A self-absorbing strut structure applied to small waterplane area catamaran

A technology of small water plane two-body and pillar structure, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, hull, ship construction, etc., can solve the problems that the frictional resistance of the hull cannot be significantly reduced, and the effect is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

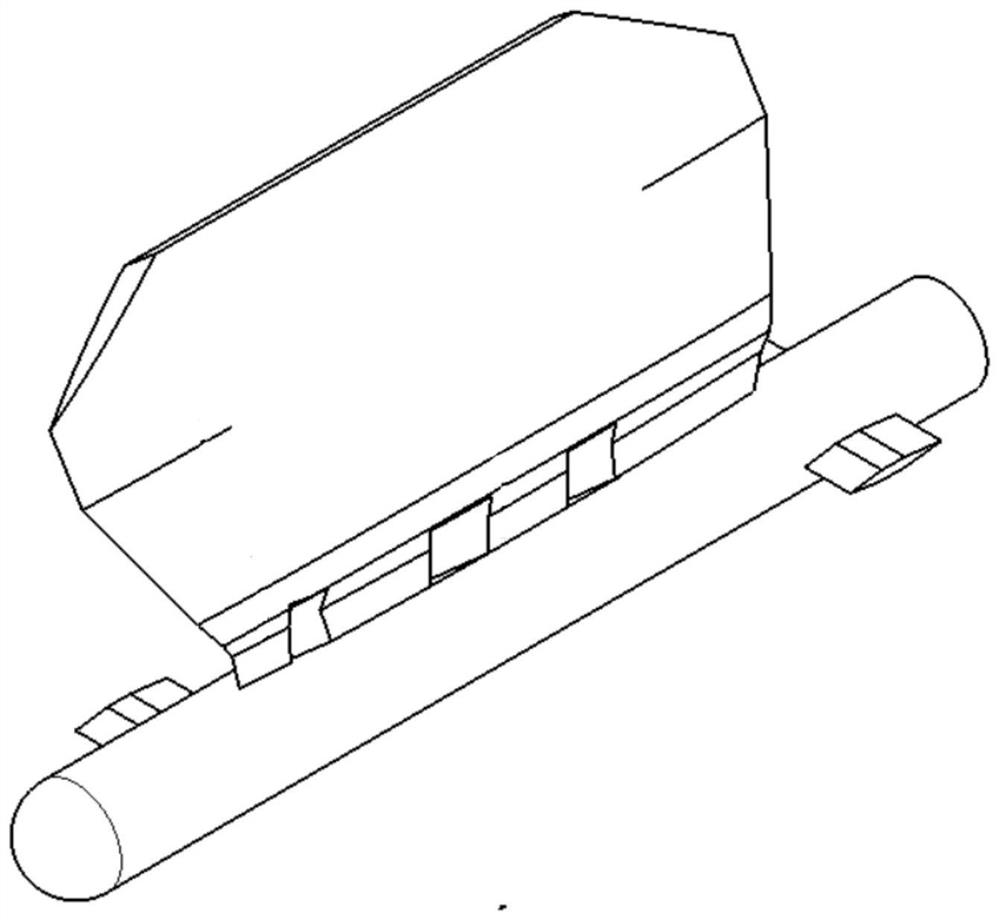

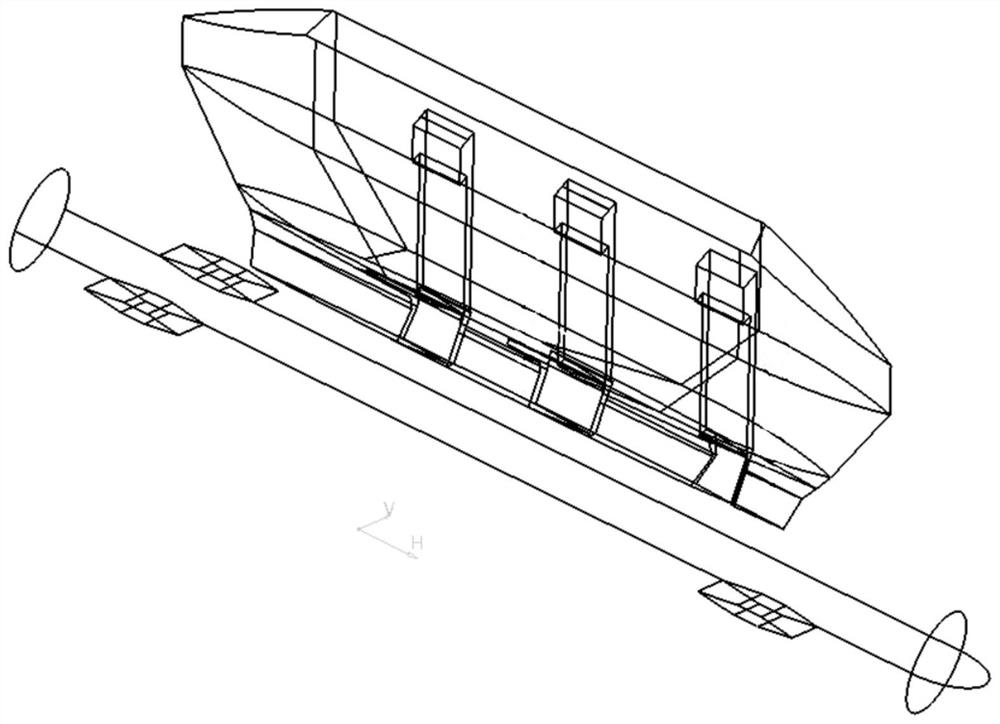

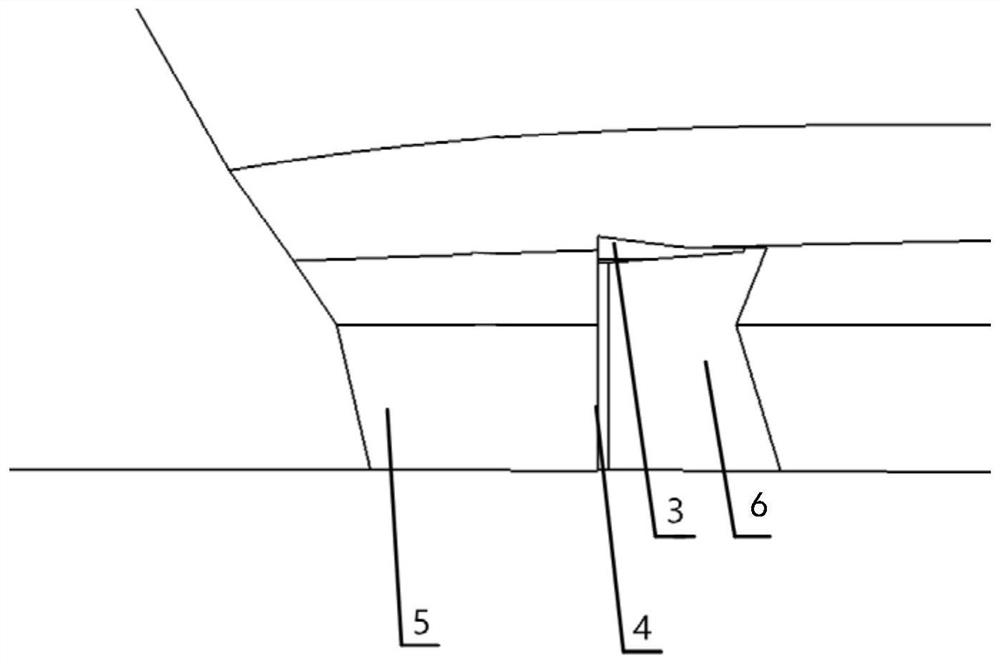

[0026] Combining Figure 1 to Figure 5 , an automatic air-breathing prop structure applied to small waterplane area catamarans according to the present invention, the structure includes 1-air inlet; 2-air inlet duct; 3-air outlet; 6-gas diversion surface; 7-pillar; the air inlet is located on the inner side of the upper end of the pillar, and the air intake duct is located inside the pillar, connecting the air inlet and the air outlet, and the front of the air outlet is a sudden contraction Cross-section, the front of the sudden shrinkage is a sharp oncoming surface, and the rear of the gas outlet is a gas diversion surface. The pillar 7 is composed of two parts above water and underwater. The front facing surface 5 of the underwater part of the pillar is sharper and perpendicular to the horizontal plane; The incoming flow expands l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com