Pipe jacking relay jacking conversion device and construction method

A construction method and conversion device technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of short construction section distance, increase construction continuity, and extend jacking construction intervals, etc. Reach the effect of reducing the project cost and reducing the structural strength of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

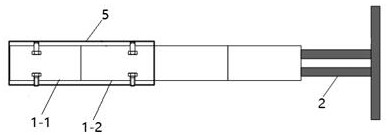

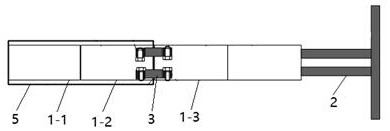

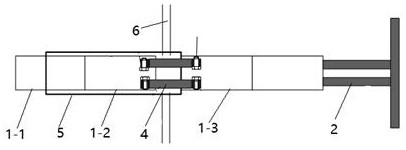

[0029] Depend on Figure 1-7 Shown, a kind of pipe jacking relay jacking construction method, concrete steps are:

[0030] Step 1: Bolt holes are opened on the side walls of the front and rear ends of the jacking pipeline 1, and then the casing 5 is sleeved on the periphery of the jacking pipeline Ⅰ1-1 and the jacking pipeline Ⅱ1-2 behind the prefabricated pipeline, and the bolts are used to connect firmly. Use the main push jack 2 to jack the prefabricated pipeline, the jacking pipeline I1-1, the jacking pipeline II1-2, and the casing 5 to the predetermined position. As an optimization, 8 bolt holes are opened, and 4 holes are opened at the front end of the jacking pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com