Method for purifying indium from indium-tin alloy

An indium-tin alloy and metal technology, applied in the field of separation and recovery of rare alloys, can solve problems such as high labor costs, high processing costs, and complicated processes, and achieve the effects of reducing processing costs, reducing labor costs, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with embodiment.

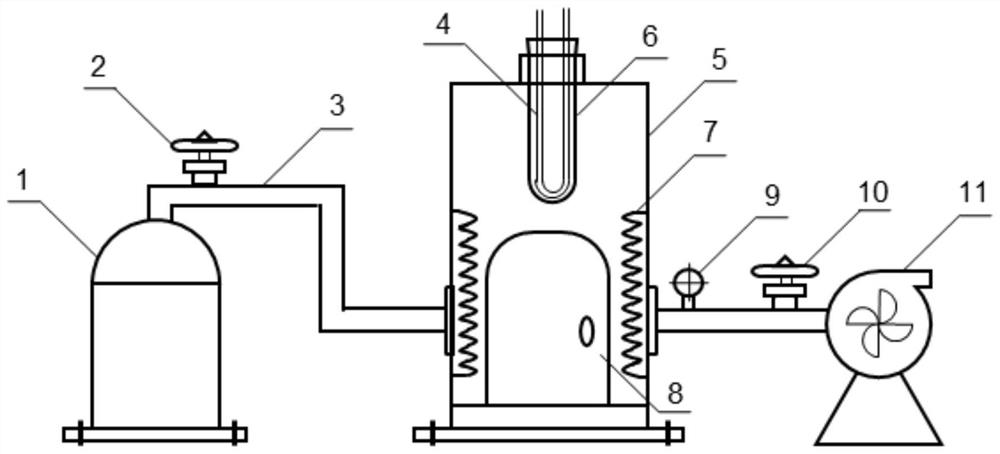

[0025] Such as figure 1 As shown, a kind of indium-tin alloy purification device provided by the present invention includes a vacuum furnace 5 providing a purification reaction place, and the vacuum furnace 5 has a door 8, N 2 The gas cylinder 1 and the vacuum pump 11 are respectively connected to the vacuum furnace 5 through a pipeline provided with a ball valve switch. The vacuum furnace 5 is provided with a heating device 7 for heating the alloy, and an indium metal recovery target 6 is provided on the top of the vacuum furnace 5. It also includes A cooling device 4 for cooling the indium metal recovery target 6 and a vacuum gauge 9 are arranged on the pipeline connecting the vacuum pump 11 and the vacuum furnace 5 .

[0026] In the embodiment, the indium tin alloy is put into the heating device 7 in the vacuum furnace for heat treatment; the heating device 7 is an electric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap