An industrial design material binding device

A technology for industrial design and mounting boards, which is applied in binding and other directions, and can solve the problems of industrial design material binding troubles, increased work intensity, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

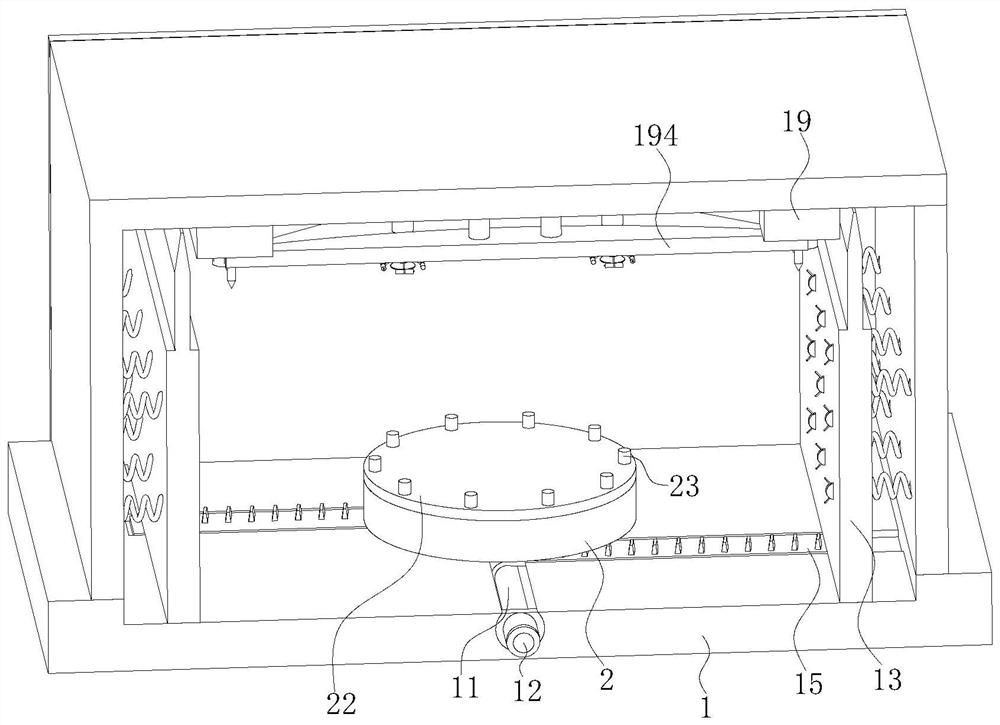

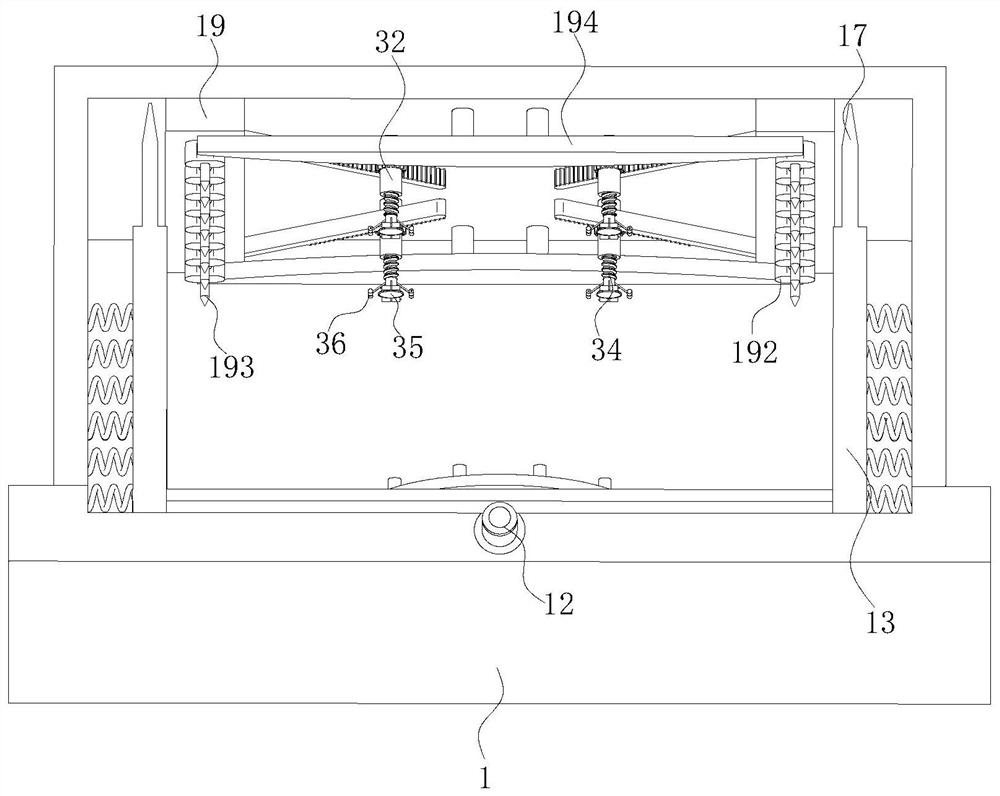

Examples

Embodiment approach

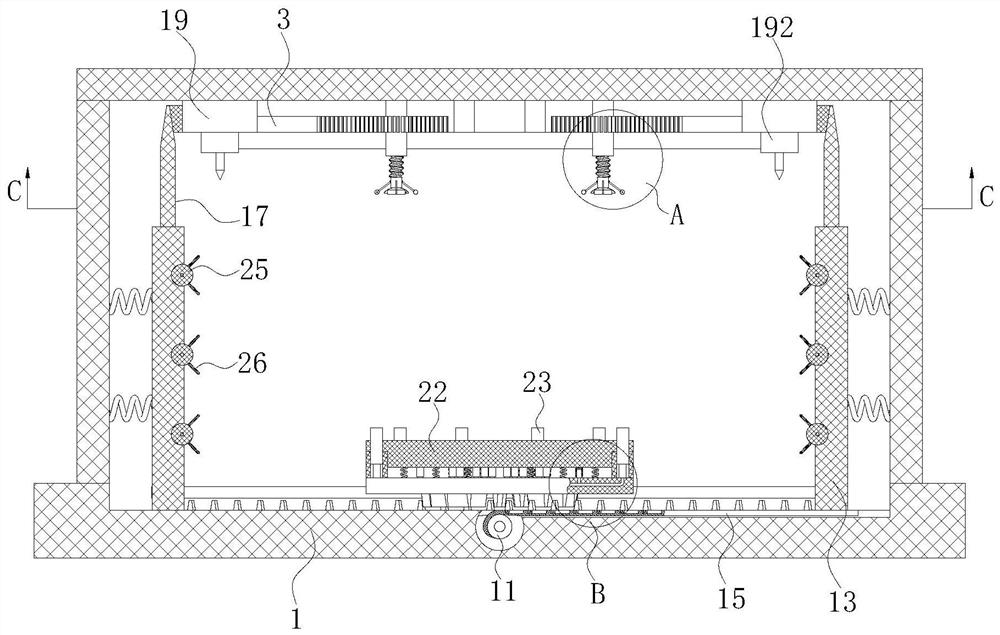

[0038] As an embodiment of the present invention, an annular groove is opened in the inner wall of the support plate 2, and the annular groove is designed around the support plate 2; a disc 22 is slidably connected to the inner wall of the annular groove through evenly arranged springs, and the circular groove is The discs 22 are closely fitted with the circular groove;

[0039] During work, owing to be connected with disc 22 by spring sliding in the supporting disc 2 inner wall, when needing to bind when the case cabinet that industrial design material uses is less, because case case is smaller, relatively lighter in weight relative to case case, here In the process, the supporting force of the cabinet by utilizing the disc 22 that is fixedly connected by the spring is greater, so that the cabinet can be promoted to move upwards. In this process, the height of the cabinet can be prevented from being insufficient, and the cabinet cannot be bound. During the binding process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com