Handheld lubricating grease applying device for installation of parts

A part installation and application device technology, which is applied to the device, coating and other directions for applying liquid to the surface, can solve the problems of inconvenient use, inconvenient control of smearing amount, inconvenient control of brush dipping amount, etc., and achieves simple operation. Convenience and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

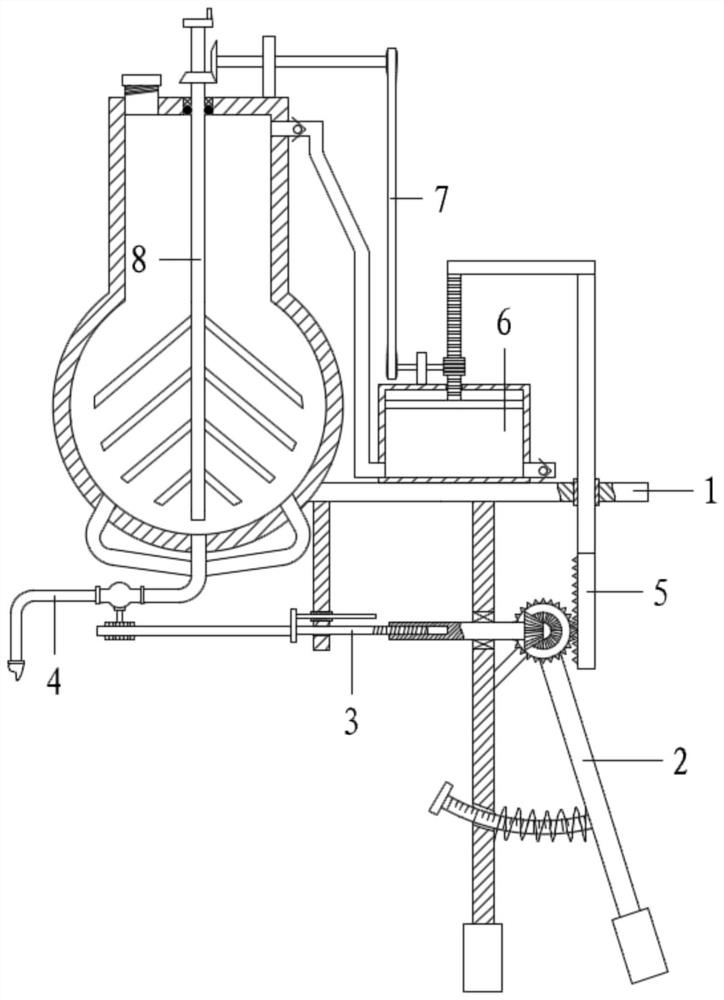

[0065] Referring to the accompanying drawings, a hand-held grease applicator for parts installation includes a frame assembly 1, a force application assembly 2, a control assembly 3, an application assembly 4, a lifting assembly 5 and a pressurization assembly 6;

[0066] The frame assembly 1 includes a support plate 101, a fat storage tank 102, a grease port 103, a sealing cover 104, a No. 1 rod 105 and a No. 1 handle 106; There is a No. 1 handle 106 connected; the fat storage tank 102 is connected to the left end of the support plate 101, the top of the fat storage tank 102 has a grease filling port 103, and the top of the grease filling port 103 is screwed with a sealing cover 104;

[0067] The support plate 101 is provided with a pressurizing component 6, which is connected to the fat storage tank 102; the right side of the No. 1 rod 105 is provided with a force applying component 2, and the force applying component 2 cooperates with the pressurizing component 6 through the...

Embodiment 2

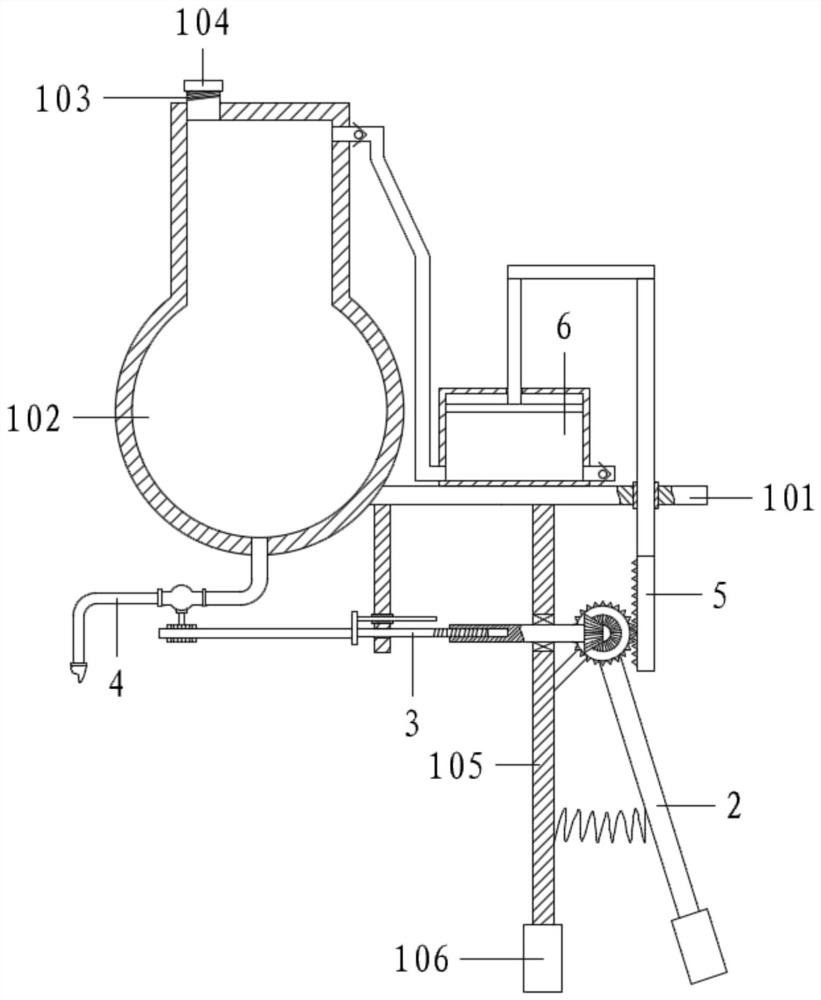

[0069] Referring to the accompanying drawings, a hand-held grease applicator for parts installation includes a frame assembly 1, a force application assembly 2, a control assembly 3, an application assembly 4, a lifting assembly 5 and a pressurization assembly 6;

[0070] The frame assembly 1 includes a support plate 101, a fat storage tank 102, a grease port 103, a sealing cover 104, a No. 1 rod 105 and a No. 1 handle 106; There is a No. 1 handle 106 connected; the fat storage tank 102 is connected to the left end of the support plate 101, the top of the fat storage tank 102 has a grease filling port 103, and the top of the grease filling port 103 is screwed with a sealing cover 104;

[0071] The support plate 101 is provided with a pressurizing component 6, which is connected to the fat storage tank 102; the right side of the No. 1 rod 105 is provided with a force applying component 2, and the force applying component 2 cooperates with the pressurizing component 6 through the...

Embodiment 3

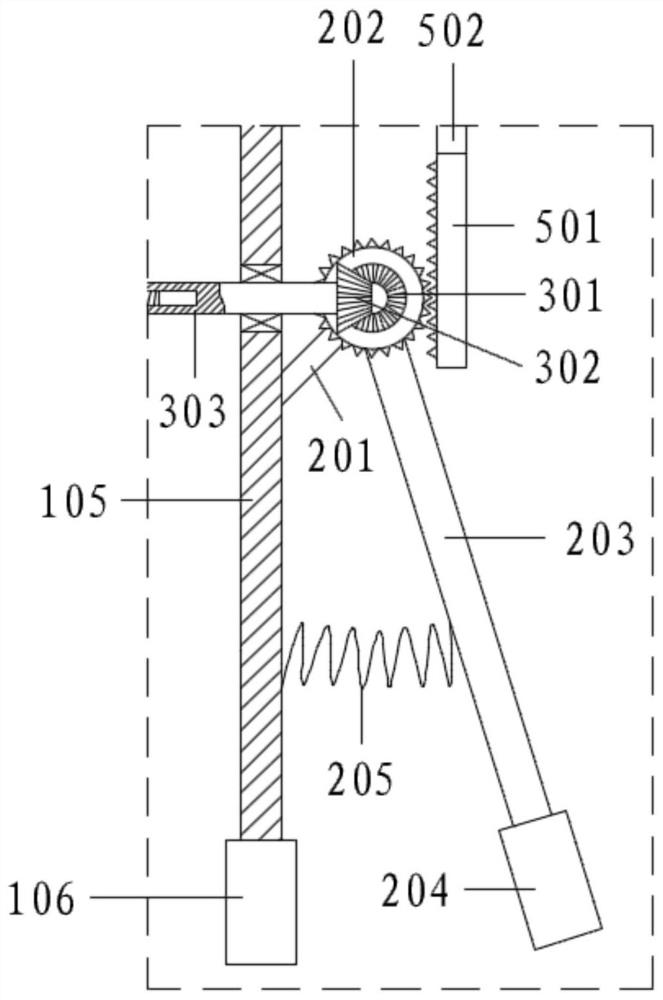

[0090] On the basis of embodiment 2,

[0091] Also includes arc rod 206 and limit block 207;

[0092] The left side of the second rod 203 is connected with an arc rod 206, and the arc rod 206 is processed with a scale line; the center of the circle corresponding to the arc rod 206 coincides with the center of the circle of the No. 1 gear 202; the arc rod 206 passes through the No. 1 rod 105, the left end is fixedly connected with the limit block 207.

[0093] Specifically, the arc-shaped rod 206 rotates with the second rod 203. On the one hand, the stability of the rotation of the second rod 203 can be improved;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com