Spinning machine pan head capable of preventing thread disorder

A kind of machine coil head and textile technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of winding disorder, disorder, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

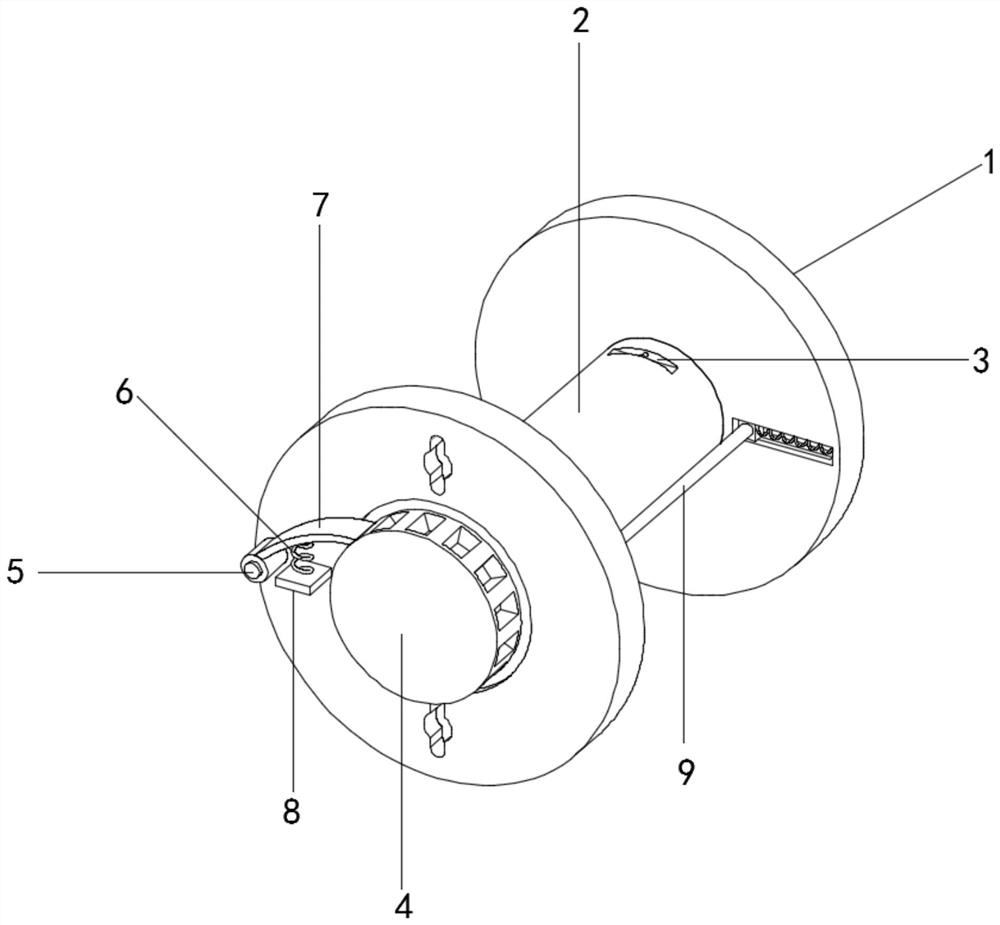

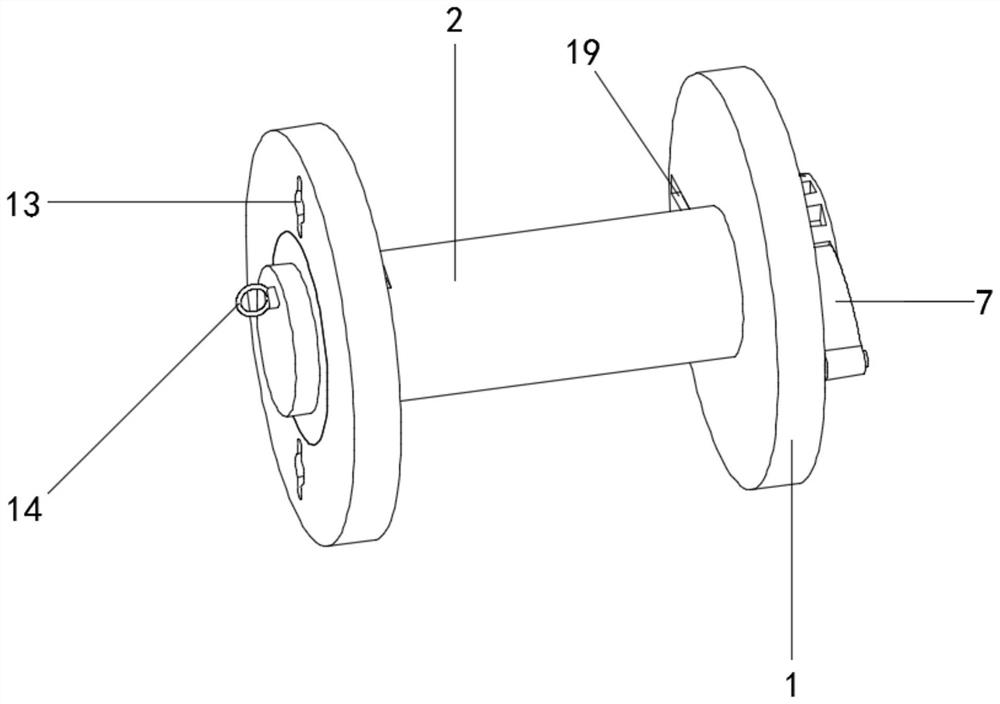

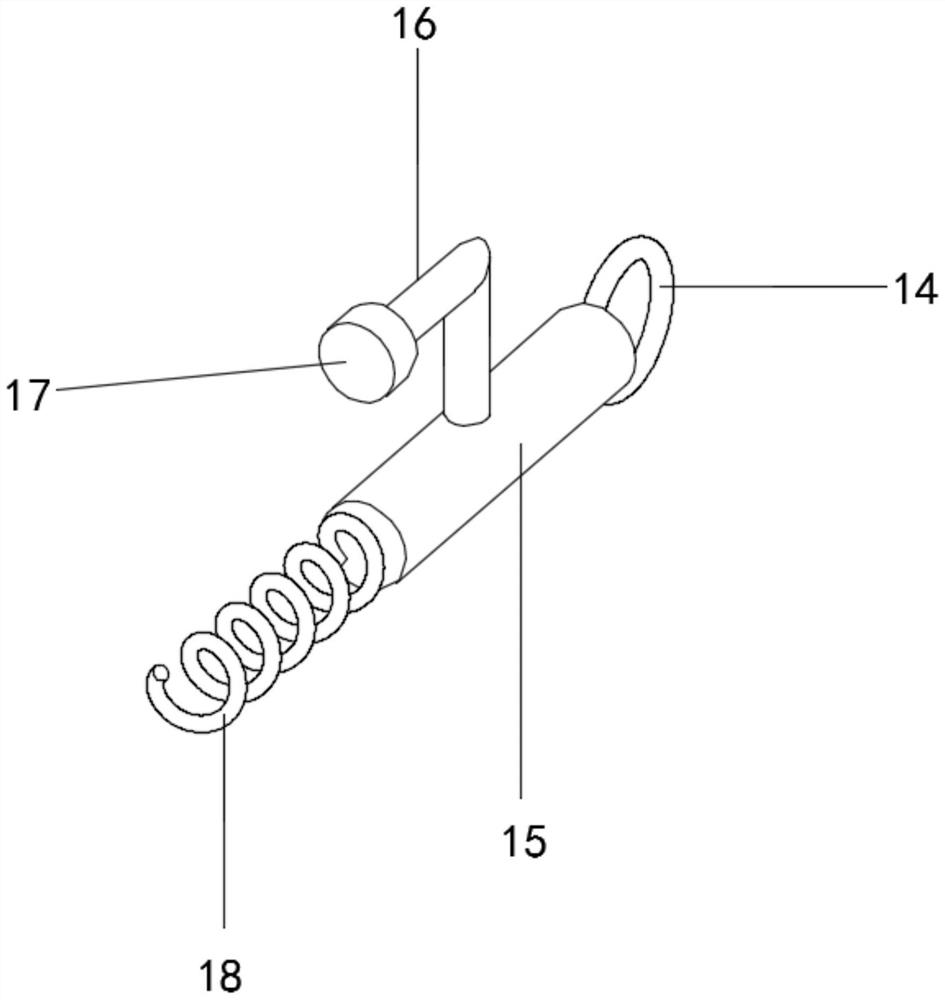

[0028] refer to Figure 1-4 , a textile machine pan head for anti-chaotic threads, comprising a disc 1 and a disc core 2, the disc 1 and the disc core 2 are connected by bearings, a card slot 13 is opened on the outer wall of one side of the disc 1, and one end of the disc core 2 The gear plate 4 is fixed by screws, the outer wall of one side of the disc 1 is provided with a one-way rotation mechanism, the outer wall of one side of the disc 1 is provided with a chute 19, and the inner wall of the chute 19 is connected with a slider 20 by sliding, the slider One side outer wall of 20 is fixed with tension spring 10 by screw, and one end of tension spring 10 is fixedly connected with one side inner wall of chute 19 by screw, and one side outer wall of disk core 2 is provided with placement groove, and the inner wall of placement groove is fixed by screw There is a clamping spring 18, and one end of the clamping spring 18 is fixed with a control mechanism by a screw, and a clampi...

Embodiment 2

[0037] refer to Figure 5 , a textile machine pan head for tamper-proof threads. Compared with Embodiment 1, this embodiment has a cross bar 11 fixed on one side of the outer wall of the disc 1 by screws.

[0038] In the present invention, the outer wall of the cross bar 11 is sleeved with a guide wheel 12 .

[0039] When in use, the staff holds one end of the yarn, winds the yarn on the outer wall of the guide wheel 12, and then clamps one end of the yarn through the block 17, and in the process of winding up the yarn, the position of the yarn head changes. Change guide wheel 12 produces lateral movement on the outer wall of cross bar 11, can make the yarn of keeping certain tension force, prevents disorderly thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com