Method for evaluating homogenization degree of batch-processed flue-cured tobacco finished products

An evaluation method and homogenization technology, applied in the direction of instruments, complex mathematical operations, manufacturing calculation systems, etc., can solve the problems of lack of systematic quantitative evaluation of the homogenization degree of flue-cured tobacco products, so as to ensure objectivity and accuracy, and ensure the application sex, the effect of ensuring diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with specific embodiments.

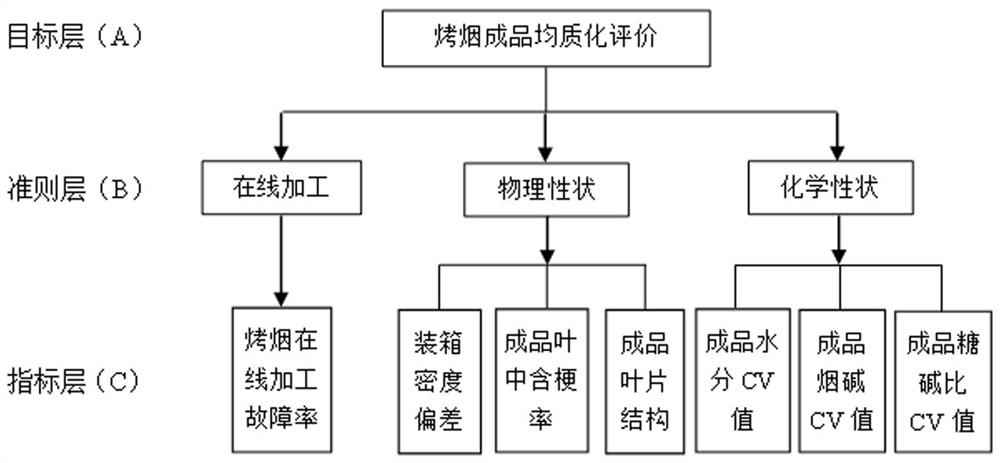

[0043] A flow chart of the evaluation method for the degree of homogenization of batch processed flue-cured tobacco products is as follows figure 1 shown, including steps:

[0044] S1: Collect the sliced tobacco samples of each finished grade of flue-cured tobacco produced in batches, and determine the data value of the homogenization evaluation index of each batch of flue-cured tobacco finished grades through detection or calculation. The grades of the finished flue-cured tobacco products are classified based on the grades of raw raw tobacco.

[0045] In the embodiment of the present invention, a total of 7 batches of flue-cured tobacco finished products are selected to collect samples of flue-cured tobacco products. The 7 batches are named A, B, C, D, E, F, and G respectively; the same batch is divided into 5 phases For sampling, 2% of the number of boxes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com