Printing and dyeing pretreatment device with good liquid feeding effect

A liquid-feeding, one-to-one technology, which is applied in the field of printing and dyeing pre-treatment devices, can solve problems such as excess liquid and waste of working liquid, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

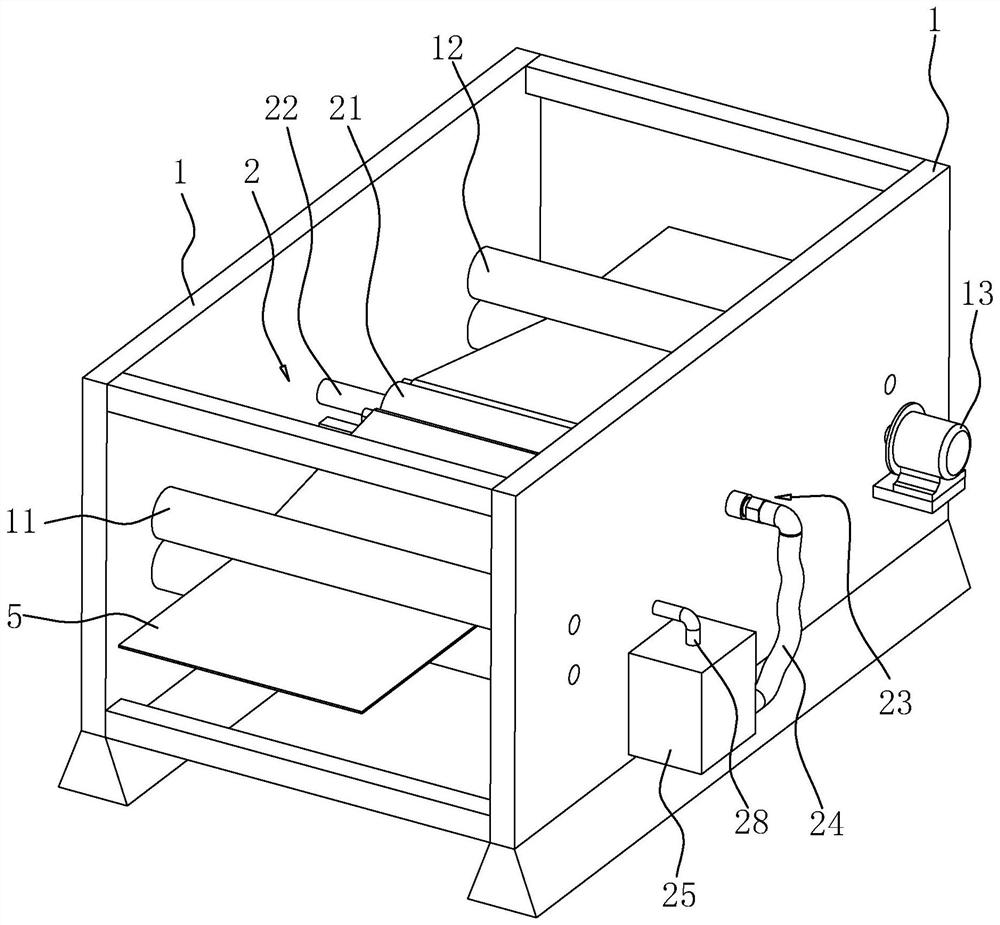

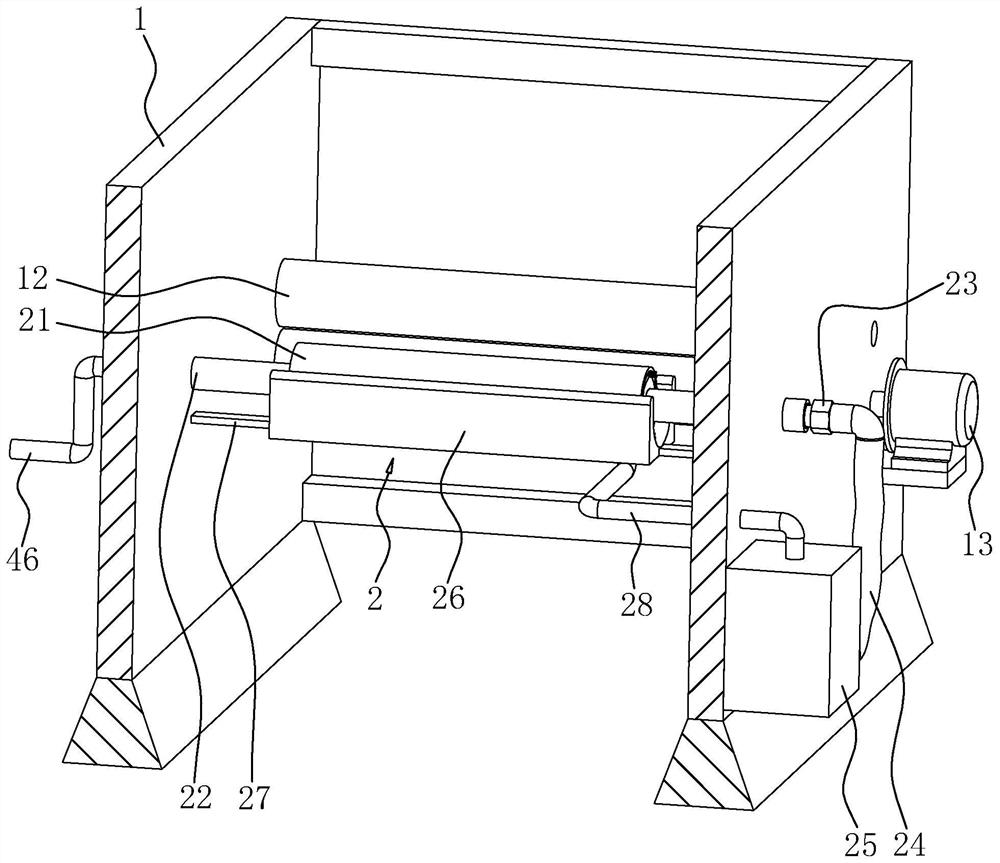

[0036] The embodiment of the present application discloses a printing and dyeing pretreatment device with better liquid supply effect. refer to figure 1 The printing and dyeing pretreatment device includes a pair of support plates 1, a pair of guide rollers 11 and a pair of power rollers 12 are rotatably connected between the pair of support plates 1, and the guide rollers 11 and power rollers 12 are respectively located near the two ends of the support plate 1. Two guide rollers 11 in a pair of guide rollers 11 are arranged up and down respectively, and two power rollers 12 between a pair of power rollers 12 are arranged up and down respectively.

[0037] A driving motor 13 is mounted on a side of one of the support plates 1 away from the power roller 12 , and the output shaft of the drive motor 13 runs through the support plate 1 transversely and is fixedly connected with one of the power rollers 12 . A liquid feeding mechanism 2 is arranged between a pair of guide rollers ...

Embodiment 2

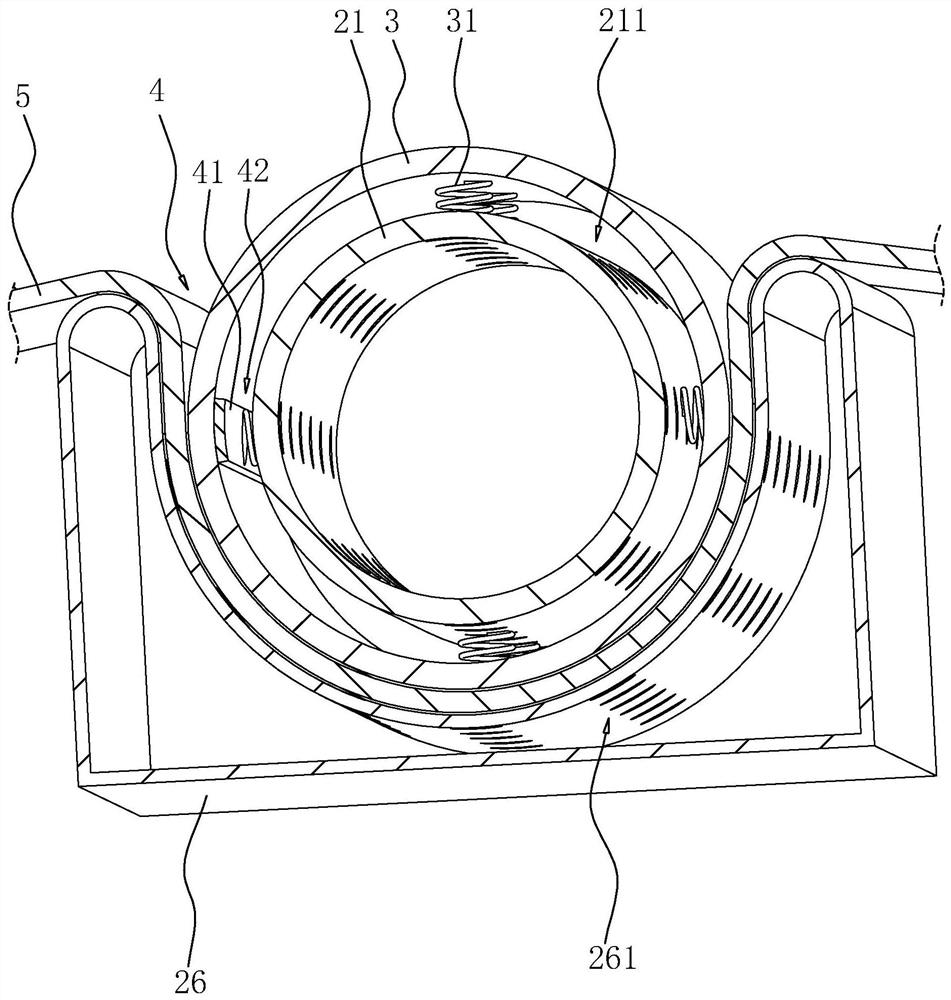

[0053] The embodiment of the present application discloses a printing and dyeing pretreatment device with better liquid supply effect. refer to Figure 5 , the difference from Embodiment 1 is that the control assembly 4 includes a first connecting rod 43 and a second connecting rod 44 arranged between the sponge layer 3 and the liquid outlet roller 21, and the first connecting rod 43 and the second connecting rod 44 The middle parts of the first connecting rod 43 and the second connecting rod 44 are rotatably connected to each other.

[0054] One end of the first connecting rod 43 near the sponge layer 3 is fixedly connected with the sponge layer 3, the end of the first connecting rod 43 away from the sponge layer 3 stretches out of the inside of the sponge layer 3, and the end of the second connecting rod 44 near the sponge layer 3 is connected to the sponge layer. 3 are fixedly connected and protrude from the inside of the sponge layer 3 . An installation spring 45 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com