Optical glass

A technology of optical glass and optical components, applied in the field of high-refractive and high-dispersion optical glass, can solve the problems of glass crystallization scrap, large crystallization risk, poor anti-crystallization performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115]

[0116] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

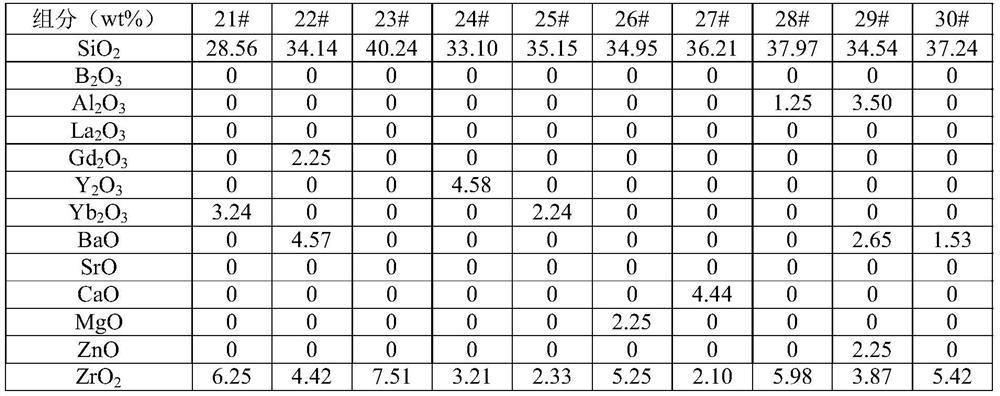

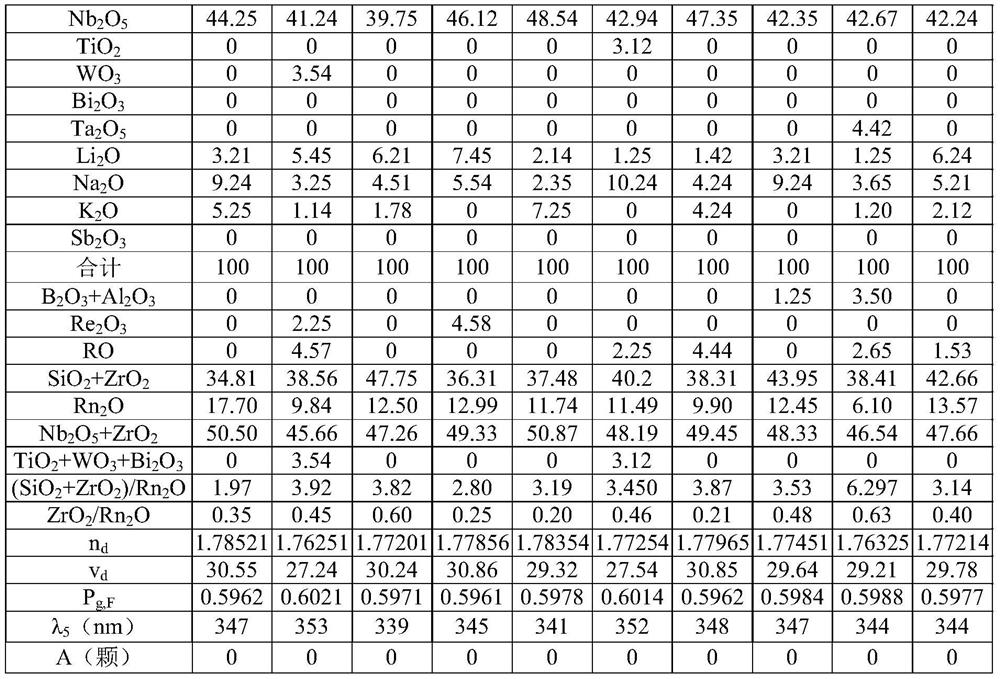

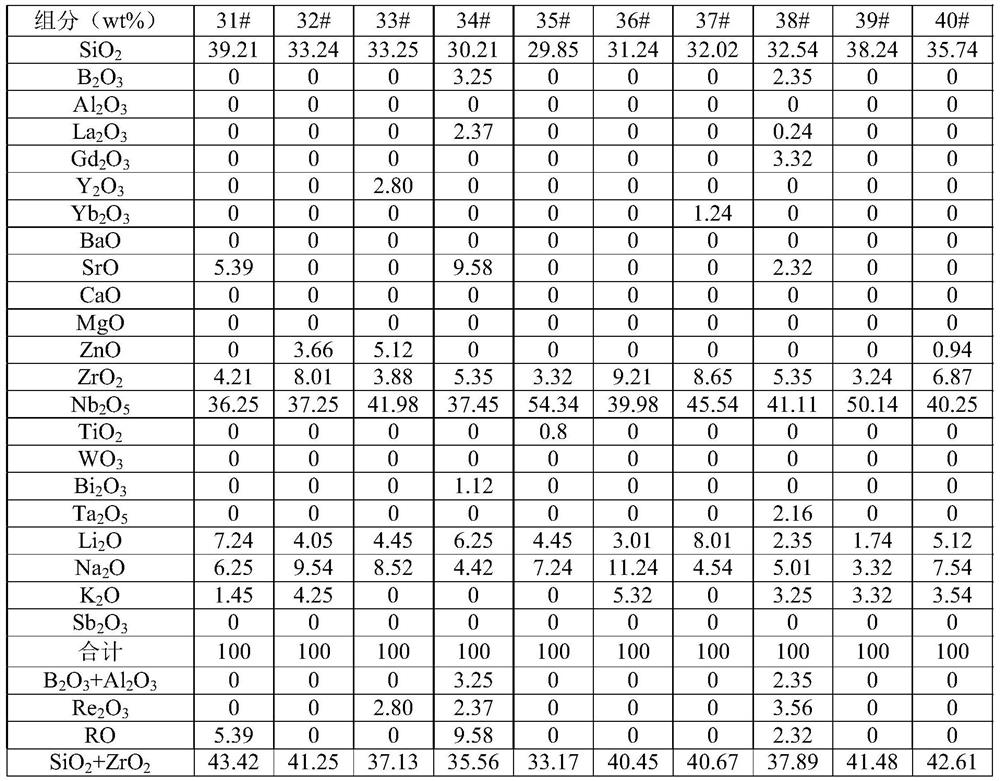

[0117] In this example, the above-mentioned method of manufacturing optical glass was used to obtain optical glasses having Tables 1 to 4 shown. In addition, the characteristics of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 1 to 4.

[0118] Table 1.

[0119] Component (wt%) 1#2#3#4#5#6#7#8#9#10# SiO 2

35.2436.5426.2538.0132.1425.8644.2432.4529.8528.32 B 2 O 3

0.210001.2700000 Al 2 O 3

0000000000 La 2 O 3

00002.3500000 Gd 2 O 3

00001.2400008.21 Y 2 O 3

00081.340.690000 Yb 2 O 3

0000000000 BaO 009.250000000 SrO 00000.5400000 CaO 0.550000009.7504.52 MgO 00000.4700001 ZnO 0000000001.25 ZrO 2

6.354.254.2510.246.547.582.242.983.259.35 Nb 2 O 5

43.2137.2537.4235.4536.8744.2540.2546.7856.2541.25 TiO 2

08.654.61005.250.781.2400 WO 3

00000000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com