Spectral splitting-based condensation pyrolysis catalytic reforming system and method

A pyrolysis catalysis and reforming system technology, applied in the field of new energy utilization, can solve problems such as affecting the normal operation of equipment, contamination of concentrating components, affecting biomass absorption, etc., to ensure long-term efficient operation, guarantee stability and safety, Realize the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The spectrum splitting-based concentrating pyrolysis catalytic reforming system and method involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

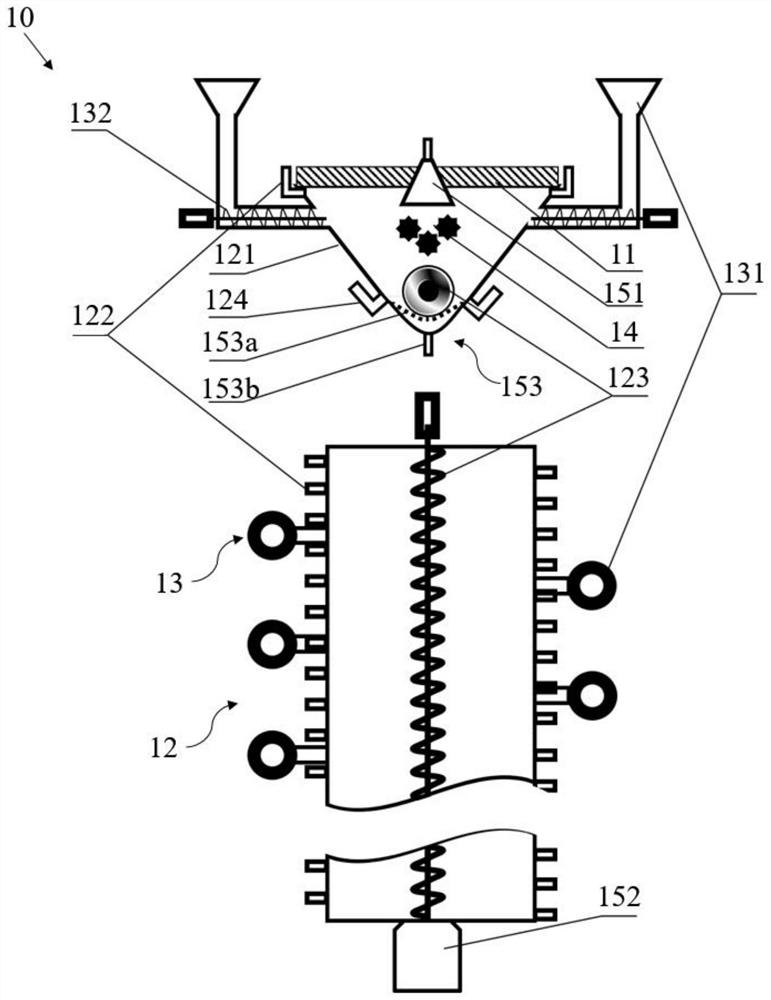

[0025] Such as figure 1 As shown, the spectral splitting based concentrating pyrolysis catalytic reforming system 10 includes a concentrating device 11 , a pyrolysis reactor 12 , a feeding device 13 , a photocatalytic reforming device 14 , a collecting device and a controller.

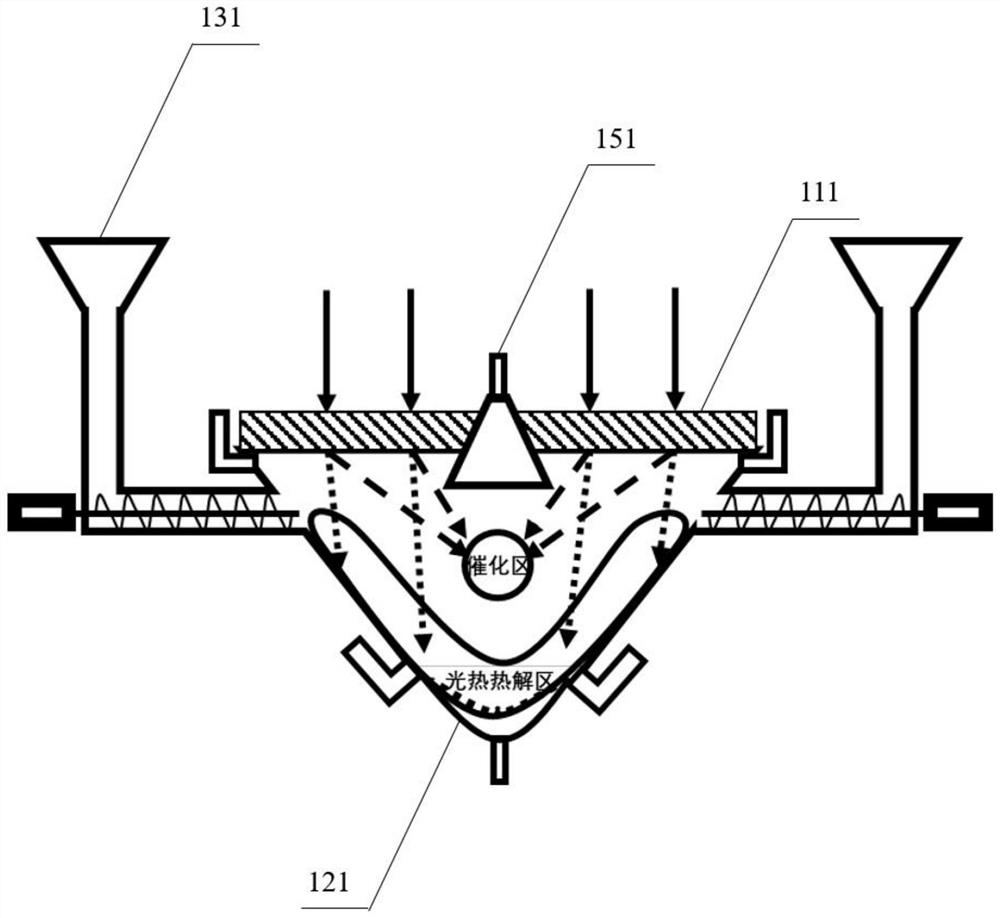

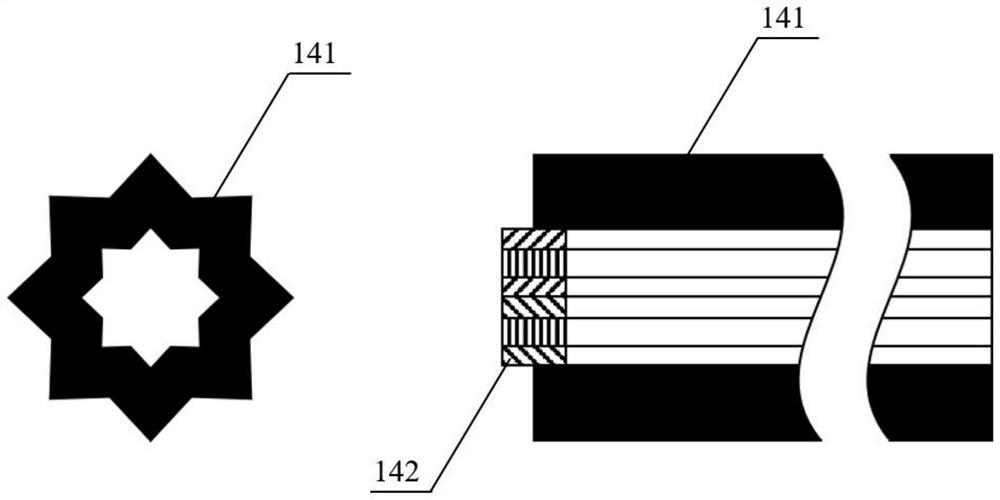

[0026] Such as figure 1 and 2 As shown, the light concentrating device 11 can gather sunlight, and utilize the difference in refractive index of light of different wavelengths to form a catalytic zone where ultraviolet light is relatively concentrated, and a catalytic zone where infrared and near-infrared light are relatively concentrated on the light concentrating side (below the lens in the figure). Photothermal pyrolysis zone. The concentrating device 11 includes a high concen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap