Construction process for simply plugging outer wall reserved sleeve in underground structure area

A technology of underground structure and construction technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problem of not being able to reserve casings closely, and achieve the effect of reducing labor consumption, facilitating construction, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

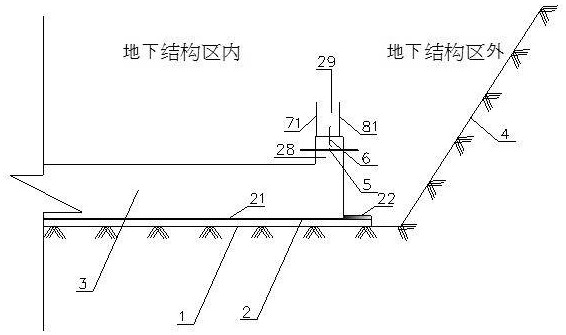

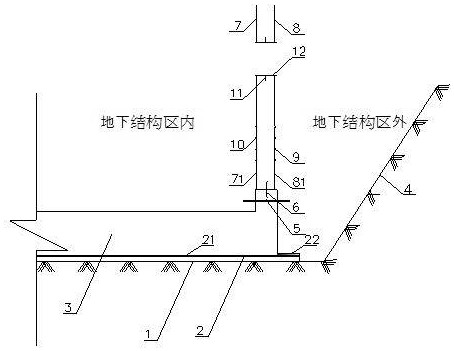

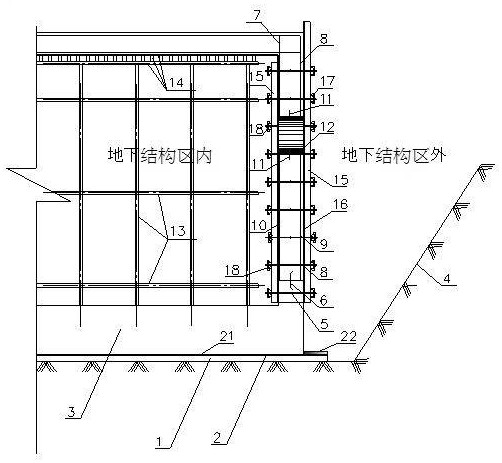

[0038] Such as Figure 1-9 As shown, the present invention relates to a construction technique for simple sealing of casings reserved for outer walls in underground structure areas, comprising the following steps:

[0039]Step 1: According to the construction rules of the underground structure, the earthwork excavation of the foundation pit is completed in order to form the elevation line 1 at the bottom of the foundation pit and the slope control line 4, and the pouring of the concrete cushion layer 2, the laying of the waterproof layer 21 under the raft slab, and the laying of the raft slab 3 Concrete Rebar Binding. Mark the position of the outer wall column 29 on the steel bars of the raft 3 according to the design, and pre-insert the vertical reinforcement 71 of the inner reinforcement mesh of the outer wall panel and the vertical reinforcement 81 of the outer reinforcement mesh at the calibrated location of the outer wall column 29 , set a construction joint for exterior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com