X-ray tank detection device

A detection device, X-ray technology, which is applied in measurement devices, optical devices, material analysis using radiation, etc., can solve the problems of high input cost, labor, and low degree of automation, and achieves a high degree of automation and measurement data. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

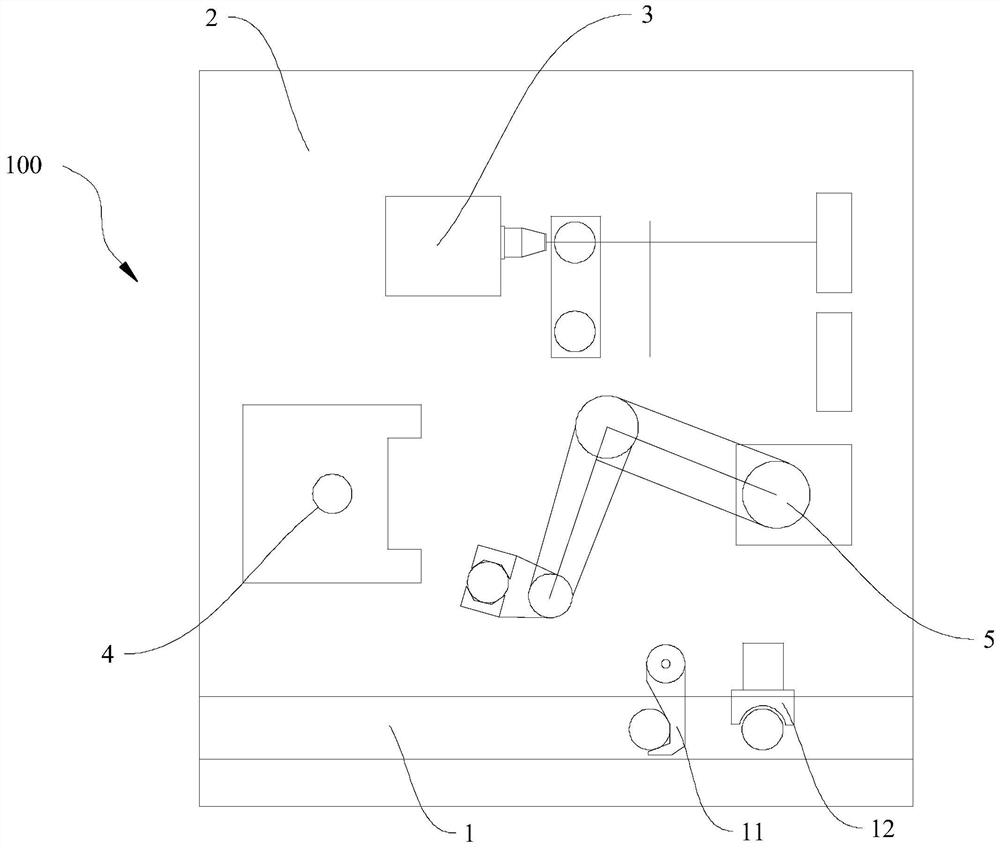

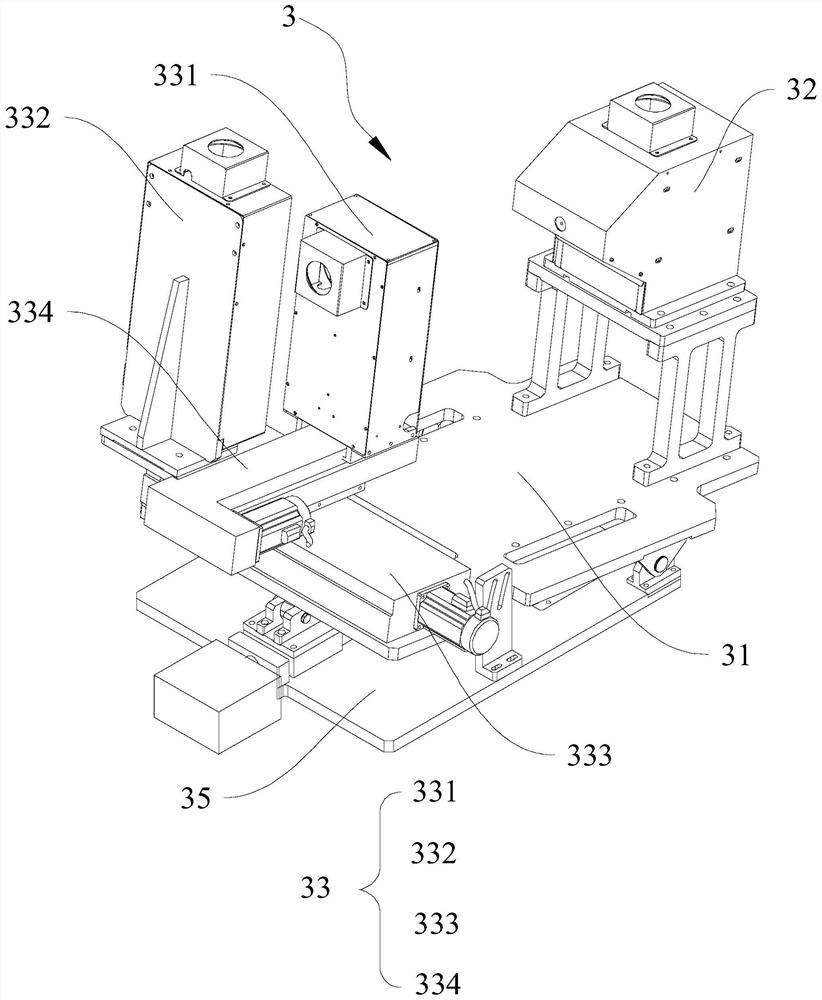

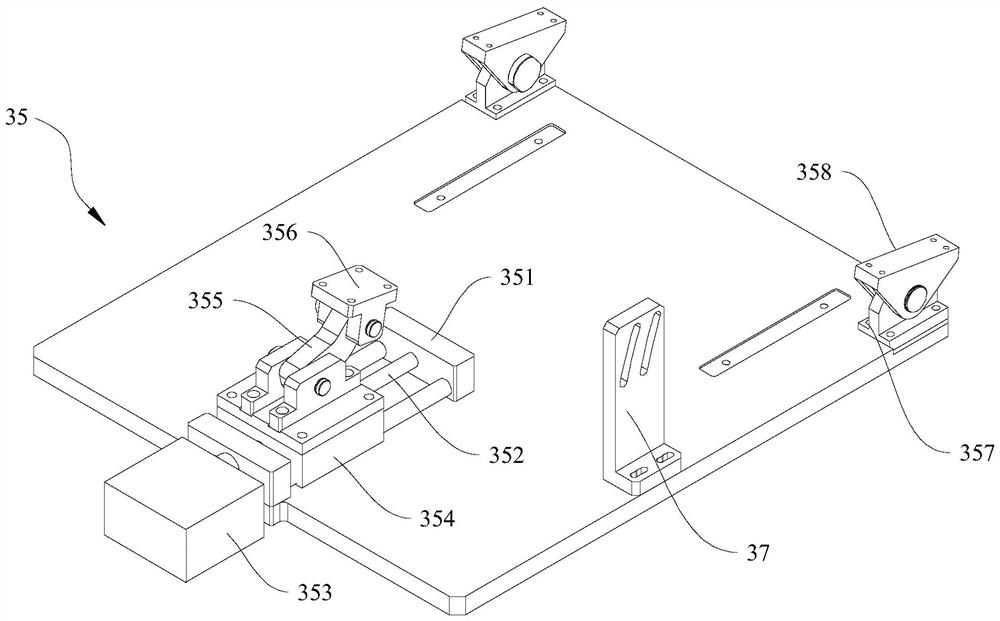

[0034] The X-ray can detection device 100 of the present invention is as Figure 1-Figure 12 As shown, it includes a conveying line 1 for conveying the can body, a bottom plate 2 arranged on the side of the conveying line 1, an X-ray scanning forming device 3 for detecting the crimping data of the can body, and an X-ray scanning forming device 3 for detecting the outer dimension of the can body The tank external dimension measuring device 4, the manipulator 5 for clamping and transporting the tank body to be tested, and the industrial computer, the X-ray scanning forming device 3, the tank external dimension measuring device 4 and the manipulator 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com