Method for determining flexural capacity of light ultra-high performance concrete beam

An ultra-high performance, concrete beam technology, applied in special data processing applications, instruments, electrical digital data processing, etc. problem, to achieve the effect of simple calculation formula and great practical engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the present invention.

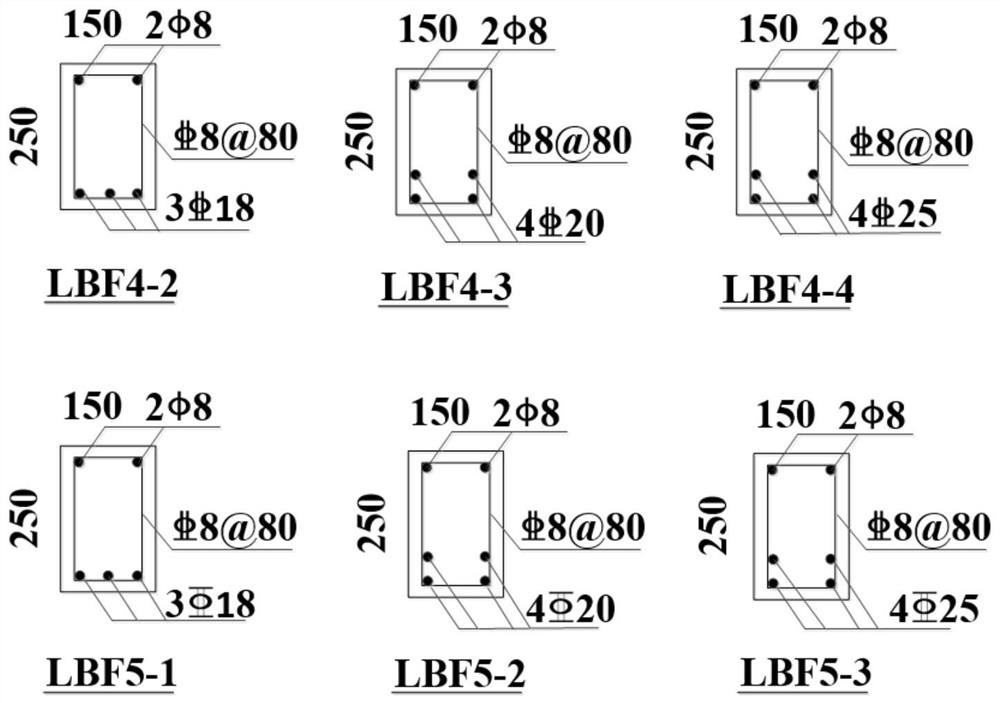

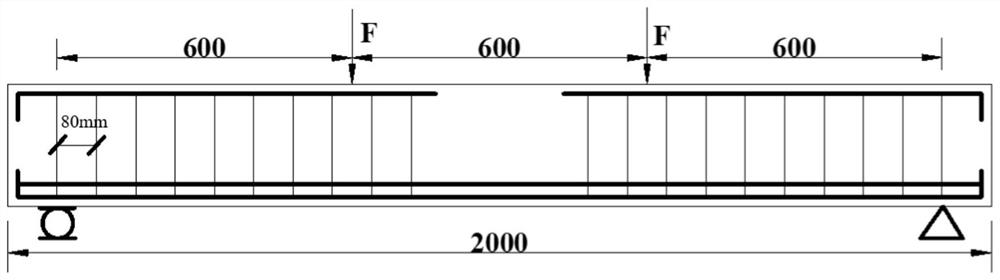

[0028] LUHPC beam reinforcement and section size design such as figure 2 , image 3 As shown in Fig. 4, loading and measuring point layout.

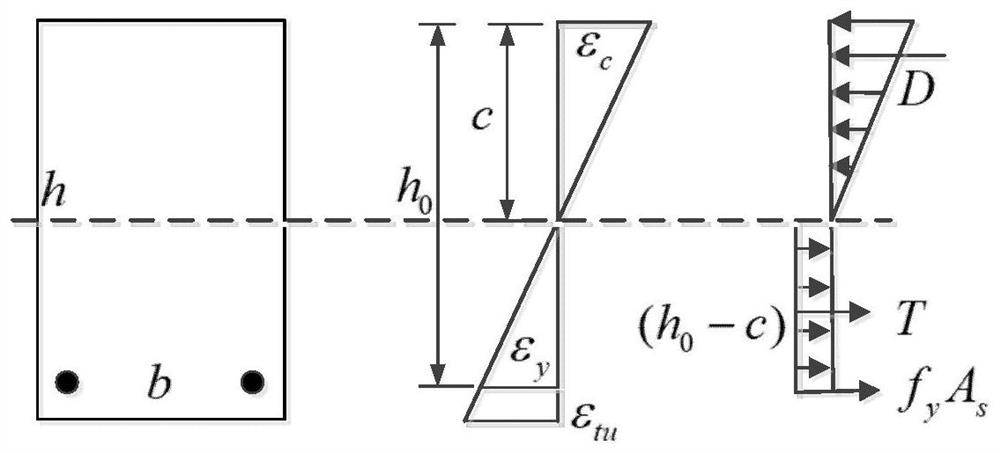

[0029] The method for determining the flexural capacity of lightweight ultra-high performance concrete beams comprises the following steps: testing the section width and section height of lightweight ultra-high performance concrete (Lightweight Ultra-High Performance Concrete, referred to as LUHPC) beams, and testing the lightweight ultra-high performance concrete ( The axial compressive strength of LUHPC), the tensile strength of LUHPC, the yield strength of longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com