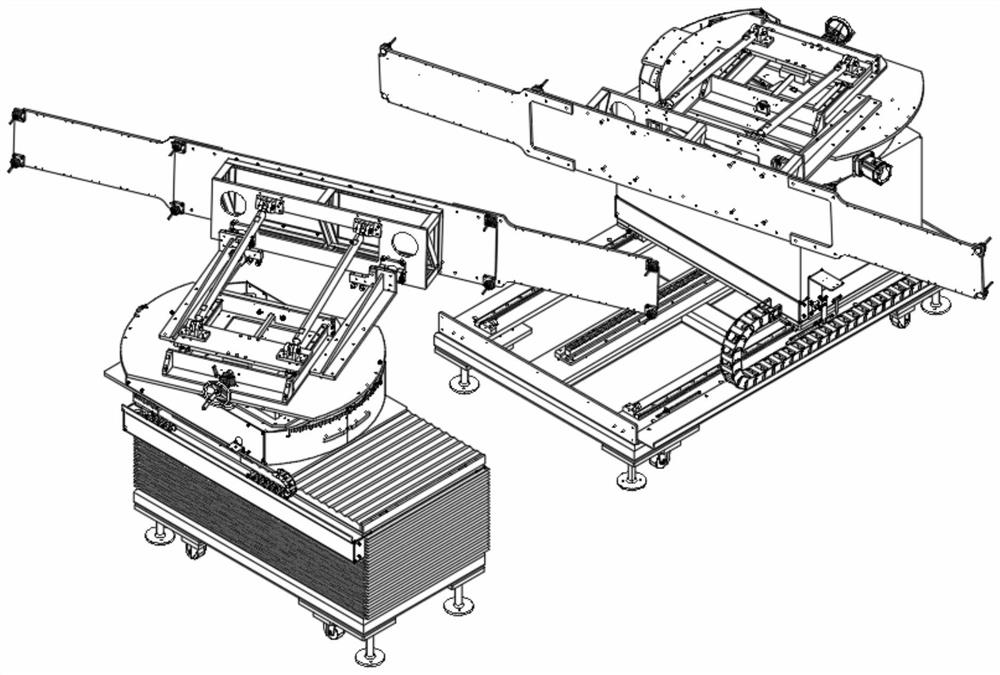

[0030] Such as figure 1 with 2As shown, the multi-degree-of-freedom wire harness fatigue test equipment includes a longitudinal movement mechanism 1, a transverse movement mechanism 2, a vertical movement mechanism 3, an angle adjustment component, a cable height detection mechanism 4, a longitudinal guide rail 5, a vertical movement linear module and a test piece Mounting plate; the cable height detection mechanism 4 is arranged between the vertical movement mechanism 1 and the lateral movement mechanism 2, including an infrared transmitter and an infrared receiver; the infrared receiver receives the light 11 emitted by the infrared transmitter; the infrared transmitter and the infrared receiver The devices are respectively driven by a vertical linear module to move up and down, and the support bases of the two vertical linear modules and the two longitudinal guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com