Oil-immersed three-phase transformer

A three-phase transformer, oil-immersed technology, applied in the field of transformers, can solve the problems of general heat dissipation effect of heat sinks, inaccurate temperature measurement by sensors, inconvenient handling and transportation, etc., to achieve strong heat dissipation effect, accurate measurement and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

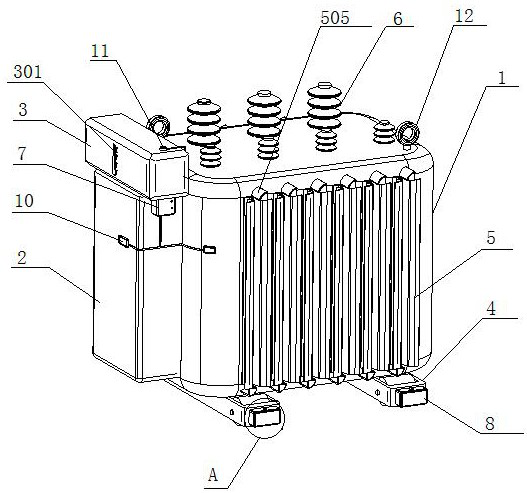

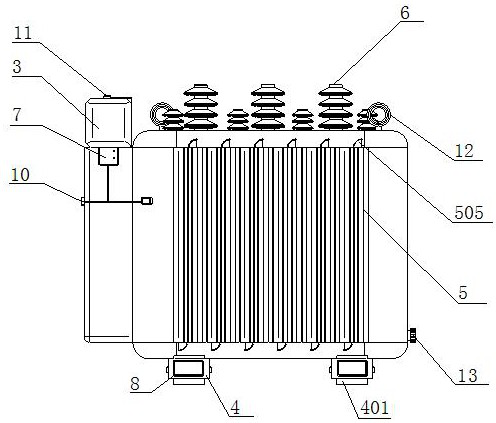

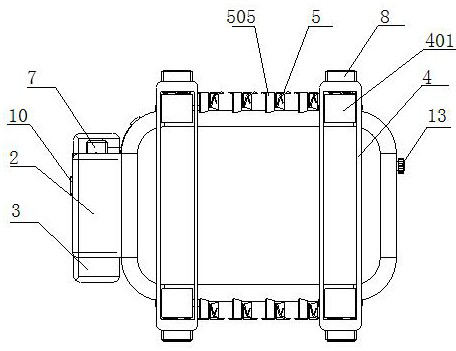

[0027]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0028]Refer toFigure 1-7 , The present invention provides a technical solution: an oil-immersed three-phase transformer includes a box body 1, the top of the box body 1 is fixedly connected with a terminal block 6, and the outer walls of the front and back sides of the box body 1 are fixedly connected with heat dissipation Structure 5, the left end of the box 1 is fixedly connected with an oil tank 2, the top of the oil tank 2 is fixedly connected with an oil pillow 3, the outer wall of the oil pillow 3 is provided with an oil level window 301, and the bottom of the box 1 is fixedly connected with two parallel Both ends of the foot 4 and the foot 4 are fixedly connected with anti-collision blocks 8, the outer wall of the oil tank 2 is close to the bottom of the oil pillow 3, and a signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com