Multi-arch tunnel middle wall steel frame laying method

A technology for multi-arch tunnels and steel frames, which is applied in tunnels, tunnel linings, mining equipment, etc., and can solve problems such as failure to meet safety requirements for multi-arch tunnel construction, disconnection between on-site construction process and design, and complex construction methods for multi-arch tunnels. , to achieve effective resistance to surrounding rock deformation, reasonable force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

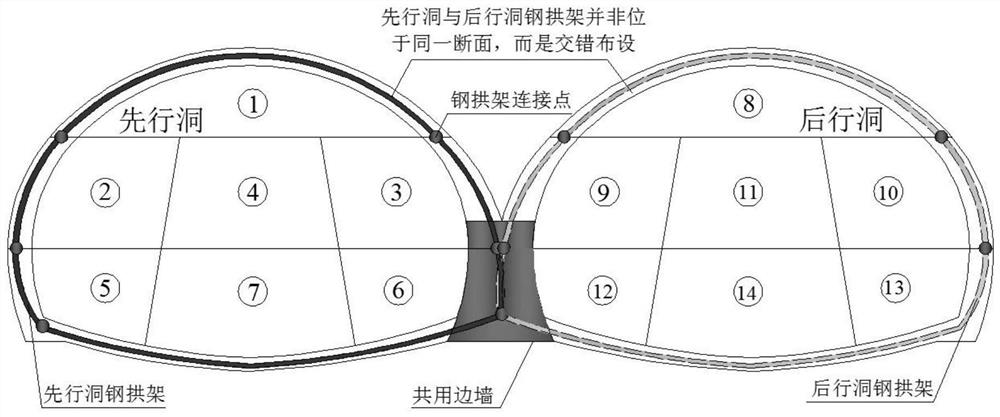

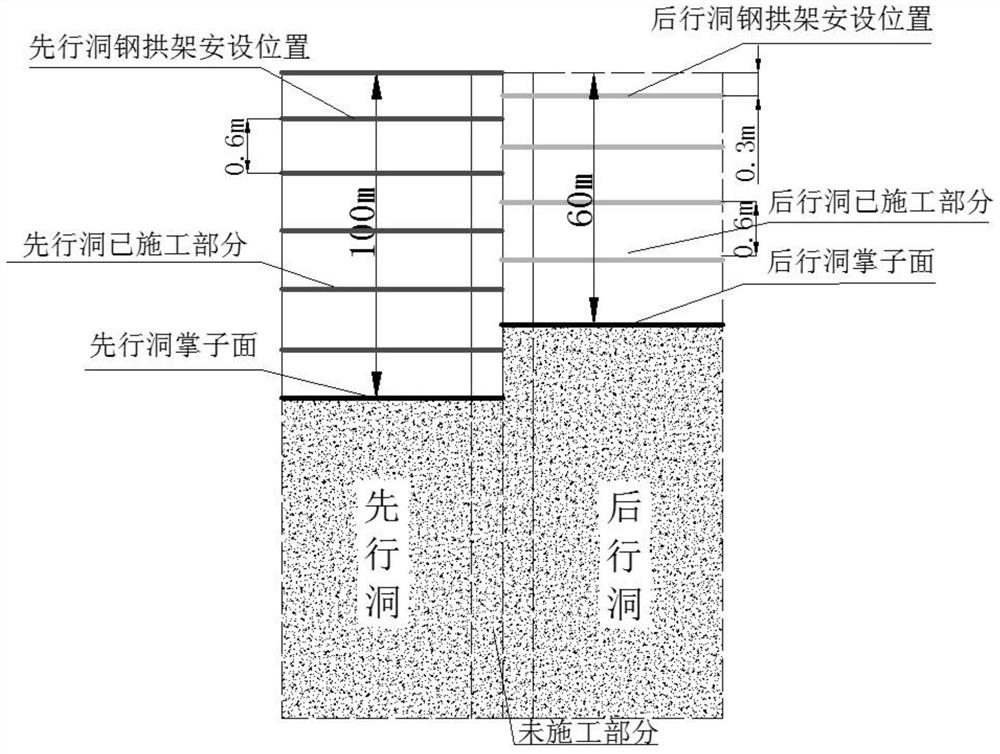

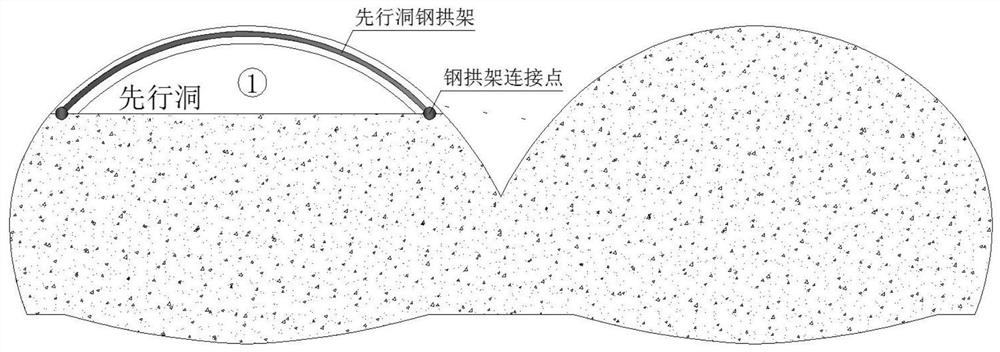

[0039] A method for laying steel frames in the middle wall of a multi-arch tunnel. Independent steel arch structures are respectively arranged in the double holes of the multi-arch tunnel. The steel arch structures of the leading hole and the rear hole are staggered and independently arranged. Pre-embed the lower steel frame on the side close to the common side wall of the rear tunnel into the shared side wall of the first tunnel. fixed to form a complete rear tunnel steel arch structure.

[0040] The steel arch structure includes an upper steel frame, a middle steel frame, a lower steel frame and an inverted arch steel frame. The steel frame is processed and formed outside the hole according to the design requirements, and the installation in the hole is carried out after the primary sprayed concrete. In order to ensure the overall stability and effectiveness of the steel frame, the steel frame is connected with the positioning tie bars and anchor rods during installation. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com