General platform device for nuclear facility retirement

A general platform, nuclear facility technology, applied in the direction of claw arm, manipulator, chuck, etc., can solve the problems of long arm span, high radioactive pollution, low operation accuracy, etc., to improve work efficiency, solve the problem of small bearing capacity and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

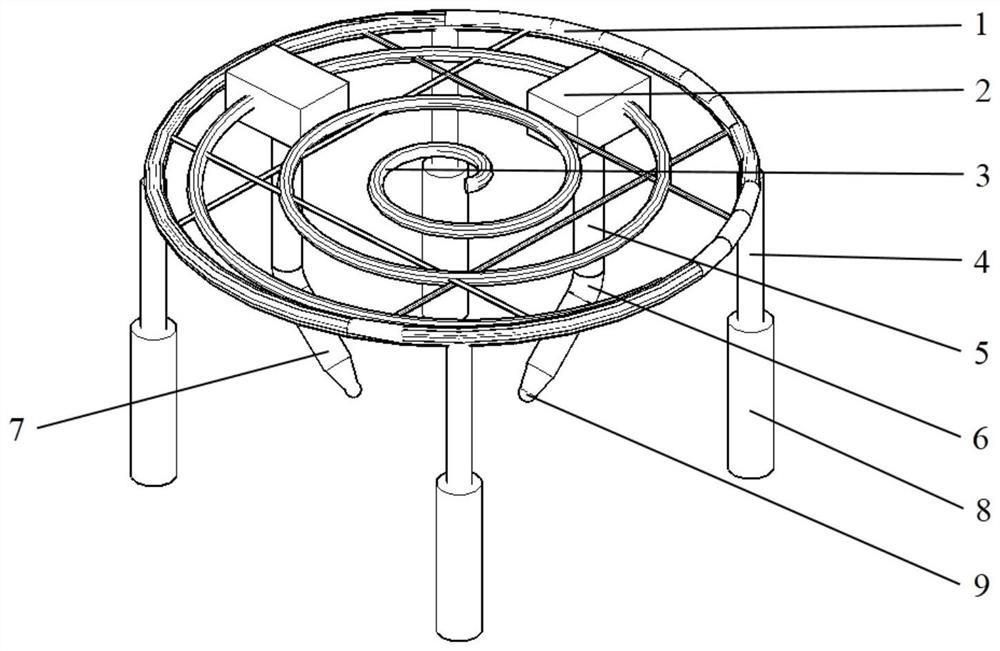

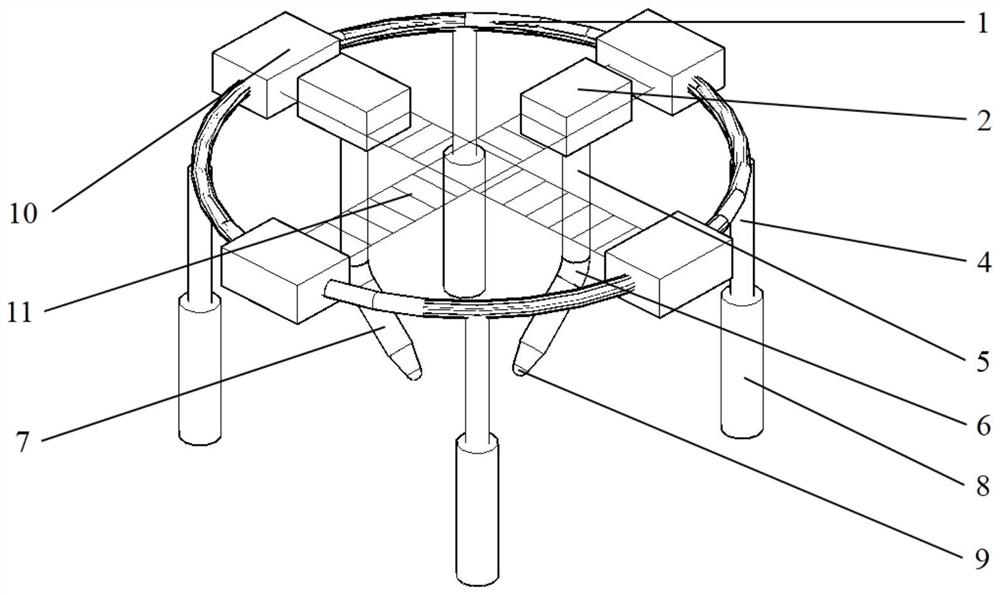

[0035] A general platform equipment for decommissioning nuclear facilities, including a rail platform 1, a manipulator rail car 2, a track, a manipulator 5, a manipulator standardized interface 6, a manipulator 7, an operating tool standardized interface 9, and related operating tools and control systems.

[0036] The orbital platform 1 is composed of a circular track and supporting steel columns, wherein the diameter of the circular track is determined by the horizontal size of the decommissioned reactor, and four or more supporting steel columns are arranged at equal intervals below the circular track. The supporting steel column is composed of an upper supporting column 4 and a lower supporting column 8, both of which are hydraulically connected, and the overall height of the supporting steel column is adjusted through the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com