A Treatment Method for Water Leakage in Segment Joints in Shield Tunnel During Operation Period

A technology for shield tunneling and water leakage, applied in tunnels, tunnel linings, drainage, etc., can solve problems such as loss of waterproof effect, cracks in filling materials, etc., and achieve improved treatment efficiency, high impermeability and elongation, and good leakage repair effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment relates to a treatment method for water leakage at segment joints

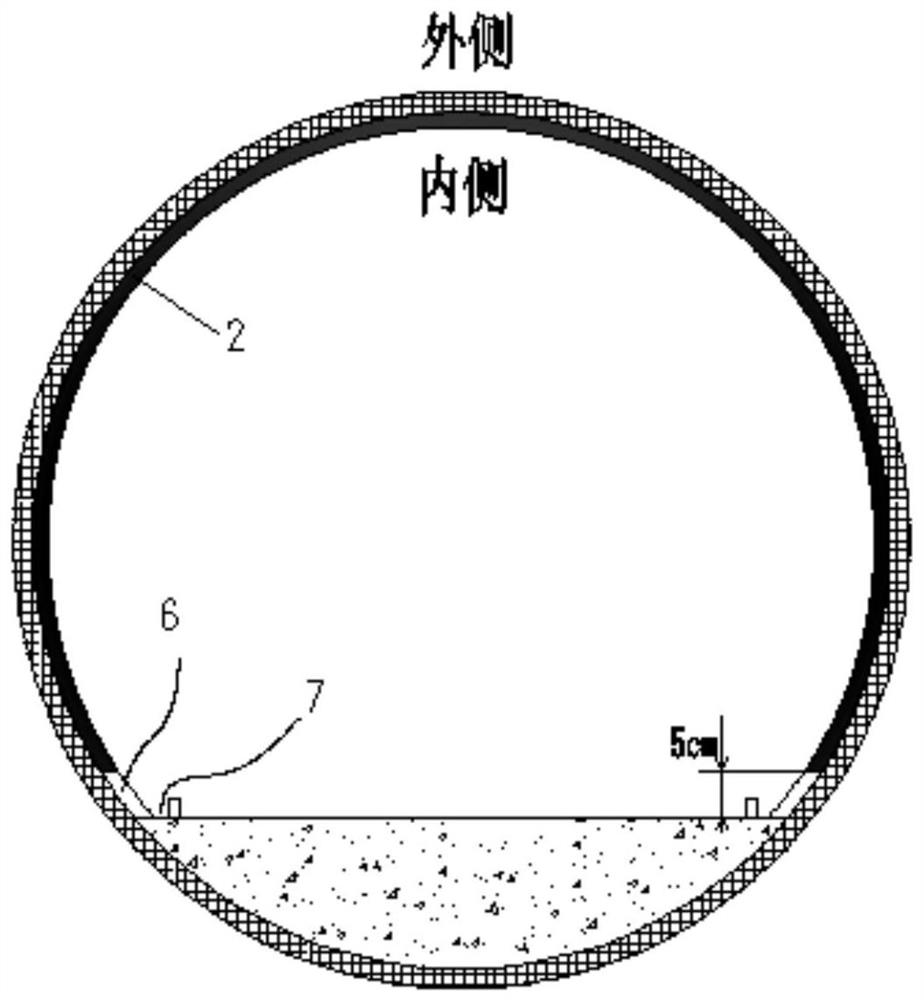

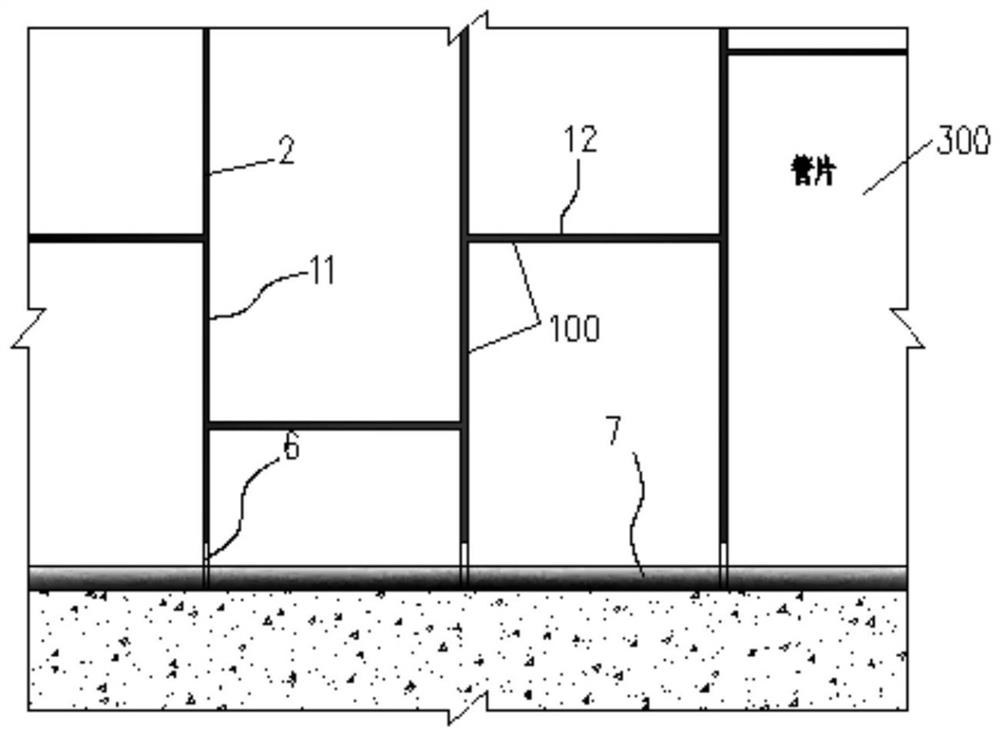

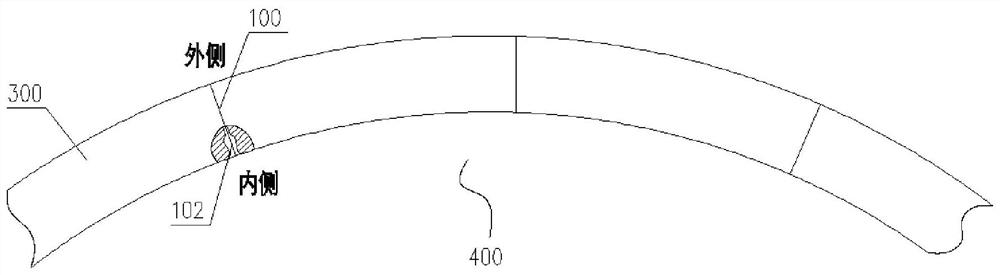

[0037] Such as Figure 1-3 , there is a joint 100 between two adjacent segments 300 in the shield tunnel 400 during an operation period, the segment joint 100 includes a longitudinal joint 12 along the direction of the tunnel and a circumferential direction along the arc direction of the shield tunnel seams11.

[0038] In this embodiment, according to the above-mentioned segment joints in the shield tunnel 400 , the treatment method for joint water leakage includes: cleaning the segment joints, constructing a first leak-trapping sealing layer and building a second leak-trapping sealing layer.

[0039] Cleaning the segment joints is to clean the segment joints in the leaking water area on the inner side of the segment joints, and insert water-swellable water-stop strips 5 into the cleaned segment joints, A grouting chamber 130 is formed on the outer side of the water-expandable water-st...

Embodiment 2

[0050] This embodiment is based on one of the sealing strips 2 used in the method described in Embodiment 1.

[0051] The inner seam structure on the inner side of the segment is as follows: Figure 8 , including a wide slit 102 and a narrow slit 101 arranged from inside to outside, wherein: the narrow slit 101 is formed by two parallel straight wall surfaces 1011; The side wedge-shaped wall surface is formed with two inclined wall surfaces 1021 of the straight wall surface. The straight wall surface 1011, the wedge-shaped wall surface 1022 and the inclined wall surface 1021 are produced by the design structure of the joint side of the segments.

[0052] Such as Figure 9 In the present invention, the sealing strip 2 includes a first body 20 , a second body 21 , a sealing rib 25 and sealing teeth 24 . The second body 20 is disposed at the lower part of the first body 21 and is integrally formed. The width of the second body 21 is greater than that of the first body 20 . Tw...

Embodiment 3

[0060] This embodiment is based on another sealing strip 2 used in the method described in Embodiment 1.

[0061] Such as Figure 11 , Figure 12 , this embodiment also includes a sealing strip 2 and a core 3, the structure of the sealing member 2 is basically the same as that of the above-mentioned embodiment 2, the only difference is that the structure of the insertion groove 211 is different, and the insertion groove 221 is arranged The center of symmetry of the body 21 is formed by several circular holes 212 arranged along the height direction and opening grooves 213 connecting the several circular holes. The corresponding core 3 is a bar with a T-shaped cross-section composed of horizontal plates and vertical plates, and the core 3 is inserted into the insertion groove 211 through the vertical plates.

[0062] Other structures of this embodiment are the same as those of Embodiment 2 and have the same performance and effect, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com