Systems, methods, and media for artificial intelligence feedback control in additive manufacturing

A technology of additive manufacturing and artificial intelligence, applied in the direction of manufacturing tools, additive processing, liquid material additive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

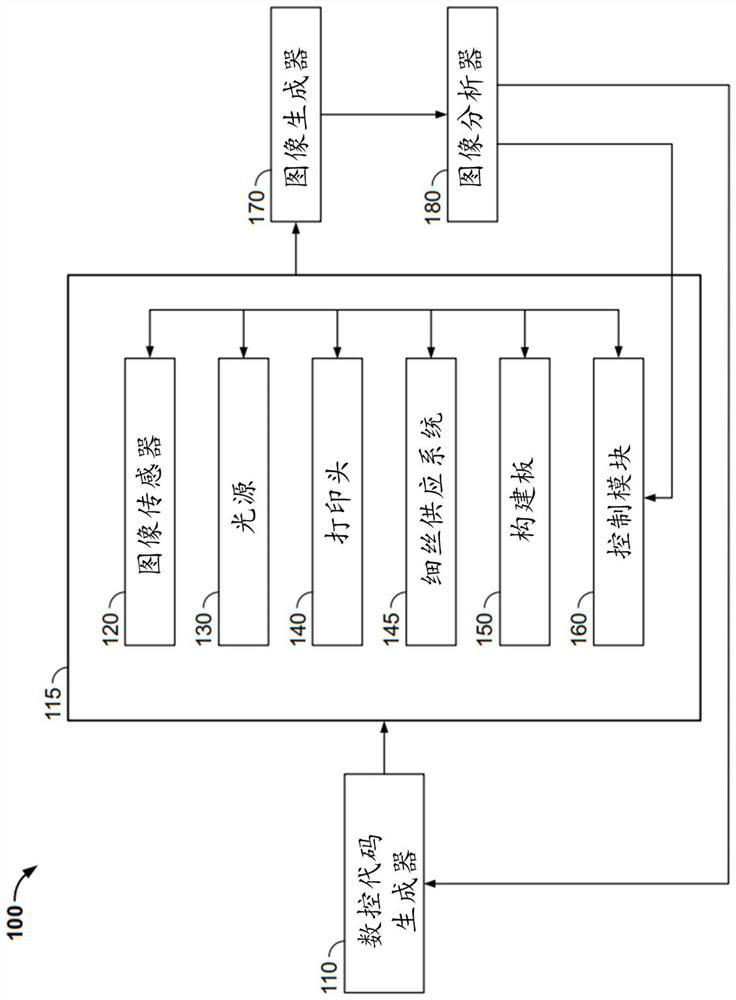

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 8

[0097] Figure 8 An example 800 of a training process for learning anomaly patterns and rates based on different infill densities and infill patterns and how the anomaly patterns and rates affect the mechanical properties of printed objects is shown, in accordance with some embodiments.

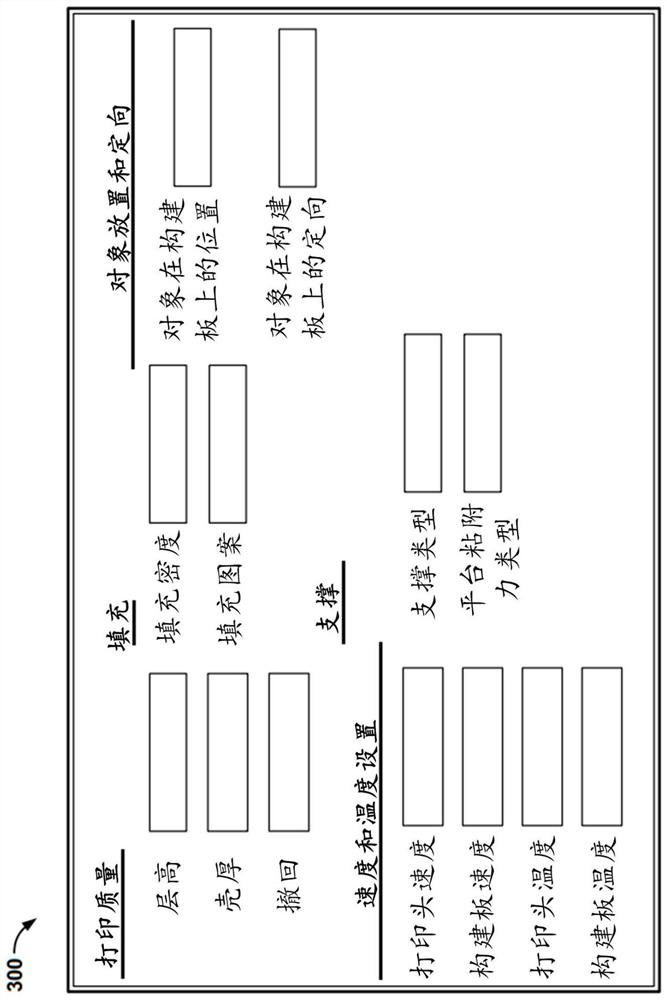

[0098] At 810, one or more printing parameters that affect mechanical properties of the object can be identified. For example, infill density and infill pattern can be identified as affecting the mechanical properties of an object. In some embodiments, artificial intelligence algorithms can be used to identify other printing parameters that affect the mechanical properties of the object.

[0099] At 820, a predetermined number ("group") of target objects may be printed, and one or more printing parameters that have been identified as affecting mechanical properties of the target objects may remain the same for the entire group. For example, you can specify the same hatch pattern and fill de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com