Method for preparing artificial high-strength lightweight aggregate ceramsite sand by utilizing perlite

A technology of ceramsite sand and lightweight aggregate, which is applied in the preparation of ceramsite sand and artificial lightweight aggregate high-strength ceramsite, which can solve the problems of difficult application of structural concrete, low cylinder compressive strength, increased energy consumption, etc., and achieve a large design direction Performance and flexibility, lower production costs, lower apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

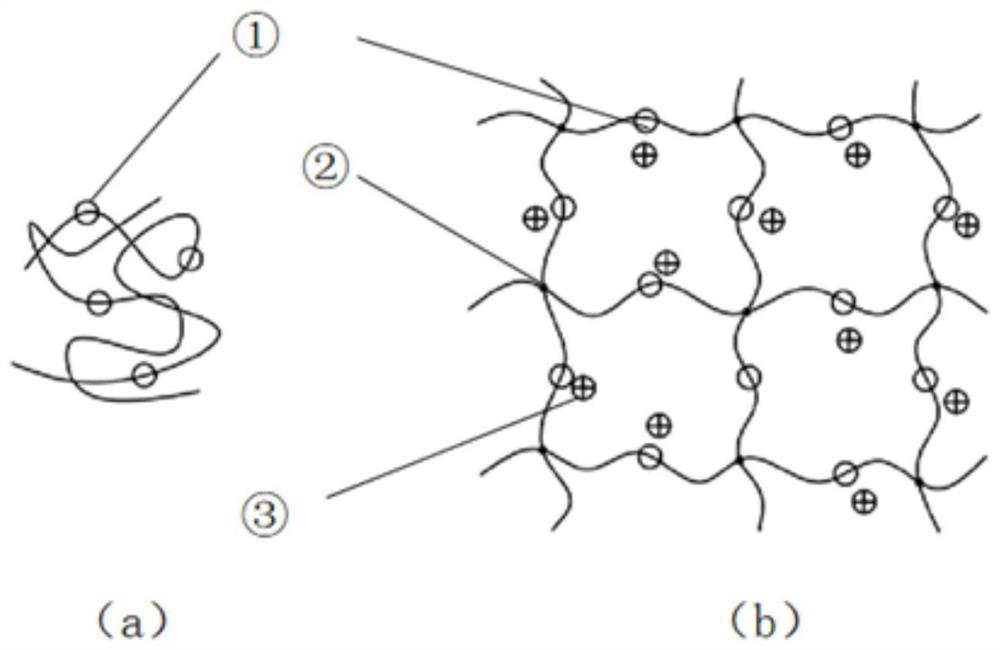

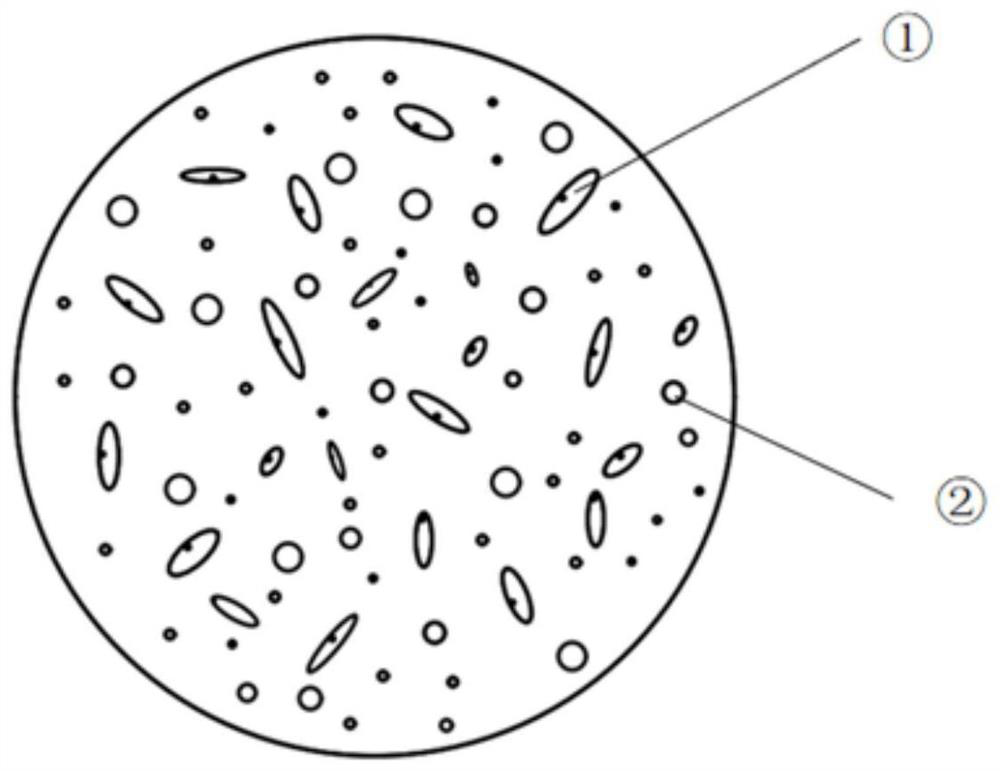

Method used

Image

Examples

Embodiment 1

[0084] 1. Known cement density ρ 水泥 =3150kg / m 3 , expanded perlite particle size 0.1-1.5mm, apparent density ρ 珍珠岩 =348kg / m 3 , fly ash apparent density ρ 粉煤灰 =2200kg / m 3 , Density ρ of absorbent resin 吸水树脂 ≈1000kg / m 3

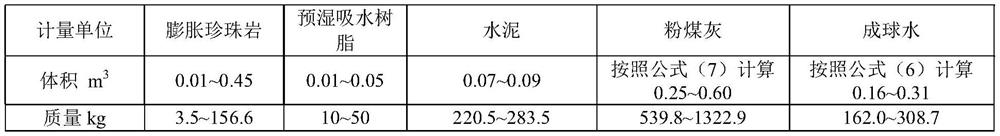

[0085] In this embodiment, the amount of each material used per cubic meter is used as the basis for calculation, and the volume ratio and addition amount of each raw material are shown in Table 2 below.

[0086] In table 2 embodiment 1, each material admixture per cubic meter, unit kg, m 3

[0087]

[0088] The formula is calculated theoretically to obtain the finished ceramsite sand, and the apparent density of the ceramsite sand is 1782.23kg / m 3 .

[0089] 2. First take 0.01m 3 The expanded perlite is pre-wetted to reach saturation and the surface is dry for later use, according to 0.07m 3 Weigh cement by volume fraction, weigh 50kg of pre-wet water-absorbent resin (absorb water more than 20 times its own mass), calculate the amount of fly as...

Embodiment 2

[0099] 1. Known cement density ρ 水泥 =3150kg / m 3 , expanded perlite particle size 0.1-1.5mm, apparent density ρ 珍珠岩 =348kg / m 3 , fly ash apparent density ρ 粉煤灰 =2200kg / m 3 , Density ρ of absorbent resin 吸水树脂 ≈1000kg / m 3

[0100] Each material of the present invention cooperates and adopts the consumption per cubic meter as calculation basis, and wherein each raw material volume ratio and admixture are as follows Table 3.

[0101] The amount of each material added per cubic meter in the embodiment 2 of table 3, unit kg, m 3

[0102]

[0103] The formula is calculated theoretically to obtain the finished ceramsite sand, and the apparent density of the ceramsite sand is 1488.67kg / m 3 .

[0104] 2. First take 0.25m 3 The expanded perlite is pre-wetted to reach saturation and the surface is dry for later use, according to 0.08m 3 The volume fraction weighs cement, weighs 20kg of pre-wet water-absorbing resin (water-retaining state), and calculates the amount of fly as...

Embodiment 3

[0113] 1. Known cement density ρ 水泥 =3150kg / m 3 , perlite particle size 0.1-1.5mm, apparent density ρ 珍珠岩 =348kg / m 3 , fly ash apparent density ρ 粉煤灰 =2200kg / m 3 , Density ρ of absorbent resin 吸水树脂 ≈1000kg / m 3

[0114] Each material of the present invention cooperates and adopts the consumption per cubic meter as calculation basis, and wherein each raw material volume ratio and admixture are as follows table 4.

[0115] Each material admixture per cubic meter in table 4 embodiment 3, unit kg, m 3

[0116]

[0117] The formula is calculated theoretically to obtain the finished ceramsite sand, and the apparent density of the ceramsite sand is 1217.85kg / m 3 .

[0118] 2. First take 0.45m 3 The expanded perlite is pre-wetted to reach saturation and the surface is dry for later use, according to 0.09m 3 The volume fraction weighs cement, weighs 10kg of pre-wet water-absorbing resin (water-retaining state), and calculates the amount of fly ash according to the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com