Monitoring system with bridges for interconnecting system elements

A monitoring system, bridge circuit technology, applied in general control systems, control/regulation systems, wind turbine monitoring, etc., can solve problems such as large costs, production losses, worker injuries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Certain exemplary embodiments will now be described to provide an overall understanding of the principles of the structure, function, manufacture and use of the systems, devices and methods disclosed herein. One or more examples of these implementations are illustrated in the accompanying drawings.

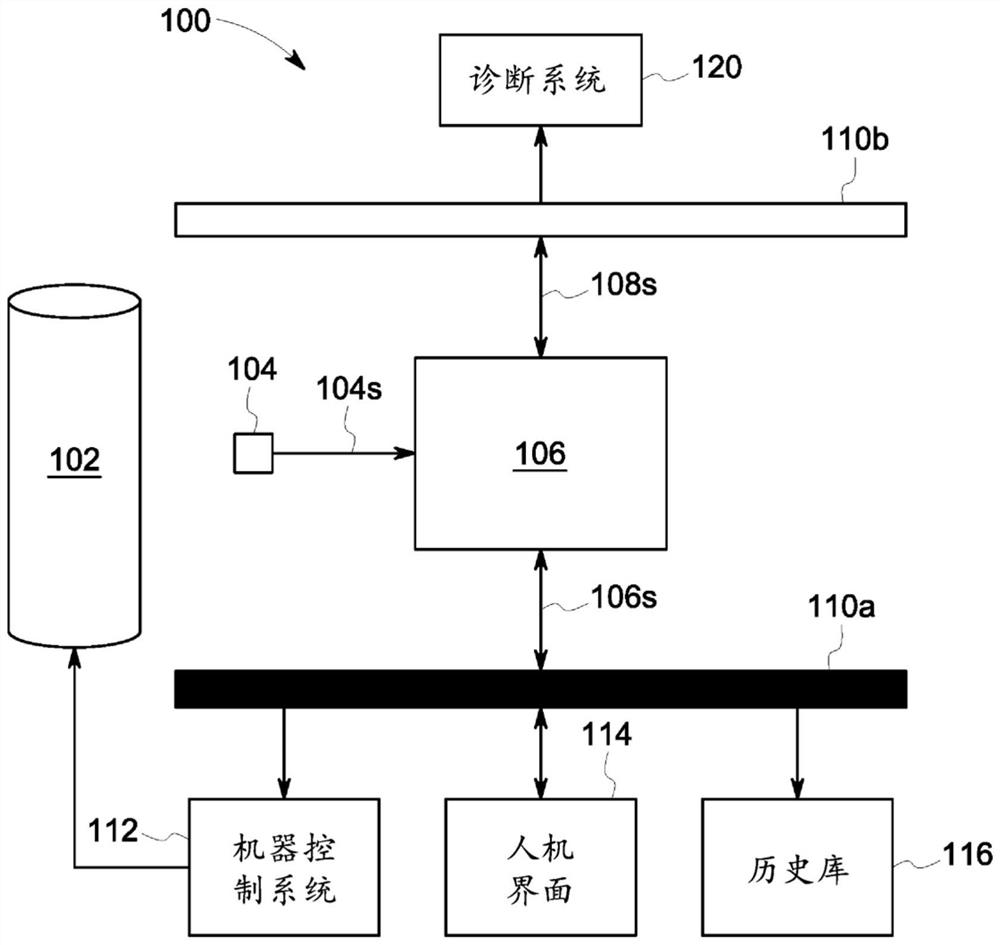

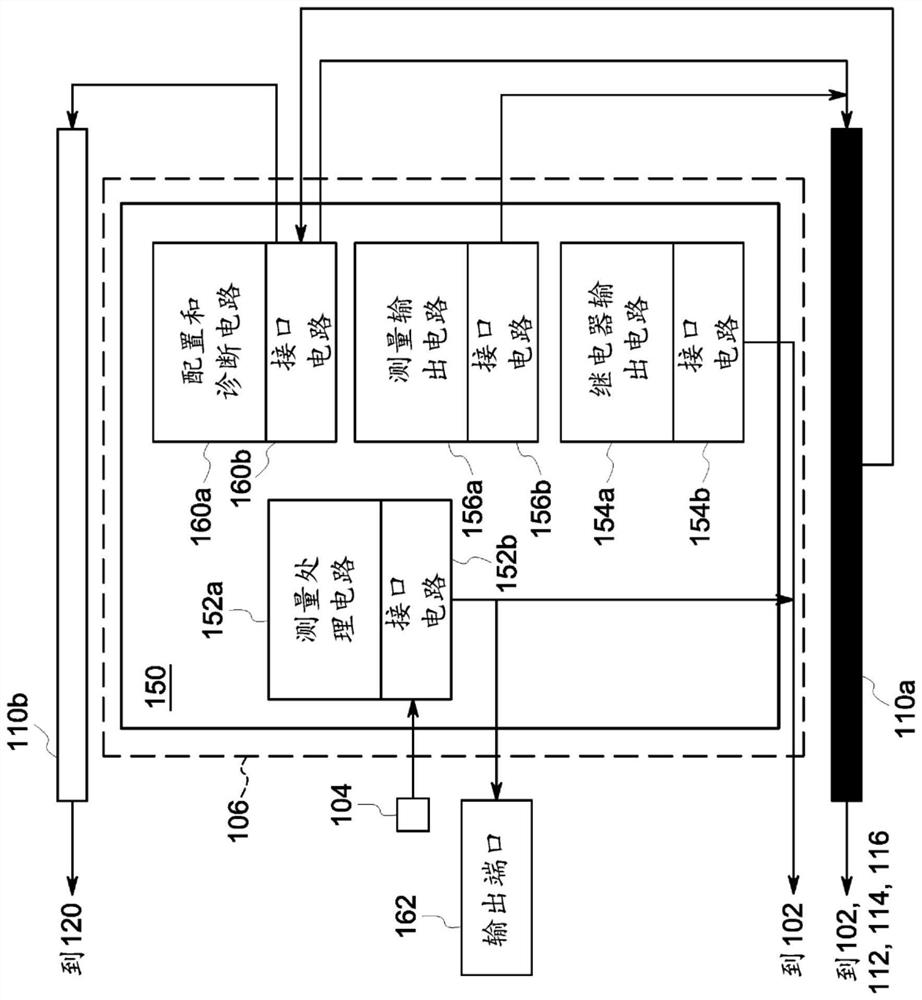

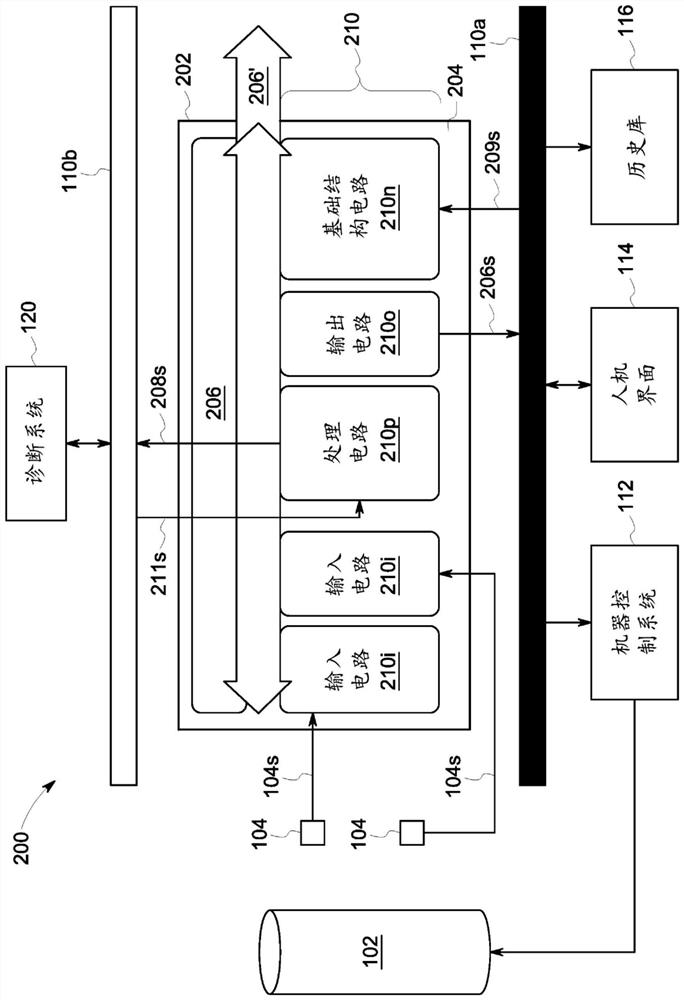

[0112] Industrial monitoring systems such as wind turbines can be used to monitor the operating conditions of industrial systems. While industrial monitoring systems may provide users with useful information about the operation of industrial systems, some monitoring systems may be limited in flexibility and / or scalability. Additionally, the cost and complexity of installation may create a significant barrier to entry for some users who want to monitor low cost and / or low priority components / systems. Systems, methods and apparatus are provided that improve the flexibility and scalability of monitoring systems. In one embodiment, a monitoring system is provided that include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap