Concrete cable trench cover plate manufacturing and carrying device

A technology of cable trench cover and handling device, which is applied in the direction of cable installation, ground cable installation, hoisting device, etc. It can solve the problems of time-consuming and labor-intensive production and maintenance, and long construction period for transportation, so as to save manpower, shorten construction period, The effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

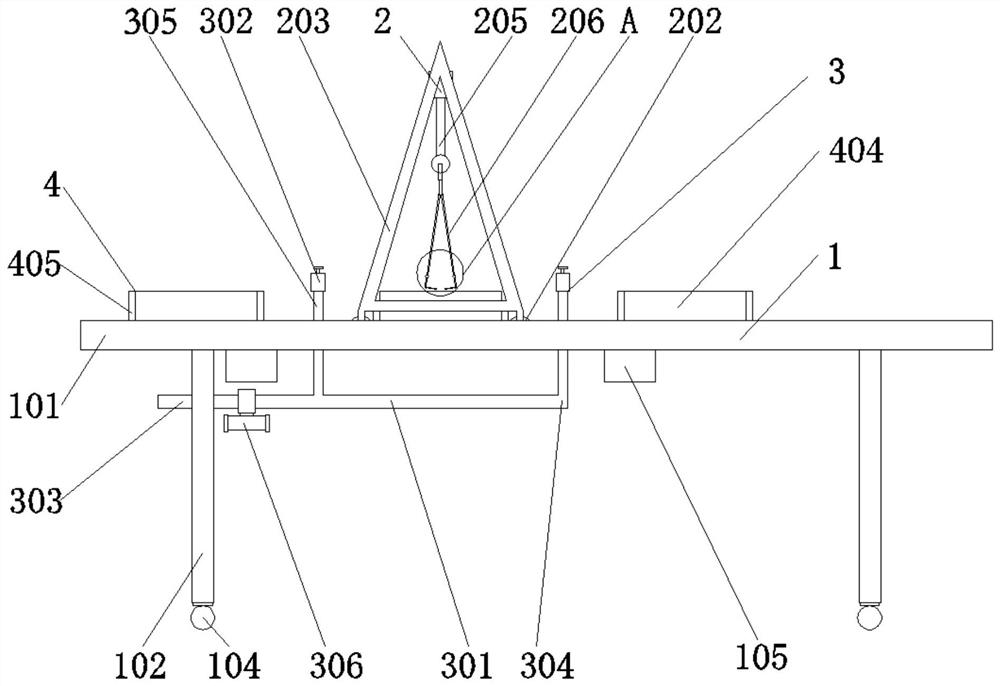

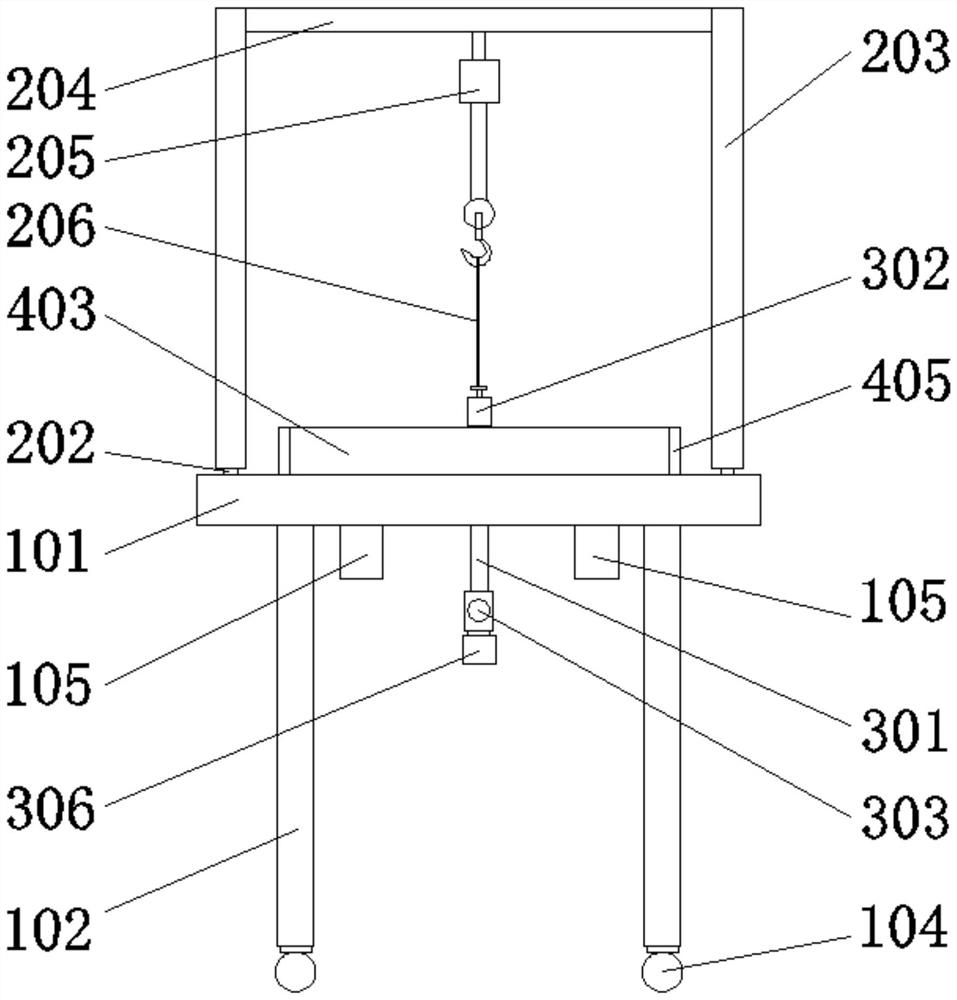

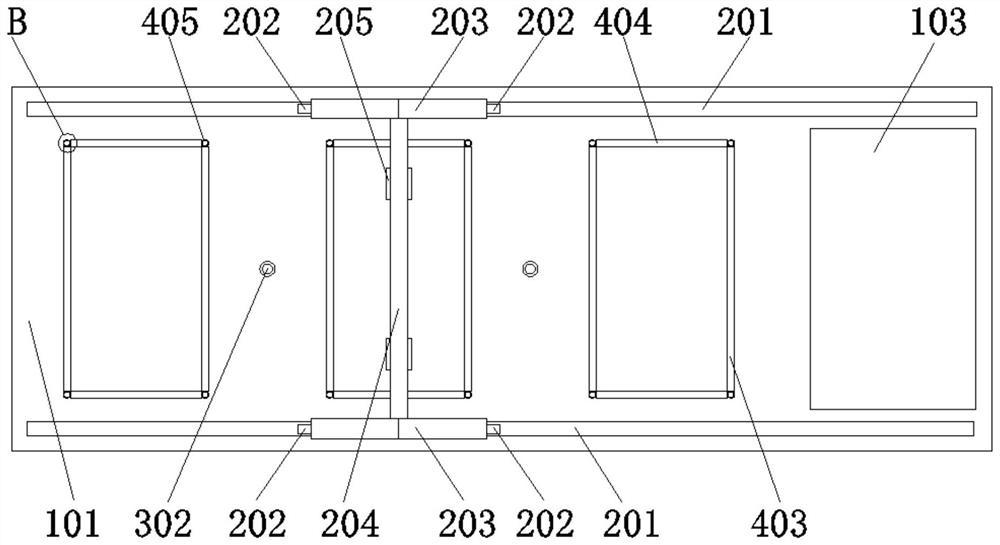

[0032] refer to Figure 1-6 , the present invention provides a technical solution, a concrete cable trench cover production and handling device, including a support part 1, a handling part 2, a sprinkler part 3 and at least one mold part 4;

[0033] The support part 1 includes a platform 101 and a support column 102 fixed at the bottom of the platform 101, and an opening 103 is opened at one end of the platform 101; the support part 1 plays a role of moving and supporting;

[0034] Carrying part 2 comprises chute 201, first caster 202, tripod 203, crossbeam 204, crane 205, hoisting rope 206 and catcher 207, and chute 201 is arranged on the front and back ends of platform 101, and chute 201 is provided with Two first casters 202, a tripod 203 is fixed on the two first casters 202, a crossbeam 204 is fixed between the tops of the two tripods 203, a crane 205 is fixed at the bottom of the crossbeam 204, and the middle of the lifting rope 206 is connected with the crane 205 , the...

Embodiment 2

[0039] refer to Figure 1-6 , the present invention provides a technical solution, a concrete cable trench cover production and handling device, including a support part 1, a handling part 2, a sprinkler part 3 and at least one mold part 4;

[0040] The support part 1 includes a platform 101 and a support column 102 fixed at the bottom of the platform 101, and an opening 103 is opened at one end of the platform 101; the support part 1 plays a role of moving and supporting;

[0041] Carrying part 2 comprises chute 201, first caster 202, tripod 203, crossbeam 204, crane 205, hoisting rope 206 and catcher 207, and chute 201 is arranged on the front and back ends of platform 101, and chute 201 is provided with Two first casters 202, a tripod 203 is fixed on the two first casters 202, a crossbeam 204 is fixed between the tops of the two tripods 203, a crane 205 is fixed at the bottom of the crossbeam 204, and the middle of the lifting rope 206 is connected with the crane 205 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com