Novel steel sleeve device for cast-in-situ bored pile construction

A technology of bored cast-in-place piles and steel casings, which can be used in sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as great influence on bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

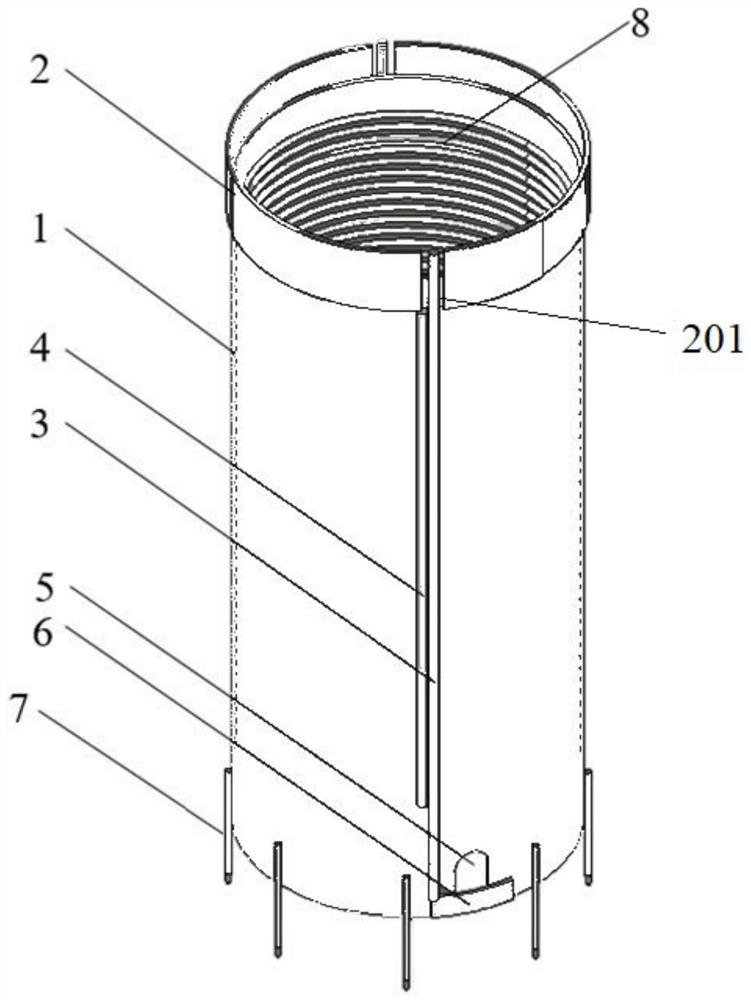

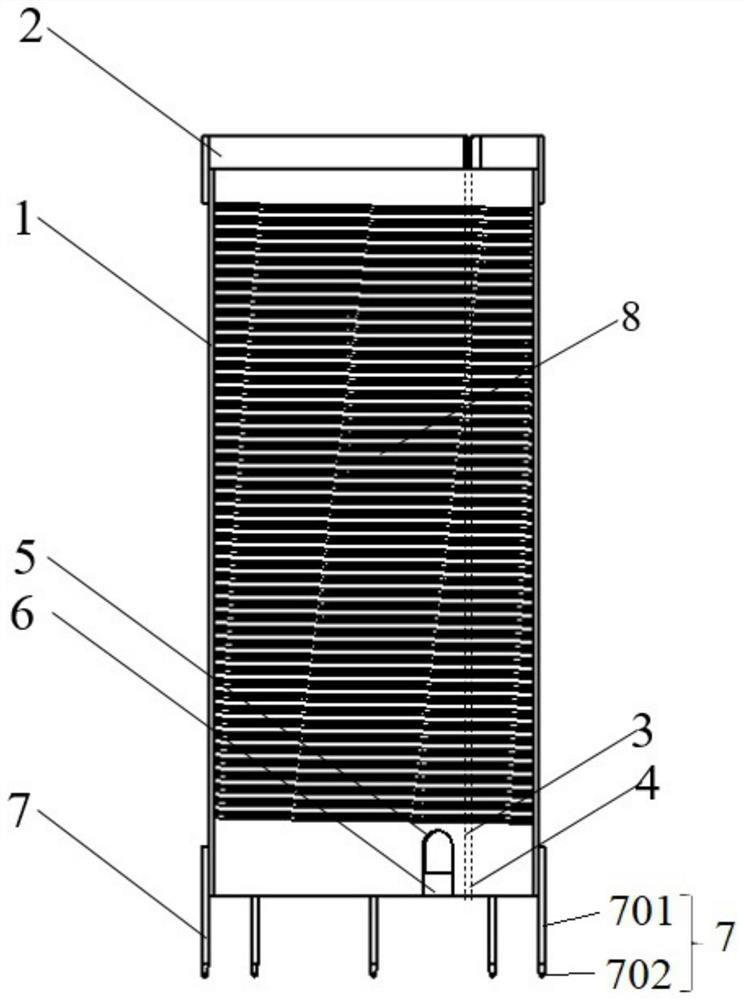

[0024] Such as figure 1 , 2 As shown, a novel steel casing device for bored pile construction, the device includes a plurality of sequentially socketed steel casing 1 ( figure 1 , 2 Only one steel casing 1), at least one water injection pipe 3 (two water injection pipes 3 are provided in this embodiment and distributed symmetrically), multiple drill bits 7, pressure relief hole baffle plate 6, The water injection pipe protection pipe 4, the upper and lower ends of the steel casing 1 are open, the axial length of the steel casing 1 is 2.0-2.4m, preferably 2.0m, the outer diameter is 0.8-1.2m, preferably 1.0m, and the wall thickness 15-17mm, preferably 16mm, made of high-strength steel (such as Q460 steel). On the outer wall of the pipe 1, the width of the casing lap plate 2 (the direction of the width is parallel to the axis of the steel casing 1) is 20cm, which is divided into two parts on average, the 10cm width of the upper part and the upper steel casing The 10cm part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com