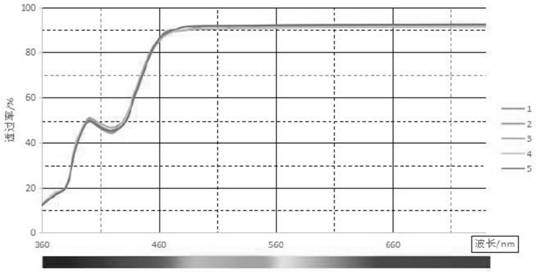

Anti-blue-ray display screen and preparation method thereof

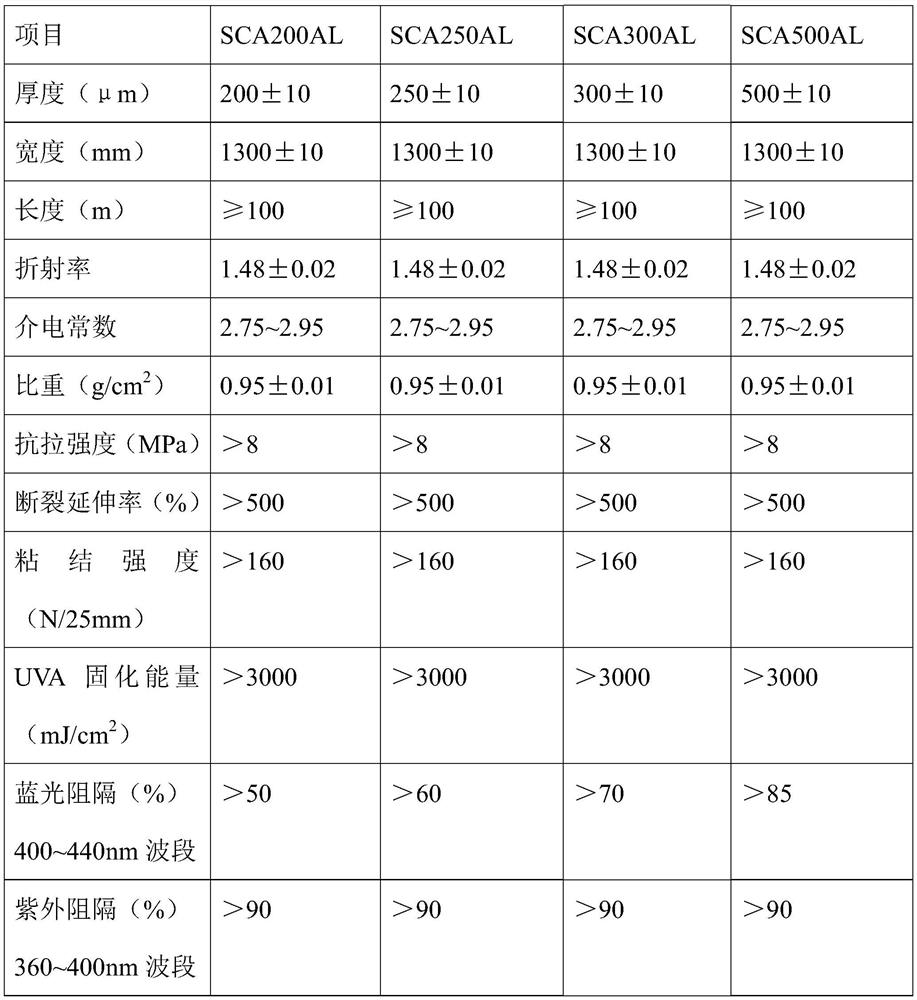

A technology for display screen and anti-blue light, applied in the field of optical film, can solve the problems of many technological processes, long processing cycle, high defect rate, and achieve the effect of reducing processes, reducing personnel and equipment costs, and low shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

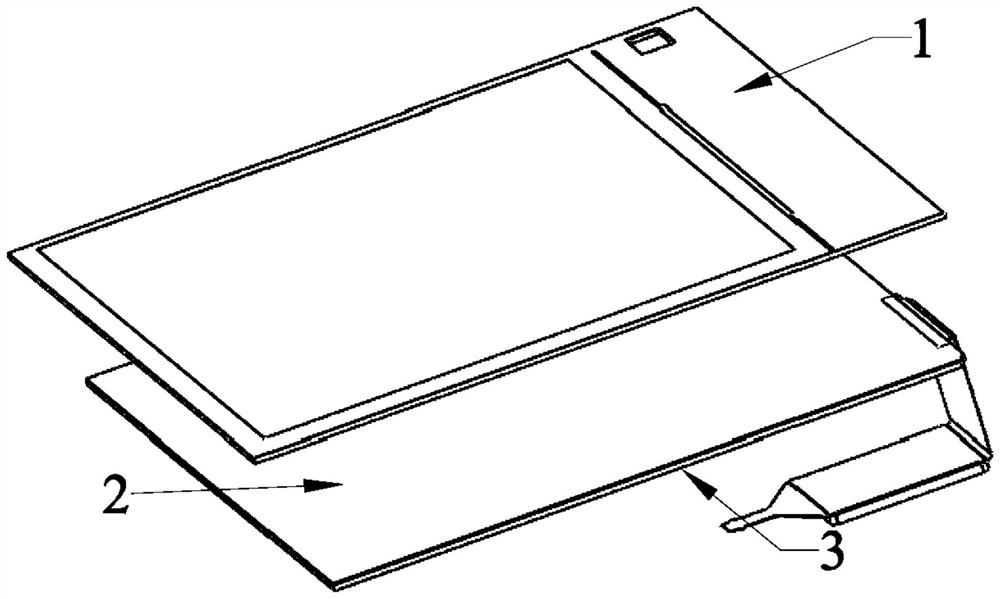

[0033] An anti-blue light display such as figure 1 As shown, it includes the display screen body. The display screen body includes a tempered glass cover plate 1 arranged from top to bottom, an optical adhesive layer 2 that blocks blue light, and an ITO glass 3. layer, with a light release layer underneath. The optical adhesive layer 2 that blocks blue light is an SCA adhesive layer.

[0034] Still further, the heavy release layer is a PE layer, and the light release layer is a PET layer.

[0035] Further, the thickness of the heavy release layer is 50 μm, and the thickness of the light release layer is 50 μm.

[0036] Still further, the thickness of the tempered glass cover plate 1 is 700 μm.

[0037] Further, the thickness of the ITO glass 3 is 400 μm.

[0038] The optical adhesive layer 2 for blocking blue light is composed of the following raw materials in weight percentage: 55g of acrylic resin, 25g of urethane acrylate polymer, 5g of aminomethoxy polymer, 12g of meth...

Embodiment 2

[0043] An anti-blue light display such as figure 1 As shown, it includes the display screen body. The display screen body includes a tempered glass cover plate 1 arranged from top to bottom, an optical adhesive layer 2 that blocks blue light, and an ITO glass 3. layer, with a light release layer underneath. The optical adhesive layer 2 that blocks blue light is an SCA adhesive layer.

[0044] Still further, the heavy release layer is a PE layer, and the light release layer is a PET layer.

[0045] Further, the thickness of the heavy release layer is 80 μm, and the thickness of the light release layer is 50 μm.

[0046] Still further, the thickness of the tempered glass cover plate 1 is 700 μm.

[0047] Further, the thickness of the ITO glass 3 is 700 μm.

[0048] The optical adhesive layer 2 for blocking blue light is composed of the following raw materials in weight percent: 50 g of acrylic resin, 28 g of urethane acrylate polymer, 8 g of aminomethoxy polymer, 9 g of methyl...

Embodiment 3

[0053] An anti-blue light display such as figure 1 As shown, it includes the display screen body. The display screen body includes a tempered glass cover plate 1 arranged from top to bottom, an optical adhesive layer 2 that blocks blue light, and an ITO glass 3. layer, with a light release layer underneath. The optical adhesive layer 2 that blocks blue light is an SCA adhesive layer.

[0054] Still further, the heavy release layer is a PE layer, and the light release layer is a PET layer.

[0055] Further, the thickness of the heavy release layer is 80 μm, and the thickness of the light release layer is 50 μm.

[0056] Still further, the thickness of the tempered glass cover plate 1 is 1100 μm.

[0057] Further, the thickness of the ITO glass 3 is 700 μm.

[0058] The optical adhesive layer 2 for blocking blue light is composed of the following raw materials in weight percentage: 48g of acrylic resin, 21g of polyurethane acrylate polymer, 14g of aminomethoxy polymer, 15g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com