Pig iron perforating device based on circulation of cooling liquid

A drilling device and coolant technology, applied in drilling/drilling equipment, boring machine/drilling machine components, maintenance and safety accessories, etc., can solve the problem of increased processing costs, heating of the drilling mechanism, waste of coolant, etc. Problems, to achieve effective cooling treatment, to avoid the effect of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

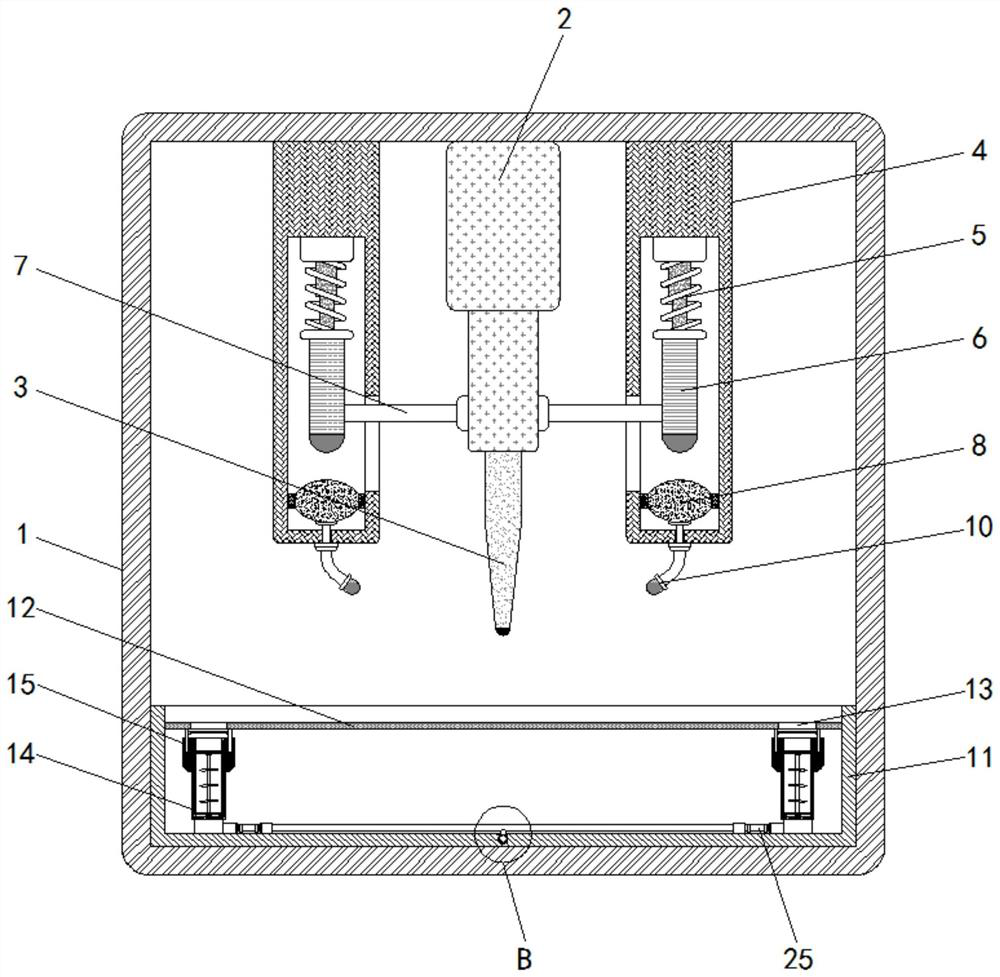

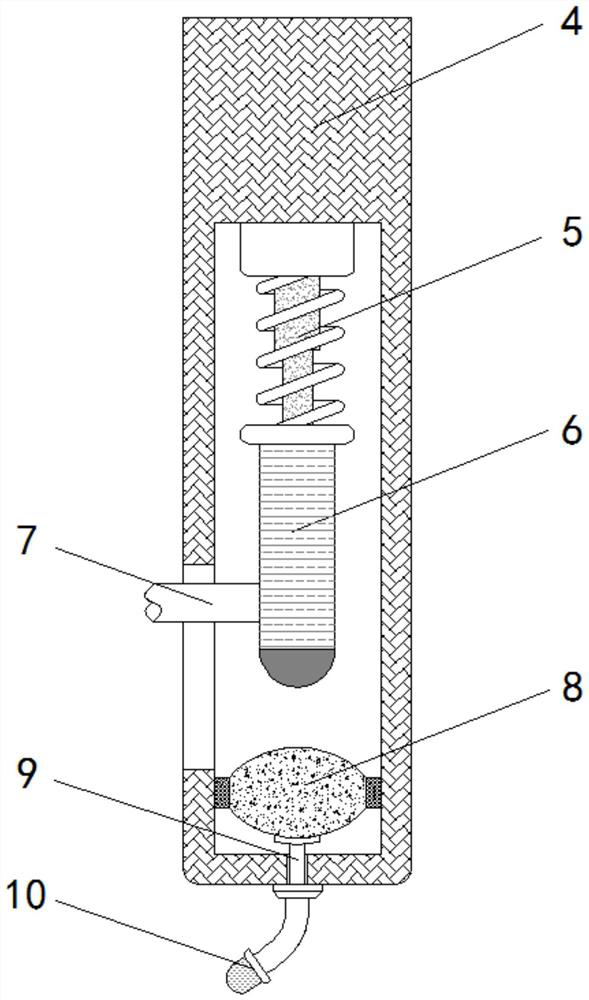

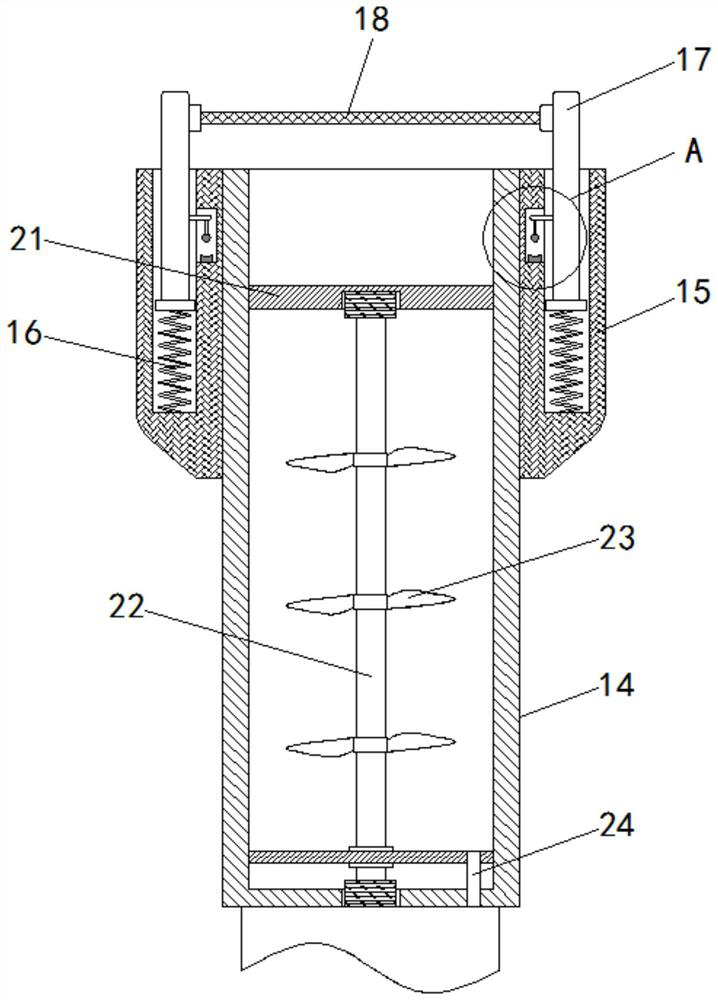

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] as attached figure 1 to attach Figure 6 Shown:

[0027] The invention provides a pig iron punching device based on cooling liquid circulation, which includes a main body 1, an electric push rod 2 and a fixing part 4 are installed inside the main body 1, and a punching mechanism 3 is installed on the lower end of the electric push rod 2 to fix the There is a groove inside the part 4, and a reset mechanism 5 is installed inside the groove, and a movable rod 6 is fixedly installed at the lower end of the reset mechanism 5, and a connecting rod 7 is fixedly installed between the electric push rod 2 and the movable rod 6. The punching mechanism 3 utilizes the connecting rod 7 to drive the movable rod 6 to move downward together. The interior of the fixed part 4 is provided with a coolant air bag 8 installed on the central axis of the lower end of the movable rod 6. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com