Raw material quantitative feeding device for food processing

A quantitative feeding and food processing technology, which is applied in transportation and packaging, dissolving, mixing machines, etc., can solve problems such as uneven mixing and increased labor intensity of workers, so as to reduce labor intensity, improve food production efficiency, and improve continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

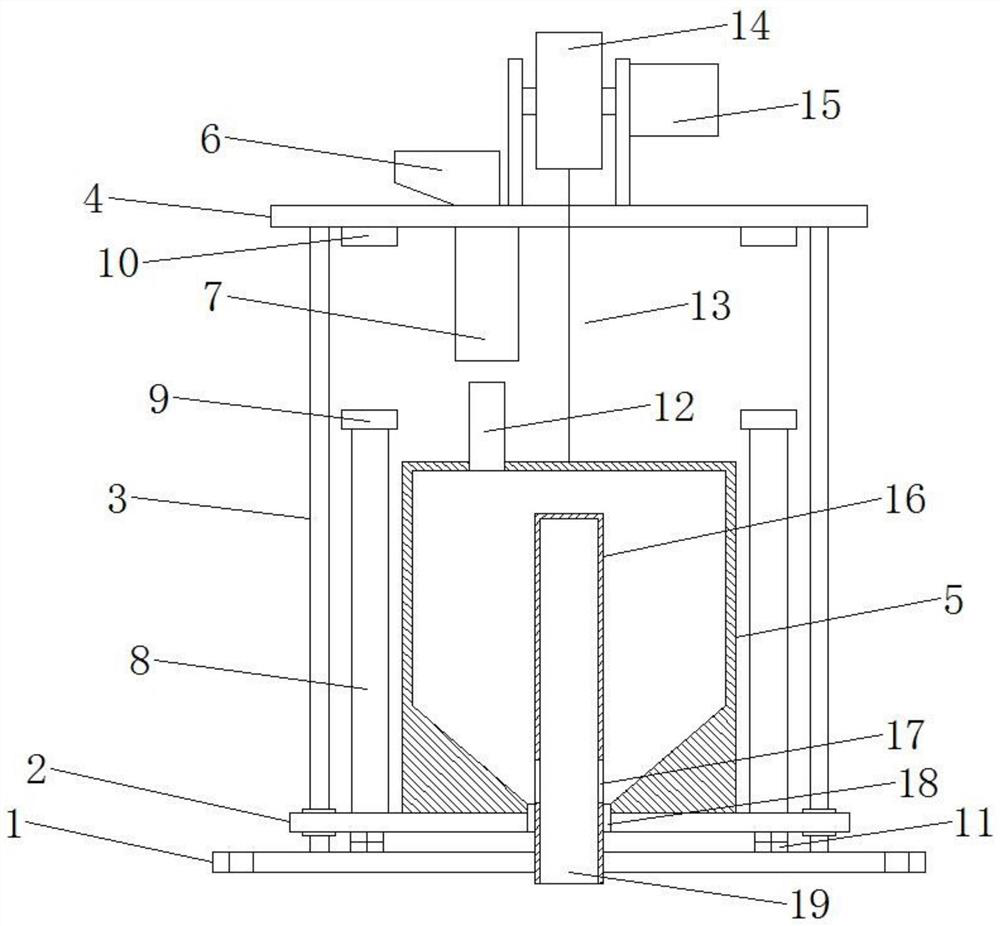

[0022] Please refer to the figure, in the embodiment of the present invention, a quantitative feeding device for raw materials for food processing includes a mounting plate 1, a lifting plate 2, a support rod 3 and a top plate 4; the lifting plate 2 is horizontally arranged above the mounting plate 1 , the four corners of the lifting plate 2 are provided with vertical support rods 3 through sliding sleeves, the lower ends of the support rods 3 are fixedly connected to the upper surface of the mounting plate 1, and the upper ends of the support rods 3 are fixedly connected to the lower surface of the horizontal top plate 4. The top plate 4 is supported by the support rod 3, and the lifting plate 2 only moves in the vertical direction under the action of the support rod 3 to change the height.

[0023] The lifting plate 2 is coaxially fixed with a vertical storage tube 5, and the bottom of the storage tube 5 is provided with a funnel-shaped structure, so that the food raw materia...

Embodiment 2

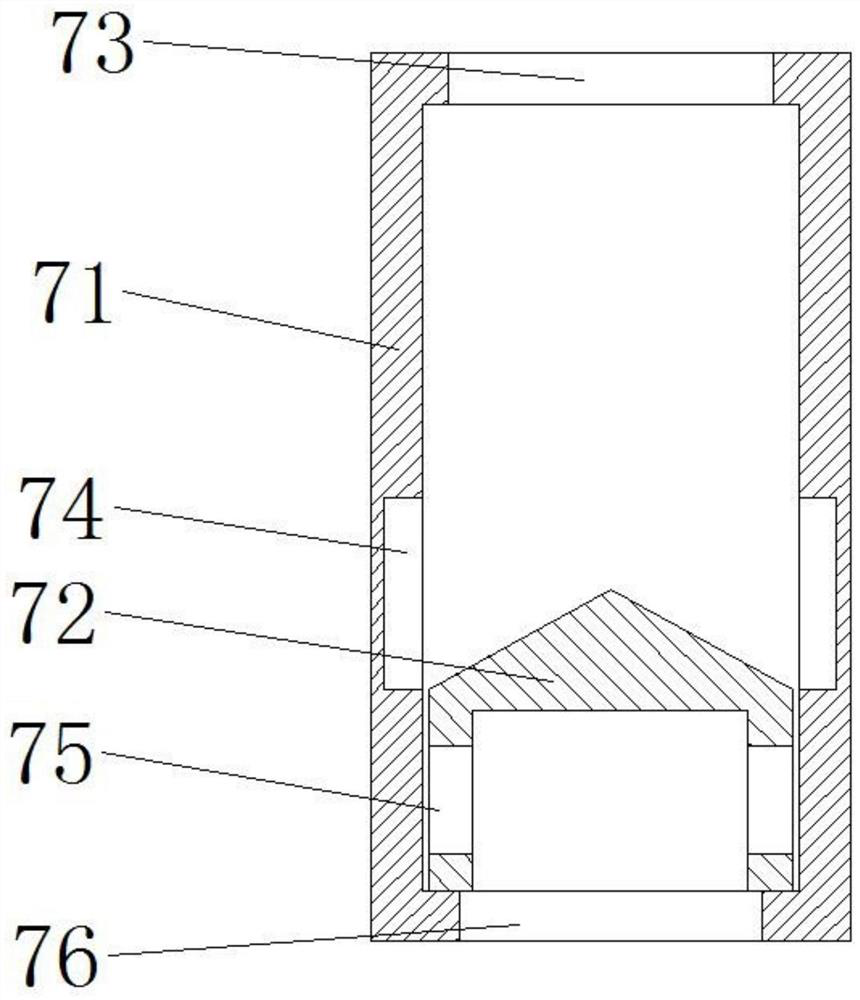

[0027] On the basis of Embodiment 1, a vertical unloading mechanism 7 is fixedly installed on the corresponding top plate 4 directly above the movable connecting pipe 12, and the movable connecting pipe 12 can extend into the unloading mechanism 7 to pass the raw material through The flexible connecting pipe 12 enters into the storage cylinder 5 .

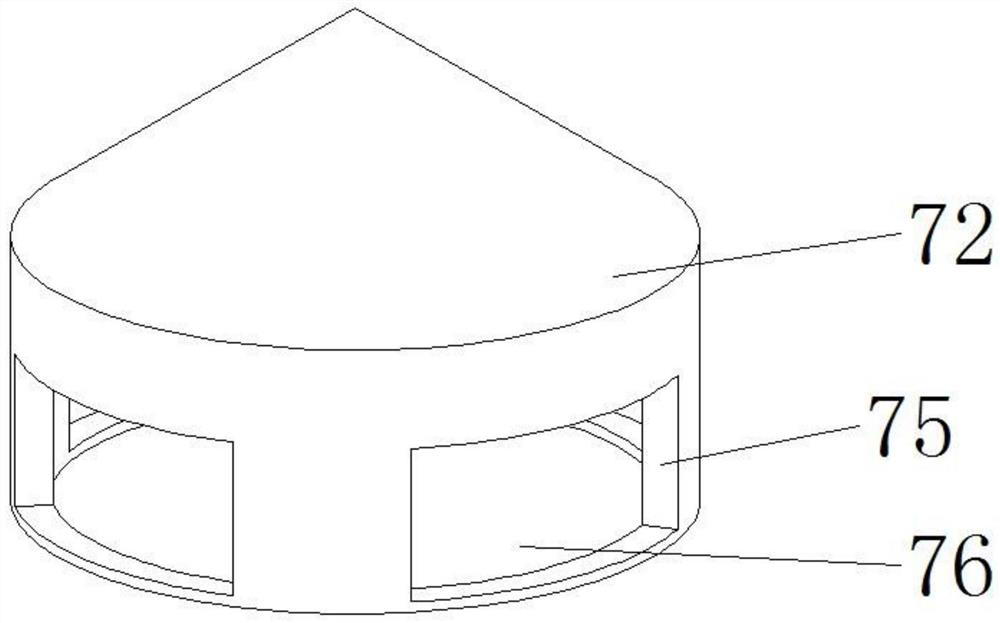

[0028]The blanking mechanism 7 includes a tube body 71 with a cylindrical structure and a movable plug 72 that fits with its internal clearance in the tube body 71. The movable plug 72 moves up and down in the tube body 71, and the top of the movable plug 72 is arranged It is a conical structure, and the food raw materials falling on the movable plug 72 are transported to the surrounding edge; the top of the pipe body 71 is set as a feed port 73, and the upper end is connected with the feed hopper 6 on the top plate 4, so that the raw materials can be fed from The feed hopper 6 is loaded into the top plate 4, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com